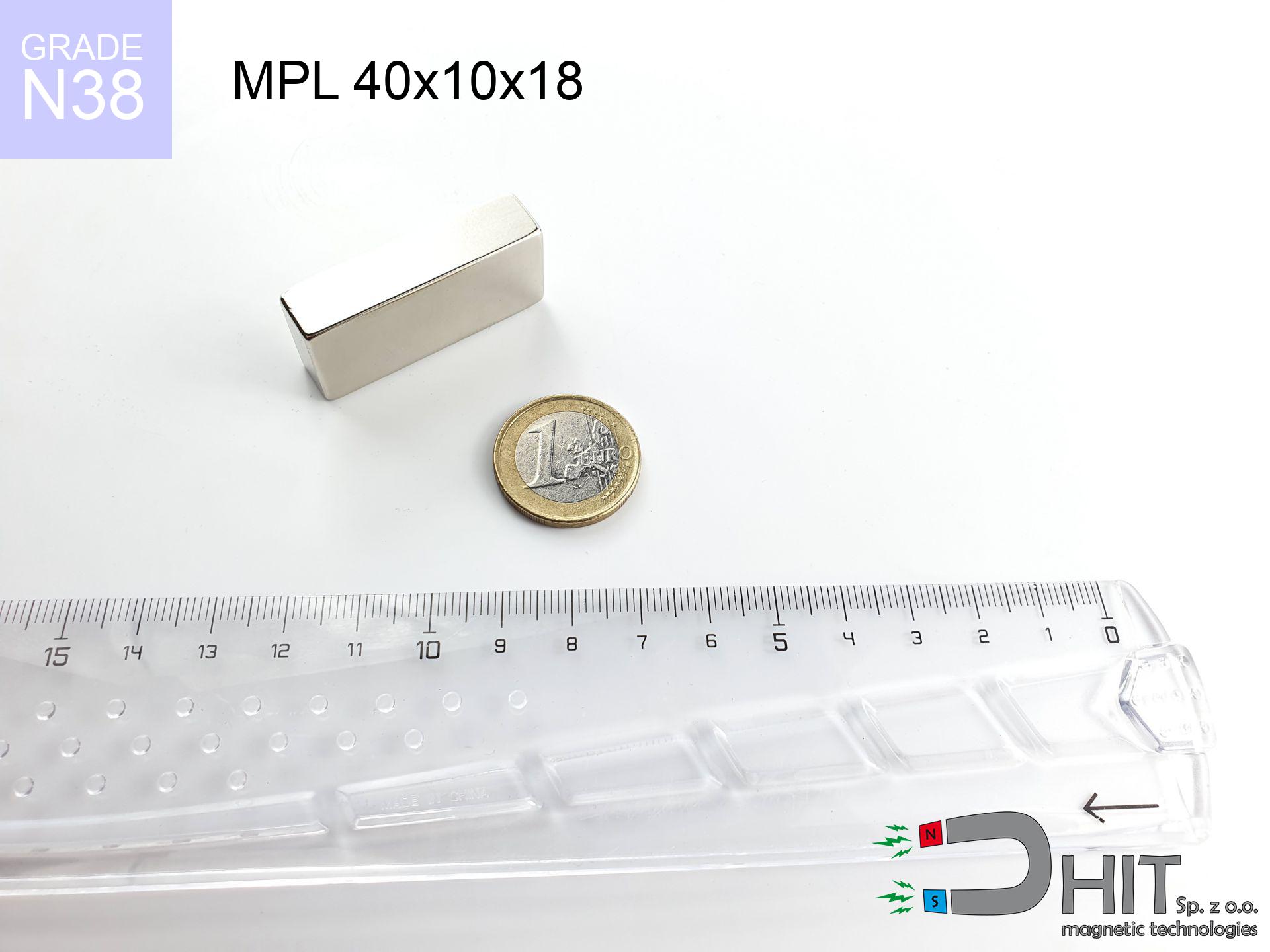

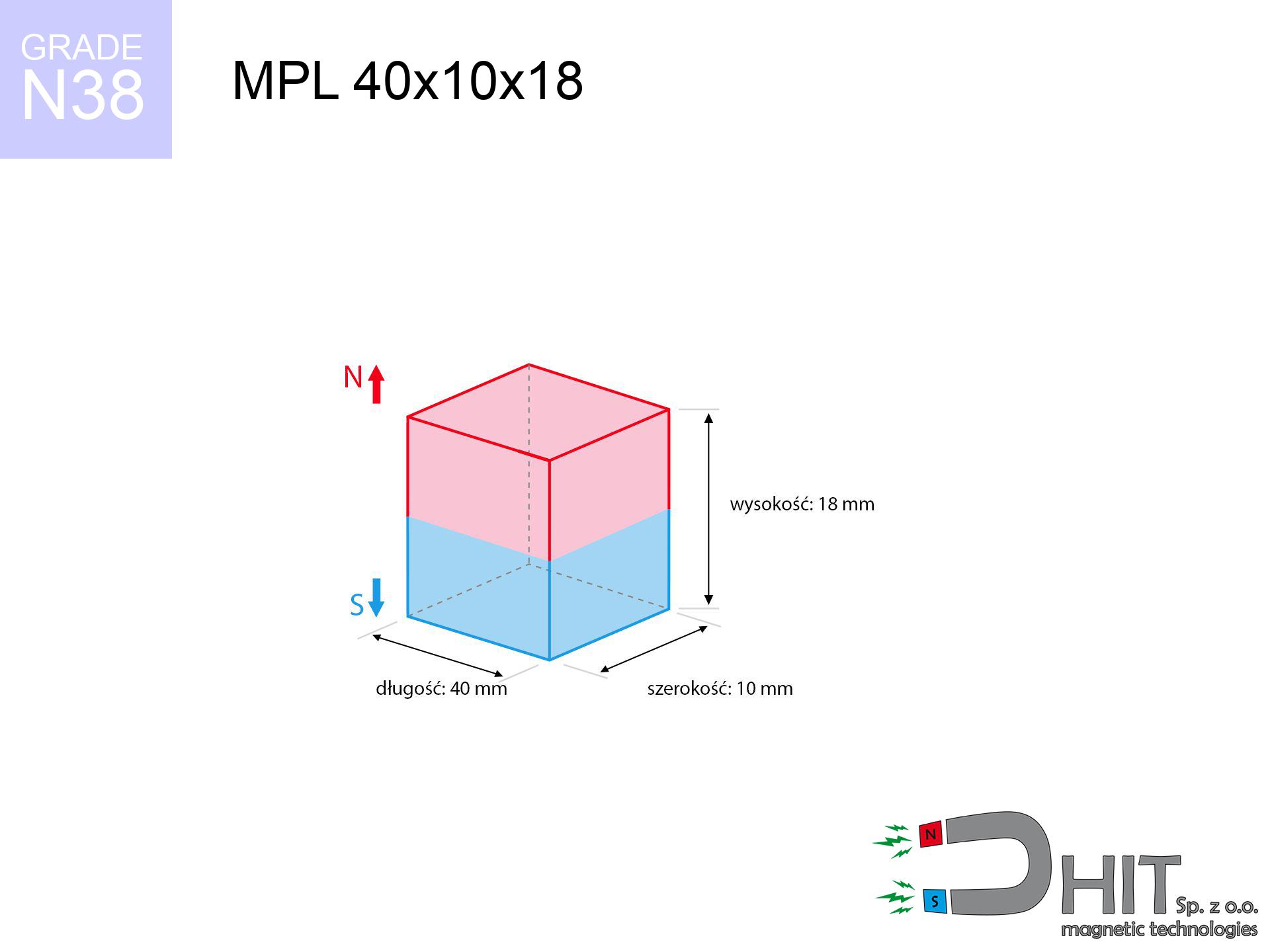

MPL 40x10x18 / N38 - lamellar magnet

lamellar magnet

Catalog no 020149

GTIN/EAN: 5906301811558

length

40 mm [±0,1 mm]

Width

10 mm [±0,1 mm]

Height

18 mm [±0,1 mm]

Weight

54 g

Magnetization Direction

→ diametrical

Load capacity

16.72 kg / 164.01 N

Magnetic Induction

540.48 mT / 5405 Gs

Coating

[NiCuNi] Nickel

18.45 ZŁ with VAT / pcs + price for transport

15.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

otherwise drop us a message using

request form

the contact page.

Lifting power as well as structure of magnets can be reviewed using our

power calculator.

Orders placed before 14:00 will be shipped the same business day.

Product card - MPL 40x10x18 / N38 - lamellar magnet

Specification / characteristics - MPL 40x10x18 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020149 |

| GTIN/EAN | 5906301811558 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 40 mm [±0,1 mm] |

| Width | 10 mm [±0,1 mm] |

| Height | 18 mm [±0,1 mm] |

| Weight | 54 g |

| Magnetization Direction | → diametrical |

| Load capacity ~ ? | 16.72 kg / 164.01 N |

| Magnetic Induction ~ ? | 540.48 mT / 5405 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the magnet - technical parameters

The following data represent the result of a engineering analysis. Values were calculated on models for the material Nd2Fe14B. Operational conditions may differ from theoretical values. Treat these calculations as a supplementary guide for designers.

Table 1: Static force (pull vs distance) - interaction chart

MPL 40x10x18 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5402 Gs

540.2 mT

|

16.72 kg / 36.86 LBS

16720.0 g / 164.0 N

|

critical level |

| 1 mm |

4664 Gs

466.4 mT

|

12.46 kg / 27.48 LBS

12464.6 g / 122.3 N

|

critical level |

| 2 mm |

3970 Gs

397.0 mT

|

9.03 kg / 19.90 LBS

9028.7 g / 88.6 N

|

strong |

| 3 mm |

3362 Gs

336.2 mT

|

6.48 kg / 14.28 LBS

6476.4 g / 63.5 N

|

strong |

| 5 mm |

2432 Gs

243.2 mT

|

3.39 kg / 7.47 LBS

3388.5 g / 33.2 N

|

strong |

| 10 mm |

1220 Gs

122.0 mT

|

0.85 kg / 1.88 LBS

853.2 g / 8.4 N

|

weak grip |

| 15 mm |

703 Gs

70.3 mT

|

0.28 kg / 0.62 LBS

282.9 g / 2.8 N

|

weak grip |

| 20 mm |

440 Gs

44.0 mT

|

0.11 kg / 0.24 LBS

111.1 g / 1.1 N

|

weak grip |

| 30 mm |

203 Gs

20.3 mT

|

0.02 kg / 0.05 LBS

23.6 g / 0.2 N

|

weak grip |

| 50 mm |

64 Gs

6.4 mT

|

0.00 kg / 0.01 LBS

2.4 g / 0.0 N

|

weak grip |

Table 2: Slippage load (vertical surface)

MPL 40x10x18 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

3.34 kg / 7.37 LBS

3344.0 g / 32.8 N

|

| 1 mm | Stal (~0.2) |

2.49 kg / 5.49 LBS

2492.0 g / 24.4 N

|

| 2 mm | Stal (~0.2) |

1.81 kg / 3.98 LBS

1806.0 g / 17.7 N

|

| 3 mm | Stal (~0.2) |

1.30 kg / 2.86 LBS

1296.0 g / 12.7 N

|

| 5 mm | Stal (~0.2) |

0.68 kg / 1.49 LBS

678.0 g / 6.7 N

|

| 10 mm | Stal (~0.2) |

0.17 kg / 0.37 LBS

170.0 g / 1.7 N

|

| 15 mm | Stal (~0.2) |

0.06 kg / 0.12 LBS

56.0 g / 0.5 N

|

| 20 mm | Stal (~0.2) |

0.02 kg / 0.05 LBS

22.0 g / 0.2 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MPL 40x10x18 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

5.02 kg / 11.06 LBS

5016.0 g / 49.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

3.34 kg / 7.37 LBS

3344.0 g / 32.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.67 kg / 3.69 LBS

1672.0 g / 16.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

8.36 kg / 18.43 LBS

8360.0 g / 82.0 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MPL 40x10x18 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.84 kg / 1.84 LBS

836.0 g / 8.2 N

|

| 1 mm |

|

2.09 kg / 4.61 LBS

2090.0 g / 20.5 N

|

| 2 mm |

|

4.18 kg / 9.22 LBS

4180.0 g / 41.0 N

|

| 3 mm |

|

6.27 kg / 13.82 LBS

6270.0 g / 61.5 N

|

| 5 mm |

|

10.45 kg / 23.04 LBS

10450.0 g / 102.5 N

|

| 10 mm |

|

16.72 kg / 36.86 LBS

16720.0 g / 164.0 N

|

| 11 mm |

|

16.72 kg / 36.86 LBS

16720.0 g / 164.0 N

|

| 12 mm |

|

16.72 kg / 36.86 LBS

16720.0 g / 164.0 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MPL 40x10x18 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

16.72 kg / 36.86 LBS

16720.0 g / 164.0 N

|

OK |

| 40 °C | -2.2% |

16.35 kg / 36.05 LBS

16352.2 g / 160.4 N

|

OK |

| 60 °C | -4.4% |

15.98 kg / 35.24 LBS

15984.3 g / 156.8 N

|

OK |

| 80 °C | -6.6% |

15.62 kg / 34.43 LBS

15616.5 g / 153.2 N

|

|

| 100 °C | -28.8% |

11.90 kg / 26.25 LBS

11904.6 g / 116.8 N

|

Table 6: Two magnets (repulsion) - forces in the system

MPL 40x10x18 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

71.96 kg / 158.65 LBS

5 928 Gs

|

10.79 kg / 23.80 LBS

10794 g / 105.9 N

|

N/A |

| 1 mm |

62.49 kg / 137.76 LBS

10 068 Gs

|

9.37 kg / 20.66 LBS

9373 g / 91.9 N

|

56.24 kg / 123.98 LBS

~0 Gs

|

| 2 mm |

53.65 kg / 118.27 LBS

9 328 Gs

|

8.05 kg / 17.74 LBS

8047 g / 78.9 N

|

48.28 kg / 106.44 LBS

~0 Gs

|

| 3 mm |

45.76 kg / 100.88 LBS

8 615 Gs

|

6.86 kg / 15.13 LBS

6864 g / 67.3 N

|

41.18 kg / 90.79 LBS

~0 Gs

|

| 5 mm |

32.92 kg / 72.58 LBS

7 308 Gs

|

4.94 kg / 10.89 LBS

4938 g / 48.4 N

|

29.63 kg / 65.32 LBS

~0 Gs

|

| 10 mm |

14.58 kg / 32.15 LBS

4 864 Gs

|

2.19 kg / 4.82 LBS

2188 g / 21.5 N

|

13.13 kg / 28.94 LBS

~0 Gs

|

| 20 mm |

3.67 kg / 8.10 LBS

2 441 Gs

|

0.55 kg / 1.21 LBS

551 g / 5.4 N

|

3.30 kg / 7.29 LBS

~0 Gs

|

| 50 mm |

0.21 kg / 0.46 LBS

585 Gs

|

0.03 kg / 0.07 LBS

32 g / 0.3 N

|

0.19 kg / 0.42 LBS

~0 Gs

|

| 60 mm |

0.10 kg / 0.22 LBS

406 Gs

|

0.02 kg / 0.03 LBS

15 g / 0.1 N

|

0.09 kg / 0.20 LBS

~0 Gs

|

| 70 mm |

0.05 kg / 0.12 LBS

293 Gs

|

0.01 kg / 0.02 LBS

8 g / 0.1 N

|

0.05 kg / 0.10 LBS

~0 Gs

|

| 80 mm |

0.03 kg / 0.06 LBS

217 Gs

|

0.00 kg / 0.01 LBS

4 g / 0.0 N

|

0.03 kg / 0.06 LBS

~0 Gs

|

| 90 mm |

0.02 kg / 0.04 LBS

165 Gs

|

0.00 kg / 0.01 LBS

3 g / 0.0 N

|

0.02 kg / 0.03 LBS

~0 Gs

|

| 100 mm |

0.01 kg / 0.02 LBS

128 Gs

|

0.00 kg / 0.00 LBS

2 g / 0.0 N

|

0.01 kg / 0.02 LBS

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MPL 40x10x18 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 13.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 10.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 8.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 6.5 cm |

| Remote | 50 Gs (5.0 mT) | 6.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Impact energy (kinetic energy) - collision effects

MPL 40x10x18 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

18.30 km/h

(5.08 m/s)

|

0.70 J | |

| 30 mm |

30.76 km/h

(8.55 m/s)

|

1.97 J | |

| 50 mm |

39.69 km/h

(11.02 m/s)

|

3.28 J | |

| 100 mm |

56.12 km/h

(15.59 m/s)

|

6.56 J |

Table 9: Corrosion resistance

MPL 40x10x18 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 40x10x18 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 21 285 Mx | 212.9 µWb |

| Pc Coefficient | 0.79 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MPL 40x10x18 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 16.72 kg | Standard |

| Water (riverbed) |

19.14 kg

(+2.42 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical wall, the magnet holds only ~20% of its nominal pull.

2. Steel saturation

*Thin metal sheet (e.g. computer case) significantly weakens the holding force.

3. Power loss vs temp

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.79

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Pros and cons of neodymium magnets.

Advantages

- Their magnetic field is maintained, and after around 10 years it decreases only by ~1% (theoretically),

- They are noted for resistance to demagnetization induced by external field influence,

- By covering with a smooth layer of silver, the element gains an nice look,

- Magnetic induction on the surface of the magnet is very high,

- Thanks to resistance to high temperature, they are able to function (depending on the shape) even at temperatures up to 230°C and higher...

- Possibility of exact machining and optimizing to atypical needs,

- Huge importance in modern industrial fields – they are commonly used in data components, electromotive mechanisms, advanced medical instruments, and multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer high power in small dimensions, which allows their use in compact constructions

Cons

- Brittleness is one of their disadvantages. Upon strong impact they can fracture. We recommend keeping them in a strong case, which not only protects them against impacts but also increases their durability

- When exposed to high temperature, neodymium magnets suffer a drop in strength. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation as well as corrosion.

- We suggest a housing - magnetic mount, due to difficulties in creating threads inside the magnet and complicated forms.

- Health risk to health – tiny shards of magnets pose a threat, if swallowed, which becomes key in the context of child health protection. It is also worth noting that small elements of these devices can disrupt the diagnostic process medical when they are in the body.

- Due to neodymium price, their price is relatively high,

Lifting parameters

Optimal lifting capacity of a neodymium magnet – what contributes to it?

- on a plate made of structural steel, effectively closing the magnetic flux

- whose transverse dimension equals approx. 10 mm

- characterized by smoothness

- without the slightest insulating layer between the magnet and steel

- under axial force vector (90-degree angle)

- in temp. approx. 20°C

What influences lifting capacity in practice

- Gap between magnet and steel – every millimeter of separation (caused e.g. by varnish or dirt) diminishes the pulling force, often by half at just 0.5 mm.

- Loading method – catalog parameter refers to pulling vertically. When attempting to slide, the magnet holds significantly lower power (typically approx. 20-30% of nominal force).

- Base massiveness – insufficiently thick plate causes magnetic saturation, causing part of the flux to be wasted into the air.

- Material composition – different alloys attracts identically. High carbon content worsen the interaction with the magnet.

- Surface quality – the smoother and more polished the surface, the larger the contact zone and stronger the hold. Roughness creates an air distance.

- Thermal factor – high temperature reduces pulling force. Too high temperature can permanently damage the magnet.

Holding force was measured on the plate surface of 20 mm thickness, when a perpendicular force was applied, whereas under shearing force the holding force is lower. In addition, even a slight gap between the magnet’s surface and the plate reduces the load capacity.

Warnings

Impact on smartphones

Remember: rare earth magnets generate a field that interferes with sensitive sensors. Maintain a separation from your phone, device, and GPS.

Fire warning

Powder created during cutting of magnets is self-igniting. Do not drill into magnets without proper cooling and knowledge.

Do not give to children

Strictly keep magnets away from children. Choking hazard is significant, and the effects of magnets clamping inside the body are very dangerous.

Crushing risk

Protect your hands. Two powerful magnets will snap together instantly with a force of massive weight, destroying anything in their path. Be careful!

Powerful field

Handle with care. Neodymium magnets attract from a long distance and snap with massive power, often quicker than you can react.

Life threat

Life threat: Strong magnets can deactivate heart devices and defibrillators. Stay away if you have electronic implants.

Skin irritation risks

Medical facts indicate that the nickel plating (standard magnet coating) is a strong allergen. If your skin reacts to metals, prevent touching magnets with bare hands or select coated magnets.

Data carriers

Very strong magnetic fields can destroy records on payment cards, hard drives, and storage devices. Maintain a gap of at least 10 cm.

Heat sensitivity

Standard neodymium magnets (N-type) lose magnetization when the temperature goes above 80°C. Damage is permanent.

Material brittleness

Protect your eyes. Magnets can fracture upon violent connection, ejecting sharp fragments into the air. Eye protection is mandatory.

![SM 25x225 [2xM8] / N42 - magnetic separator SM 25x225 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x225-2xm8-tix.jpg)