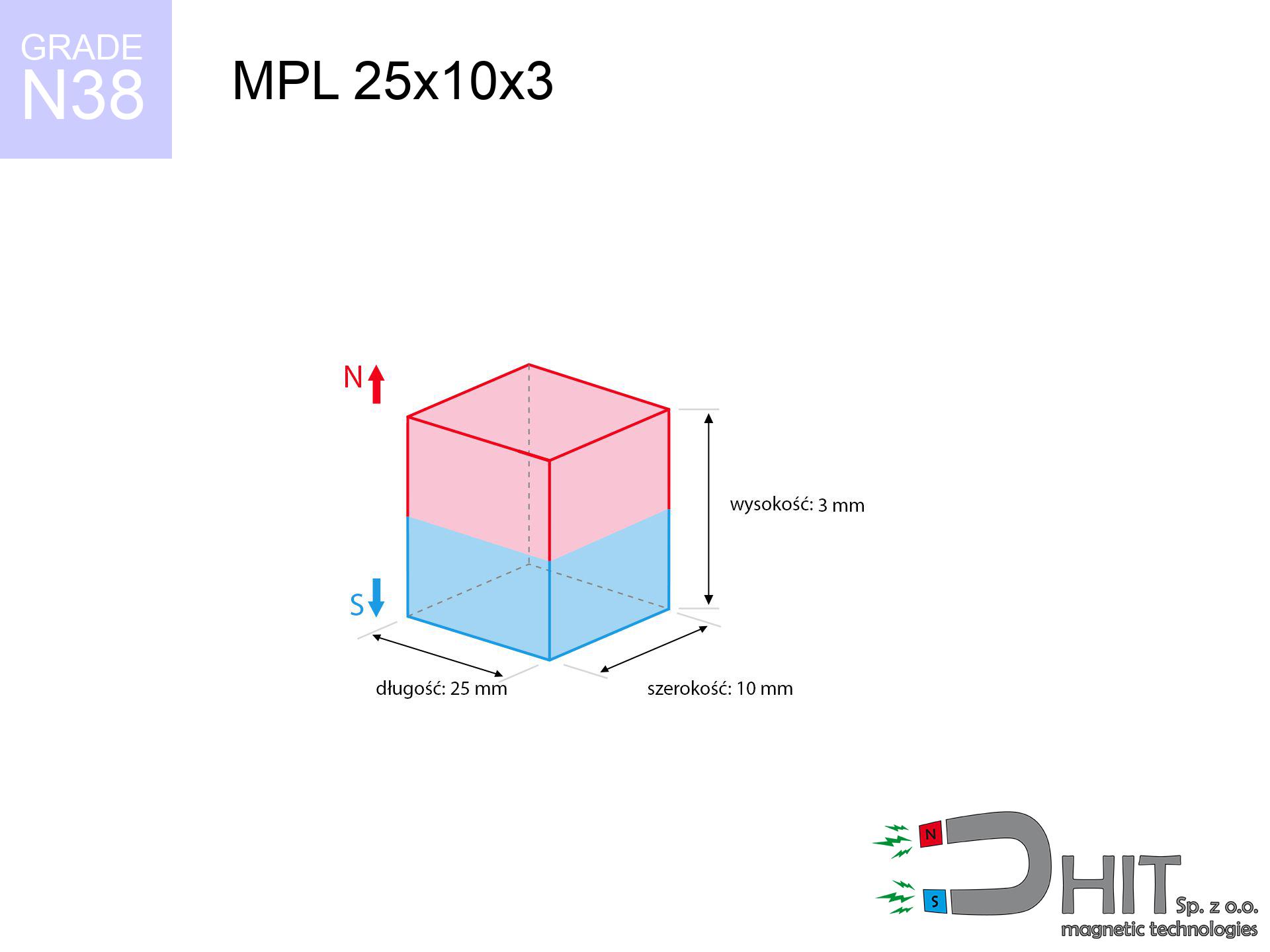

MPL 25x10x3 / N38 - lamellar magnet

lamellar magnet

Catalog no 020387

GTIN/EAN: 5906301811862

length

25 mm [±0,1 mm]

Width

10 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

5.63 g

Magnetization Direction

↑ axial

Load capacity

4.14 kg / 40.56 N

Magnetic Induction

230.69 mT / 2307 Gs

Coating

[NiCuNi] Nickel

3.57 ZŁ with VAT / pcs + price for transport

2.90 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

alternatively send us a note via

request form

the contact page.

Specifications along with form of a magnet can be verified using our

force calculator.

Order by 14:00 and we’ll ship today!

Technical details - MPL 25x10x3 / N38 - lamellar magnet

Specification / characteristics - MPL 25x10x3 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020387 |

| GTIN/EAN | 5906301811862 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 25 mm [±0,1 mm] |

| Width | 10 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 5.63 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 4.14 kg / 40.56 N |

| Magnetic Induction ~ ? | 230.69 mT / 2307 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the magnet - data

Presented data are the result of a mathematical simulation. Results are based on algorithms for the class Nd2Fe14B. Actual parameters may deviate from the simulation results. Please consider these calculations as a supplementary guide during assembly planning.

Table 1: Static pull force (force vs distance) - characteristics

MPL 25x10x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2306 Gs

230.6 mT

|

4.14 kg / 9.13 LBS

4140.0 g / 40.6 N

|

strong |

| 1 mm |

2050 Gs

205.0 mT

|

3.27 kg / 7.21 LBS

3272.4 g / 32.1 N

|

strong |

| 2 mm |

1752 Gs

175.2 mT

|

2.39 kg / 5.27 LBS

2388.9 g / 23.4 N

|

strong |

| 3 mm |

1463 Gs

146.3 mT

|

1.67 kg / 3.68 LBS

1667.1 g / 16.4 N

|

safe |

| 5 mm |

1000 Gs

100.0 mT

|

0.78 kg / 1.72 LBS

779.2 g / 7.6 N

|

safe |

| 10 mm |

416 Gs

41.6 mT

|

0.13 kg / 0.30 LBS

134.4 g / 1.3 N

|

safe |

| 15 mm |

200 Gs

20.0 mT

|

0.03 kg / 0.07 LBS

31.0 g / 0.3 N

|

safe |

| 20 mm |

108 Gs

10.8 mT

|

0.01 kg / 0.02 LBS

9.0 g / 0.1 N

|

safe |

| 30 mm |

40 Gs

4.0 mT

|

0.00 kg / 0.00 LBS

1.3 g / 0.0 N

|

safe |

| 50 mm |

10 Gs

1.0 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

safe |

Table 2: Vertical force (wall)

MPL 25x10x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.83 kg / 1.83 LBS

828.0 g / 8.1 N

|

| 1 mm | Stal (~0.2) |

0.65 kg / 1.44 LBS

654.0 g / 6.4 N

|

| 2 mm | Stal (~0.2) |

0.48 kg / 1.05 LBS

478.0 g / 4.7 N

|

| 3 mm | Stal (~0.2) |

0.33 kg / 0.74 LBS

334.0 g / 3.3 N

|

| 5 mm | Stal (~0.2) |

0.16 kg / 0.34 LBS

156.0 g / 1.5 N

|

| 10 mm | Stal (~0.2) |

0.03 kg / 0.06 LBS

26.0 g / 0.3 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.01 LBS

6.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MPL 25x10x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.24 kg / 2.74 LBS

1242.0 g / 12.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.83 kg / 1.83 LBS

828.0 g / 8.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.41 kg / 0.91 LBS

414.0 g / 4.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.07 kg / 4.56 LBS

2070.0 g / 20.3 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MPL 25x10x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.41 kg / 0.91 LBS

414.0 g / 4.1 N

|

| 1 mm |

|

1.04 kg / 2.28 LBS

1035.0 g / 10.2 N

|

| 2 mm |

|

2.07 kg / 4.56 LBS

2070.0 g / 20.3 N

|

| 3 mm |

|

3.10 kg / 6.85 LBS

3105.0 g / 30.5 N

|

| 5 mm |

|

4.14 kg / 9.13 LBS

4140.0 g / 40.6 N

|

| 10 mm |

|

4.14 kg / 9.13 LBS

4140.0 g / 40.6 N

|

| 11 mm |

|

4.14 kg / 9.13 LBS

4140.0 g / 40.6 N

|

| 12 mm |

|

4.14 kg / 9.13 LBS

4140.0 g / 40.6 N

|

Table 5: Thermal stability (stability) - thermal limit

MPL 25x10x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

4.14 kg / 9.13 LBS

4140.0 g / 40.6 N

|

OK |

| 40 °C | -2.2% |

4.05 kg / 8.93 LBS

4048.9 g / 39.7 N

|

OK |

| 60 °C | -4.4% |

3.96 kg / 8.73 LBS

3957.8 g / 38.8 N

|

|

| 80 °C | -6.6% |

3.87 kg / 8.52 LBS

3866.8 g / 37.9 N

|

|

| 100 °C | -28.8% |

2.95 kg / 6.50 LBS

2947.7 g / 28.9 N

|

Table 6: Two magnets (repulsion) - field range

MPL 25x10x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

8.20 kg / 18.07 LBS

3 767 Gs

|

1.23 kg / 2.71 LBS

1230 g / 12.1 N

|

N/A |

| 1 mm |

7.38 kg / 16.27 LBS

4 377 Gs

|

1.11 kg / 2.44 LBS

1107 g / 10.9 N

|

6.64 kg / 14.65 LBS

~0 Gs

|

| 2 mm |

6.48 kg / 14.28 LBS

4 101 Gs

|

0.97 kg / 2.14 LBS

972 g / 9.5 N

|

5.83 kg / 12.86 LBS

~0 Gs

|

| 3 mm |

5.58 kg / 12.30 LBS

3 805 Gs

|

0.84 kg / 1.84 LBS

837 g / 8.2 N

|

5.02 kg / 11.07 LBS

~0 Gs

|

| 5 mm |

3.97 kg / 8.74 LBS

3 208 Gs

|

0.59 kg / 1.31 LBS

595 g / 5.8 N

|

3.57 kg / 7.87 LBS

~0 Gs

|

| 10 mm |

1.54 kg / 3.40 LBS

2 001 Gs

|

0.23 kg / 0.51 LBS

231 g / 2.3 N

|

1.39 kg / 3.06 LBS

~0 Gs

|

| 20 mm |

0.27 kg / 0.59 LBS

831 Gs

|

0.04 kg / 0.09 LBS

40 g / 0.4 N

|

0.24 kg / 0.53 LBS

~0 Gs

|

| 50 mm |

0.01 kg / 0.01 LBS

127 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.01 LBS

80 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

54 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

38 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

27 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

20 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Safety (HSE) (electronics) - precautionary measures

MPL 25x10x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.5 cm |

| Car key | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (cracking risk) - warning

MPL 25x10x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

27.90 km/h

(7.75 m/s)

|

0.17 J | |

| 30 mm |

47.38 km/h

(13.16 m/s)

|

0.49 J | |

| 50 mm |

61.15 km/h

(16.99 m/s)

|

0.81 J | |

| 100 mm |

86.48 km/h

(24.02 m/s)

|

1.62 J |

Table 9: Coating parameters (durability)

MPL 25x10x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MPL 25x10x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 5 928 Mx | 59.3 µWb |

| Pc Coefficient | 0.25 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 25x10x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 4.14 kg | Standard |

| Water (riverbed) |

4.74 kg

(+0.60 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical surface, the magnet retains merely ~20% of its nominal pull.

2. Plate thickness effect

*Thin metal sheet (e.g. 0.5mm PC case) significantly limits the holding force.

3. Temperature resistance

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.25

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also products

Pros and cons of Nd2Fe14B magnets.

Benefits

- They retain full power for almost 10 years – the drop is just ~1% (according to analyses),

- Neodymium magnets prove to be extremely resistant to demagnetization caused by external magnetic fields,

- The use of an shiny coating of noble metals (nickel, gold, silver) causes the element to be more visually attractive,

- The surface of neodymium magnets generates a intense magnetic field – this is a distinguishing feature,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Possibility of individual shaping and adjusting to atypical conditions,

- Versatile presence in future technologies – they serve a role in mass storage devices, brushless drives, diagnostic systems, also complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer high power in compact dimensions, which allows their use in compact constructions

Disadvantages

- Brittleness is one of their disadvantages. Upon strong impact they can break. We recommend keeping them in a special holder, which not only protects them against impacts but also increases their durability

- We warn that neodymium magnets can reduce their strength at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- They rust in a humid environment. For use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- We recommend a housing - magnetic holder, due to difficulties in producing nuts inside the magnet and complex forms.

- Health risk resulting from small fragments of magnets pose a threat, if swallowed, which gains importance in the aspect of protecting the youngest. It is also worth noting that small elements of these products are able to be problematic in diagnostics medical after entering the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Lifting parameters

Highest magnetic holding force – what affects it?

- using a sheet made of low-carbon steel, acting as a magnetic yoke

- possessing a thickness of minimum 10 mm to ensure full flux closure

- with an ideally smooth contact surface

- with direct contact (no impurities)

- under perpendicular force vector (90-degree angle)

- at temperature approx. 20 degrees Celsius

Lifting capacity in real conditions – factors

- Distance (between the magnet and the plate), since even a very small distance (e.g. 0.5 mm) leads to a reduction in lifting capacity by up to 50% (this also applies to varnish, corrosion or dirt).

- Force direction – catalog parameter refers to pulling vertically. When attempting to slide, the magnet exhibits much less (often approx. 20-30% of maximum force).

- Steel thickness – insufficiently thick plate does not accept the full field, causing part of the power to be wasted to the other side.

- Steel grade – ideal substrate is high-permeability steel. Hardened steels may attract less.

- Plate texture – ground elements ensure maximum contact, which improves force. Uneven metal weaken the grip.

- Heat – neodymium magnets have a negative temperature coefficient. When it is hot they lose power, and at low temperatures they can be stronger (up to a certain limit).

Holding force was measured on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, whereas under attempts to slide the magnet the holding force is lower. Moreover, even a minimal clearance between the magnet’s surface and the plate reduces the load capacity.

Precautions when working with neodymium magnets

Phone sensors

GPS units and mobile phones are extremely sensitive to magnetism. Direct contact with a strong magnet can decalibrate the sensors in your phone.

Danger to the youngest

Only for adults. Small elements can be swallowed, causing intestinal necrosis. Keep away from kids and pets.

Material brittleness

NdFeB magnets are sintered ceramics, which means they are prone to chipping. Collision of two magnets will cause them cracking into shards.

Safe operation

Use magnets consciously. Their huge power can shock even professionals. Be vigilant and do not underestimate their power.

Pinching danger

Danger of trauma: The attraction force is so immense that it can cause blood blisters, crushing, and even bone fractures. Protective gloves are recommended.

Avoid contact if allergic

It is widely known that nickel (standard magnet coating) is a strong allergen. If you have an allergy, avoid direct skin contact or opt for coated magnets.

Dust is flammable

Dust generated during grinding of magnets is self-igniting. Avoid drilling into magnets unless you are an expert.

Implant safety

For implant holders: Strong magnetic fields affect electronics. Keep at least 30 cm distance or request help to handle the magnets.

Heat warning

Watch the temperature. Heating the magnet above 80 degrees Celsius will ruin its magnetic structure and pulling force.

Protect data

Avoid bringing magnets close to a purse, laptop, or screen. The magnetic field can permanently damage these devices and erase data from cards.

![SM 32x400 [2xM8] / N42 - magnetic separator SM 32x400 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x400-2xm8-tep.jpg)