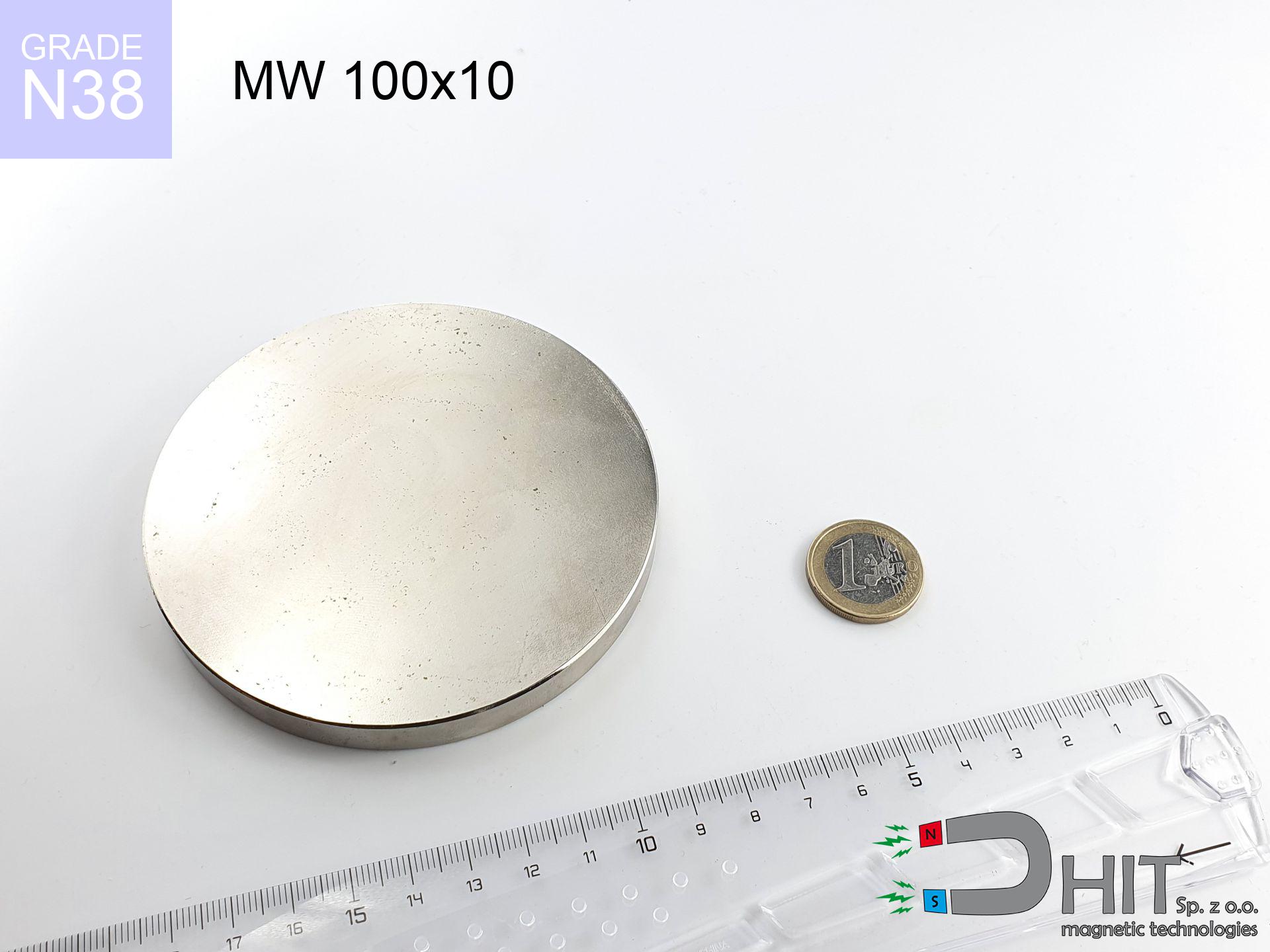

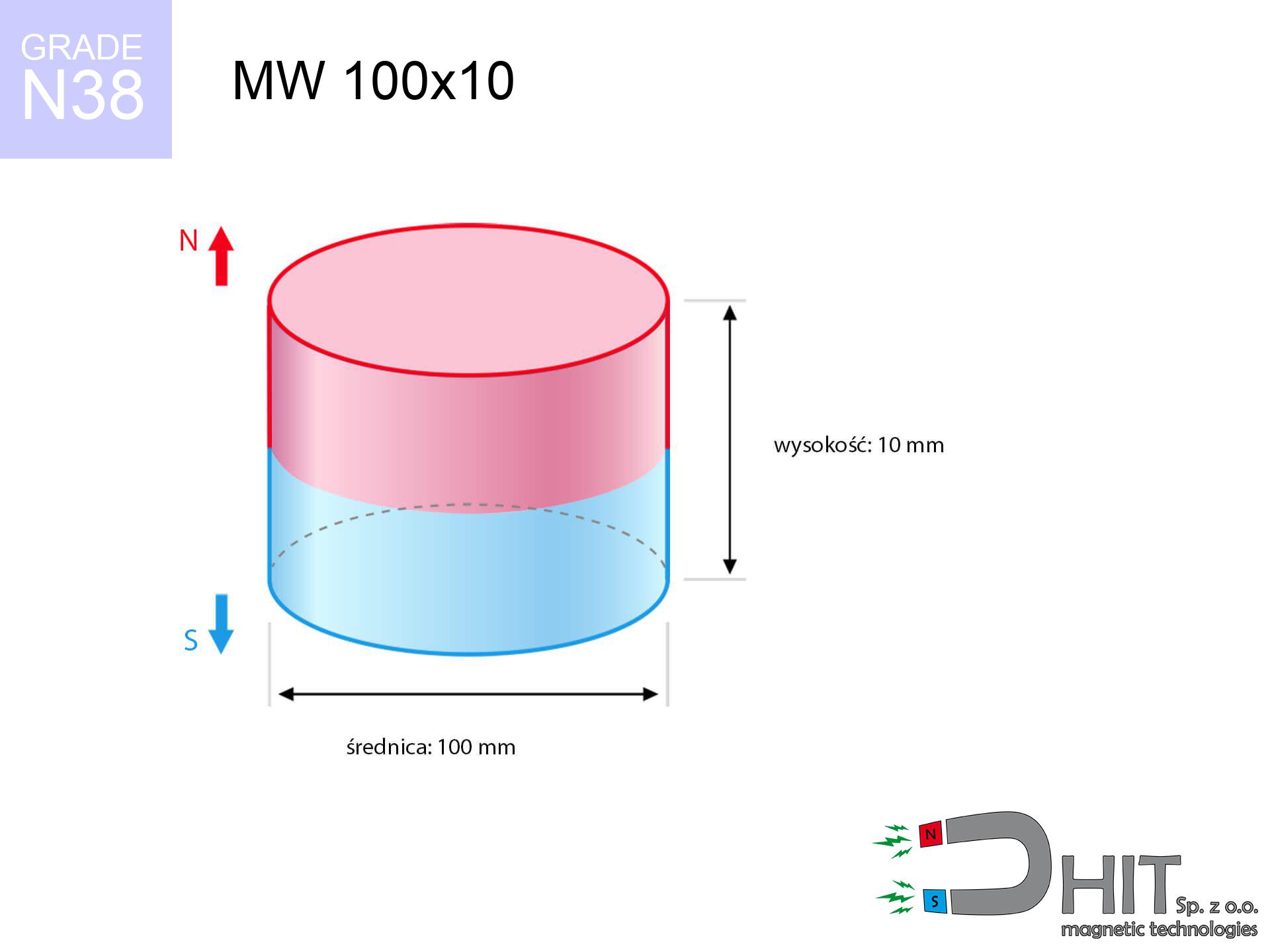

MW 100x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010001

GTIN/EAN: 5906301810018

Diameter Ø

100 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

589.05 g

Magnetization Direction

↑ axial

Load capacity

40.86 kg / 400.80 N

Magnetic Induction

121.59 mT / 1216 Gs

Coating

[NiCuNi] Nickel

368.50 ZŁ with VAT / pcs + price for transport

299.59 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

alternatively let us know through

inquiry form

the contact section.

Specifications along with appearance of a magnet can be estimated with our

our magnetic calculator.

Order by 14:00 and we’ll ship today!

Physical properties - MW 100x10 / N38 - cylindrical magnet

Specification / characteristics - MW 100x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010001 |

| GTIN/EAN | 5906301810018 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 100 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 589.05 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 40.86 kg / 400.80 N |

| Magnetic Induction ~ ? | 121.59 mT / 1216 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the product - technical parameters

Presented values represent the direct effect of a mathematical calculation. Values were calculated on models for the material Nd2Fe14B. Real-world conditions might slightly deviate from the simulation results. Treat these data as a preliminary roadmap during assembly planning.

Table 1: Static pull force (force vs gap) - power drop

MW 100x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1216 Gs

121.6 mT

|

40.86 kg / 90.08 lbs

40860.0 g / 400.8 N

|

critical level |

| 1 mm |

1208 Gs

120.8 mT

|

40.35 kg / 88.95 lbs

40345.4 g / 395.8 N

|

critical level |

| 2 mm |

1199 Gs

119.9 mT

|

39.74 kg / 87.62 lbs

39742.7 g / 389.9 N

|

critical level |

| 3 mm |

1189 Gs

118.9 mT

|

39.06 kg / 86.12 lbs

39062.0 g / 383.2 N

|

critical level |

| 5 mm |

1165 Gs

116.5 mT

|

37.49 kg / 82.65 lbs

37490.2 g / 367.8 N

|

critical level |

| 10 mm |

1087 Gs

108.7 mT

|

32.64 kg / 71.96 lbs

32640.7 g / 320.2 N

|

critical level |

| 15 mm |

991 Gs

99.1 mT

|

27.15 kg / 59.86 lbs

27153.9 g / 266.4 N

|

critical level |

| 20 mm |

887 Gs

88.7 mT

|

21.76 kg / 47.97 lbs

21758.7 g / 213.5 N

|

critical level |

| 30 mm |

683 Gs

68.3 mT

|

12.90 kg / 28.45 lbs

12902.7 g / 126.6 N

|

critical level |

| 50 mm |

379 Gs

37.9 mT

|

3.97 kg / 8.75 lbs

3968.4 g / 38.9 N

|

medium risk |

Table 2: Slippage hold (vertical surface)

MW 100x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

8.17 kg / 18.02 lbs

8172.0 g / 80.2 N

|

| 1 mm | Stal (~0.2) |

8.07 kg / 17.79 lbs

8070.0 g / 79.2 N

|

| 2 mm | Stal (~0.2) |

7.95 kg / 17.52 lbs

7948.0 g / 78.0 N

|

| 3 mm | Stal (~0.2) |

7.81 kg / 17.22 lbs

7812.0 g / 76.6 N

|

| 5 mm | Stal (~0.2) |

7.50 kg / 16.53 lbs

7498.0 g / 73.6 N

|

| 10 mm | Stal (~0.2) |

6.53 kg / 14.39 lbs

6528.0 g / 64.0 N

|

| 15 mm | Stal (~0.2) |

5.43 kg / 11.97 lbs

5430.0 g / 53.3 N

|

| 20 mm | Stal (~0.2) |

4.35 kg / 9.59 lbs

4352.0 g / 42.7 N

|

| 30 mm | Stal (~0.2) |

2.58 kg / 5.69 lbs

2580.0 g / 25.3 N

|

| 50 mm | Stal (~0.2) |

0.79 kg / 1.75 lbs

794.0 g / 7.8 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MW 100x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

12.26 kg / 27.02 lbs

12258.0 g / 120.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

8.17 kg / 18.02 lbs

8172.0 g / 80.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

4.09 kg / 9.01 lbs

4086.0 g / 40.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

20.43 kg / 45.04 lbs

20430.0 g / 200.4 N

|

Table 4: Steel thickness (saturation) - power losses

MW 100x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

2.04 kg / 4.50 lbs

2043.0 g / 20.0 N

|

| 1 mm |

|

5.11 kg / 11.26 lbs

5107.5 g / 50.1 N

|

| 2 mm |

|

10.22 kg / 22.52 lbs

10215.0 g / 100.2 N

|

| 3 mm |

|

15.32 kg / 33.78 lbs

15322.5 g / 150.3 N

|

| 5 mm |

|

25.54 kg / 56.30 lbs

25537.5 g / 250.5 N

|

| 10 mm |

|

40.86 kg / 90.08 lbs

40860.0 g / 400.8 N

|

| 11 mm |

|

40.86 kg / 90.08 lbs

40860.0 g / 400.8 N

|

| 12 mm |

|

40.86 kg / 90.08 lbs

40860.0 g / 400.8 N

|

Table 5: Working in heat (stability) - resistance threshold

MW 100x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

40.86 kg / 90.08 lbs

40860.0 g / 400.8 N

|

OK |

| 40 °C | -2.2% |

39.96 kg / 88.10 lbs

39961.1 g / 392.0 N

|

OK |

| 60 °C | -4.4% |

39.06 kg / 86.12 lbs

39062.2 g / 383.2 N

|

|

| 80 °C | -6.6% |

38.16 kg / 84.14 lbs

38163.2 g / 374.4 N

|

|

| 100 °C | -28.8% |

29.09 kg / 64.14 lbs

29092.3 g / 285.4 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MW 100x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

71.58 kg / 157.80 lbs

2 302 Gs

|

10.74 kg / 23.67 lbs

10737 g / 105.3 N

|

N/A |

| 1 mm |

71.15 kg / 156.86 lbs

2 424 Gs

|

10.67 kg / 23.53 lbs

10673 g / 104.7 N

|

64.04 kg / 141.17 lbs

~0 Gs

|

| 2 mm |

70.68 kg / 155.82 lbs

2 416 Gs

|

10.60 kg / 23.37 lbs

10602 g / 104.0 N

|

63.61 kg / 140.23 lbs

~0 Gs

|

| 3 mm |

70.17 kg / 154.69 lbs

2 408 Gs

|

10.53 kg / 23.20 lbs

10525 g / 103.3 N

|

63.15 kg / 139.22 lbs

~0 Gs

|

| 5 mm |

69.04 kg / 152.21 lbs

2 388 Gs

|

10.36 kg / 22.83 lbs

10356 g / 101.6 N

|

62.14 kg / 136.99 lbs

~0 Gs

|

| 10 mm |

65.68 kg / 144.79 lbs

2 329 Gs

|

9.85 kg / 21.72 lbs

9851 g / 96.6 N

|

59.11 kg / 130.31 lbs

~0 Gs

|

| 20 mm |

57.18 kg / 126.06 lbs

2 173 Gs

|

8.58 kg / 18.91 lbs

8577 g / 84.1 N

|

51.46 kg / 113.45 lbs

~0 Gs

|

| 50 mm |

29.67 kg / 65.40 lbs

1 565 Gs

|

4.45 kg / 9.81 lbs

4450 g / 43.7 N

|

26.70 kg / 58.86 lbs

~0 Gs

|

| 60 mm |

22.60 kg / 49.83 lbs

1 366 Gs

|

3.39 kg / 7.47 lbs

3390 g / 33.3 N

|

20.34 kg / 44.85 lbs

~0 Gs

|

| 70 mm |

16.98 kg / 37.43 lbs

1 184 Gs

|

2.55 kg / 5.61 lbs

2546 g / 25.0 N

|

15.28 kg / 33.68 lbs

~0 Gs

|

| 80 mm |

12.64 kg / 27.87 lbs

1 022 Gs

|

1.90 kg / 4.18 lbs

1896 g / 18.6 N

|

11.38 kg / 25.08 lbs

~0 Gs

|

| 90 mm |

9.38 kg / 20.67 lbs

880 Gs

|

1.41 kg / 3.10 lbs

1406 g / 13.8 N

|

8.44 kg / 18.60 lbs

~0 Gs

|

| 100 mm |

6.95 kg / 15.33 lbs

758 Gs

|

1.04 kg / 2.30 lbs

1043 g / 10.2 N

|

6.26 kg / 13.79 lbs

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MW 100x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 31.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 24.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 19.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 14.5 cm |

| Remote | 50 Gs (5.0 mT) | 13.5 cm |

| Payment card | 400 Gs (40.0 mT) | 5.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.5 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MW 100x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

11.87 km/h

(3.30 m/s)

|

3.20 J | |

| 30 mm |

17.18 km/h

(4.77 m/s)

|

6.71 J | |

| 50 mm |

19.89 km/h

(5.52 m/s)

|

8.99 J | |

| 100 mm |

26.67 km/h

(7.41 m/s)

|

16.17 J |

Table 9: Coating parameters (durability)

MW 100x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 100x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 125 951 Mx | 1259.5 µWb |

| Pc Coefficient | 0.16 | Low (Flat) |

Table 11: Submerged application

MW 100x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 40.86 kg | Standard |

| Water (riverbed) |

46.78 kg

(+5.92 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical surface, the magnet holds just approx. 20-30% of its perpendicular strength.

2. Steel thickness impact

*Thin steel (e.g. computer case) drastically weakens the holding force.

3. Heat tolerance

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.16

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also deals

Advantages as well as disadvantages of rare earth magnets.

Advantages

- Their magnetic field remains stable, and after around ten years it decreases only by ~1% (theoretically),

- They are resistant to demagnetization induced by external magnetic fields,

- In other words, due to the reflective surface of nickel, the element gains visual value,

- Magnetic induction on the working layer of the magnet is exceptional,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Possibility of accurate machining and adapting to atypical applications,

- Versatile presence in innovative solutions – they find application in magnetic memories, brushless drives, precision medical tools, as well as industrial machines.

- Thanks to concentrated force, small magnets offer high operating force, in miniature format,

Limitations

- To avoid cracks upon strong impacts, we recommend using special steel holders. Such a solution secures the magnet and simultaneously improves its durability.

- When exposed to high temperature, neodymium magnets suffer a drop in strength. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation as well as corrosion.

- We suggest a housing - magnetic mechanism, due to difficulties in producing threads inside the magnet and complicated shapes.

- Health risk related to microscopic parts of magnets are risky, if swallowed, which gains importance in the context of child safety. Furthermore, small elements of these devices are able to disrupt the diagnostic process medical in case of swallowing.

- Due to expensive raw materials, their price is relatively high,

Lifting parameters

Maximum lifting force for a neodymium magnet – what it depends on?

- on a block made of structural steel, effectively closing the magnetic flux

- possessing a thickness of at least 10 mm to avoid saturation

- with a surface free of scratches

- with total lack of distance (without impurities)

- during detachment in a direction perpendicular to the plane

- at standard ambient temperature

What influences lifting capacity in practice

- Clearance – the presence of foreign body (paint, dirt, air) acts as an insulator, which reduces power rapidly (even by 50% at 0.5 mm).

- Force direction – remember that the magnet holds strongest perpendicularly. Under shear forces, the capacity drops drastically, often to levels of 20-30% of the maximum value.

- Metal thickness – thin material does not allow full use of the magnet. Magnetic flux passes through the material instead of generating force.

- Material composition – not every steel attracts identically. Alloy additives weaken the interaction with the magnet.

- Surface finish – full contact is possible only on smooth steel. Any scratches and bumps reduce the real contact area, weakening the magnet.

- Thermal environment – heating the magnet causes a temporary drop of force. It is worth remembering the maximum operating temperature for a given model.

Holding force was measured on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, in contrast under parallel forces the holding force is lower. Additionally, even a minimal clearance between the magnet’s surface and the plate reduces the load capacity.

Warnings

Heat warning

Monitor thermal conditions. Heating the magnet above 80 degrees Celsius will ruin its magnetic structure and pulling force.

Shattering risk

Watch out for shards. Magnets can explode upon violent connection, launching sharp fragments into the air. Eye protection is mandatory.

Magnetic interference

GPS units and mobile phones are highly susceptible to magnetic fields. Close proximity with a powerful NdFeB magnet can permanently damage the internal compass in your phone.

This is not a toy

These products are not toys. Accidental ingestion of multiple magnets may result in them pinching intestinal walls, which poses a direct threat to life and requires immediate surgery.

Safe distance

Avoid bringing magnets near a purse, computer, or screen. The magnetism can destroy these devices and erase data from cards.

Do not underestimate power

Before starting, read the rules. Sudden snapping can destroy the magnet or injure your hand. Be predictive.

Hand protection

Large magnets can break fingers instantly. Never put your hand between two attracting surfaces.

Health Danger

Individuals with a pacemaker should keep an absolute distance from magnets. The magnetism can interfere with the operation of the implant.

Do not drill into magnets

Fire hazard: Rare earth powder is highly flammable. Avoid machining magnets in home conditions as this may cause fire.

Allergy Warning

Allergy Notice: The nickel-copper-nickel coating consists of nickel. If redness happens, immediately stop handling magnets and use protective gear.

![BM 650x180x70 [4x M8] - magnetic beam BM 650x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-650x180x70-4x-m8-laj.jpg)