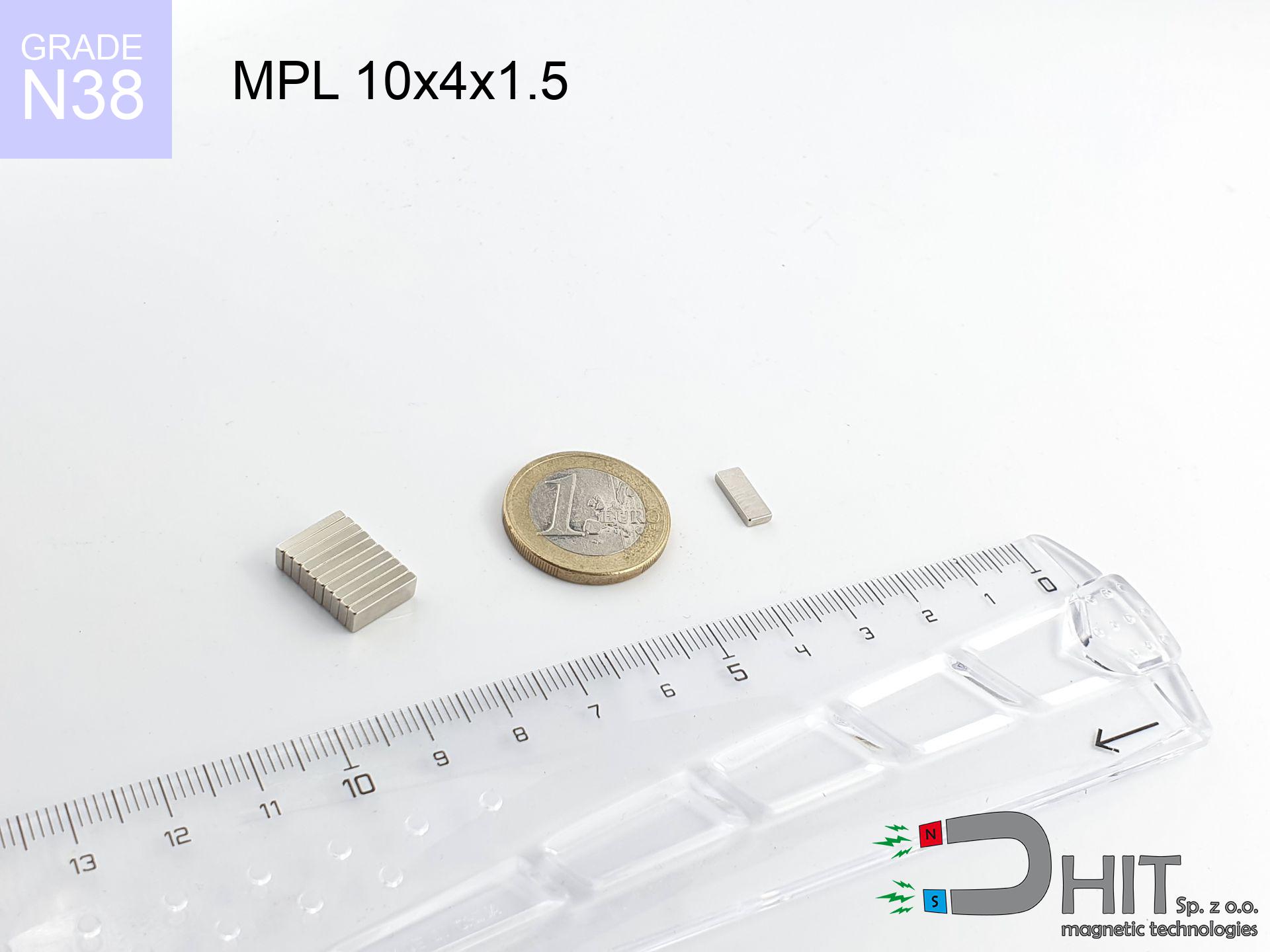

MPL 10x4x1.5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020113

GTIN/EAN: 5906301811190

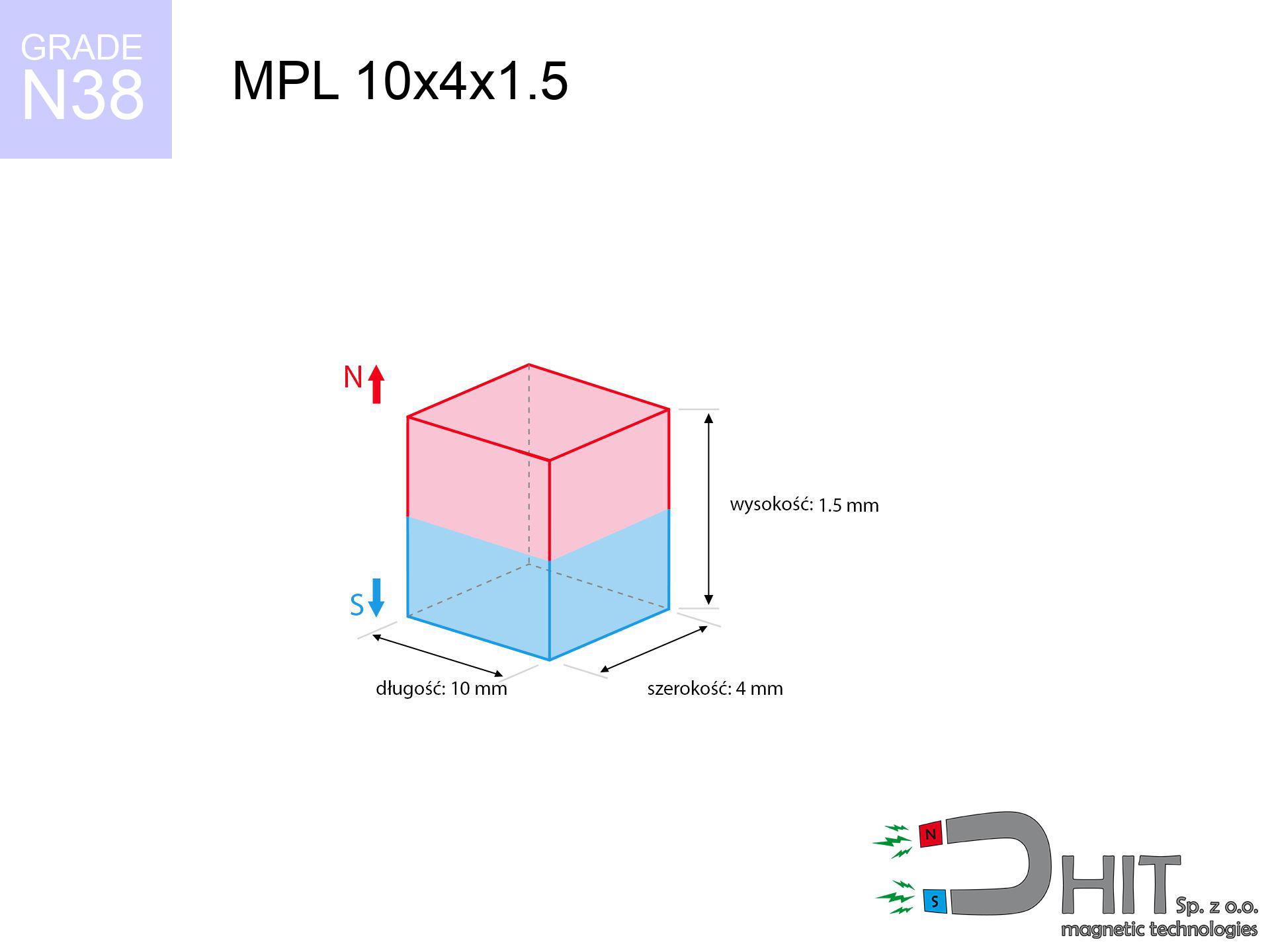

length

10 mm [±0,1 mm]

Width

4 mm [±0,1 mm]

Height

1.5 mm [±0,1 mm]

Weight

0.45 g

Magnetization Direction

↑ axial

Load capacity

0.88 kg / 8.65 N

Magnetic Induction

274.96 mT / 2750 Gs

Coating

[NiCuNi] Nickel

0.246 ZŁ with VAT / pcs + price for transport

0.200 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

or get in touch by means of

contact form

through our site.

Specifications and structure of a magnet can be reviewed using our

power calculator.

Order by 14:00 and we’ll ship today!

Physical properties - MPL 10x4x1.5 / N38 - lamellar magnet

Specification / characteristics - MPL 10x4x1.5 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020113 |

| GTIN/EAN | 5906301811190 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 10 mm [±0,1 mm] |

| Width | 4 mm [±0,1 mm] |

| Height | 1.5 mm [±0,1 mm] |

| Weight | 0.45 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.88 kg / 8.65 N |

| Magnetic Induction ~ ? | 274.96 mT / 2750 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the magnet - report

Presented information constitute the outcome of a mathematical calculation. Values were calculated on models for the class Nd2Fe14B. Actual performance might slightly deviate from the simulation results. Use these data as a reference point for designers.

Table 1: Static pull force (pull vs distance) - power drop

MPL 10x4x1.5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2747 Gs

274.7 mT

|

0.88 kg / 1.94 pounds

880.0 g / 8.6 N

|

weak grip |

| 1 mm |

1882 Gs

188.2 mT

|

0.41 kg / 0.91 pounds

413.1 g / 4.1 N

|

weak grip |

| 2 mm |

1175 Gs

117.5 mT

|

0.16 kg / 0.35 pounds

161.0 g / 1.6 N

|

weak grip |

| 3 mm |

746 Gs

74.6 mT

|

0.06 kg / 0.14 pounds

64.9 g / 0.6 N

|

weak grip |

| 5 mm |

337 Gs

33.7 mT

|

0.01 kg / 0.03 pounds

13.3 g / 0.1 N

|

weak grip |

| 10 mm |

77 Gs

7.7 mT

|

0.00 kg / 0.00 pounds

0.7 g / 0.0 N

|

weak grip |

| 15 mm |

27 Gs

2.7 mT

|

0.00 kg / 0.00 pounds

0.1 g / 0.0 N

|

weak grip |

| 20 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

weak grip |

| 30 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

weak grip |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

weak grip |

Table 2: Sliding hold (wall)

MPL 10x4x1.5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.18 kg / 0.39 pounds

176.0 g / 1.7 N

|

| 1 mm | Stal (~0.2) |

0.08 kg / 0.18 pounds

82.0 g / 0.8 N

|

| 2 mm | Stal (~0.2) |

0.03 kg / 0.07 pounds

32.0 g / 0.3 N

|

| 3 mm | Stal (~0.2) |

0.01 kg / 0.03 pounds

12.0 g / 0.1 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MPL 10x4x1.5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.26 kg / 0.58 pounds

264.0 g / 2.6 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.18 kg / 0.39 pounds

176.0 g / 1.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.09 kg / 0.19 pounds

88.0 g / 0.9 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.44 kg / 0.97 pounds

440.0 g / 4.3 N

|

Table 4: Steel thickness (substrate influence) - power losses

MPL 10x4x1.5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.09 kg / 0.19 pounds

88.0 g / 0.9 N

|

| 1 mm |

|

0.22 kg / 0.49 pounds

220.0 g / 2.2 N

|

| 2 mm |

|

0.44 kg / 0.97 pounds

440.0 g / 4.3 N

|

| 3 mm |

|

0.66 kg / 1.46 pounds

660.0 g / 6.5 N

|

| 5 mm |

|

0.88 kg / 1.94 pounds

880.0 g / 8.6 N

|

| 10 mm |

|

0.88 kg / 1.94 pounds

880.0 g / 8.6 N

|

| 11 mm |

|

0.88 kg / 1.94 pounds

880.0 g / 8.6 N

|

| 12 mm |

|

0.88 kg / 1.94 pounds

880.0 g / 8.6 N

|

Table 5: Thermal stability (stability) - thermal limit

MPL 10x4x1.5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.88 kg / 1.94 pounds

880.0 g / 8.6 N

|

OK |

| 40 °C | -2.2% |

0.86 kg / 1.90 pounds

860.6 g / 8.4 N

|

OK |

| 60 °C | -4.4% |

0.84 kg / 1.85 pounds

841.3 g / 8.3 N

|

|

| 80 °C | -6.6% |

0.82 kg / 1.81 pounds

821.9 g / 8.1 N

|

|

| 100 °C | -28.8% |

0.63 kg / 1.38 pounds

626.6 g / 6.1 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MPL 10x4x1.5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

1.86 kg / 4.10 pounds

4 229 Gs

|

0.28 kg / 0.62 pounds

279 g / 2.7 N

|

N/A |

| 1 mm |

1.34 kg / 2.95 pounds

4 661 Gs

|

0.20 kg / 0.44 pounds

201 g / 2.0 N

|

1.21 kg / 2.66 pounds

~0 Gs

|

| 2 mm |

0.87 kg / 1.93 pounds

3 764 Gs

|

0.13 kg / 0.29 pounds

131 g / 1.3 N

|

0.79 kg / 1.73 pounds

~0 Gs

|

| 3 mm |

0.55 kg / 1.21 pounds

2 978 Gs

|

0.08 kg / 0.18 pounds

82 g / 0.8 N

|

0.49 kg / 1.09 pounds

~0 Gs

|

| 5 mm |

0.21 kg / 0.47 pounds

1 864 Gs

|

0.03 kg / 0.07 pounds

32 g / 0.3 N

|

0.19 kg / 0.43 pounds

~0 Gs

|

| 10 mm |

0.03 kg / 0.06 pounds

675 Gs

|

0.00 kg / 0.01 pounds

4 g / 0.0 N

|

0.03 kg / 0.06 pounds

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 pounds

154 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

13 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

8 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

5 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

3 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

2 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

2 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MPL 10x4x1.5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 1.5 cm |

| Car key | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 0.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Collisions (kinetic energy) - collision effects

MPL 10x4x1.5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

44.62 km/h

(12.39 m/s)

|

0.03 J | |

| 30 mm |

77.25 km/h

(21.46 m/s)

|

0.10 J | |

| 50 mm |

99.72 km/h

(27.70 m/s)

|

0.17 J | |

| 100 mm |

141.03 km/h

(39.18 m/s)

|

0.35 J |

Table 9: Anti-corrosion coating durability

MPL 10x4x1.5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 10x4x1.5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 104 Mx | 11.0 µWb |

| Pc Coefficient | 0.30 | Low (Flat) |

Table 11: Submerged application

MPL 10x4x1.5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.88 kg | Standard |

| Water (riverbed) |

1.01 kg

(+0.13 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Caution: On a vertical surface, the magnet retains just a fraction of its nominal pull.

2. Plate thickness effect

*Thin steel (e.g. computer case) drastically reduces the holding force.

3. Thermal stability

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.30

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Advantages as well as disadvantages of neodymium magnets.

Pros

- They do not lose power, even during around 10 years – the decrease in power is only ~1% (according to tests),

- They feature excellent resistance to magnetic field loss when exposed to opposing magnetic fields,

- Thanks to the reflective finish, the coating of nickel, gold, or silver gives an modern appearance,

- They show high magnetic induction at the operating surface, which increases their power,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and are able to act (depending on the shape) even at a temperature of 230°C or more...

- Possibility of accurate shaping and adapting to concrete applications,

- Wide application in modern technologies – they are utilized in magnetic memories, drive modules, diagnostic systems, and technologically advanced constructions.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which makes them useful in compact constructions

Disadvantages

- At very strong impacts they can break, therefore we advise placing them in steel cases. A metal housing provides additional protection against damage and increases the magnet's durability.

- We warn that neodymium magnets can reduce their strength at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- They oxidize in a humid environment - during use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- Limited possibility of producing nuts in the magnet and complex forms - recommended is casing - magnet mounting.

- Possible danger resulting from small fragments of magnets are risky, in case of ingestion, which is particularly important in the aspect of protecting the youngest. Furthermore, small components of these magnets are able to be problematic in diagnostics medical after entering the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Lifting parameters

Detachment force of the magnet in optimal conditions – what contributes to it?

- using a base made of mild steel, serving as a circuit closing element

- whose thickness is min. 10 mm

- characterized by smoothness

- with zero gap (no paint)

- under vertical application of breakaway force (90-degree angle)

- at ambient temperature approx. 20 degrees Celsius

What influences lifting capacity in practice

- Distance – existence of foreign body (paint, tape, air) interrupts the magnetic circuit, which reduces capacity steeply (even by 50% at 0.5 mm).

- Angle of force application – maximum parameter is available only during perpendicular pulling. The resistance to sliding of the magnet along the surface is usually many times smaller (approx. 1/5 of the lifting capacity).

- Steel thickness – too thin sheet does not close the flux, causing part of the flux to be lost to the other side.

- Chemical composition of the base – low-carbon steel attracts best. Alloy admixtures lower magnetic properties and holding force.

- Smoothness – ideal contact is possible only on polished steel. Any scratches and bumps reduce the real contact area, reducing force.

- Thermal environment – temperature increase results in weakening of force. It is worth remembering the thermal limit for a given model.

Holding force was checked on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, whereas under parallel forces the lifting capacity is smaller. Additionally, even a small distance between the magnet and the plate lowers the lifting capacity.

H&S for magnets

Fragile material

Neodymium magnets are sintered ceramics, meaning they are fragile like glass. Clashing of two magnets leads to them breaking into shards.

Safe operation

Handle with care. Neodymium magnets act from a long distance and snap with huge force, often faster than you can react.

Keep away from children

Neodymium magnets are not toys. Eating multiple magnets can lead to them pinching intestinal walls, which constitutes a direct threat to life and requires urgent medical intervention.

Do not overheat magnets

Standard neodymium magnets (N-type) lose power when the temperature surpasses 80°C. The loss of strength is permanent.

Bodily injuries

Mind your fingers. Two powerful magnets will join immediately with a force of several hundred kilograms, crushing anything in their path. Exercise extreme caution!

ICD Warning

For implant holders: Strong magnetic fields affect electronics. Maintain at least 30 cm distance or ask another person to handle the magnets.

Flammability

Fire warning: Neodymium dust is explosive. Avoid machining magnets in home conditions as this may cause fire.

Cards and drives

Very strong magnetic fields can corrupt files on payment cards, hard drives, and storage devices. Maintain a gap of min. 10 cm.

Precision electronics

GPS units and smartphones are highly susceptible to magnetic fields. Direct contact with a strong magnet can ruin the internal compass in your phone.

Metal Allergy

Warning for allergy sufferers: The nickel-copper-nickel coating consists of nickel. If skin irritation happens, immediately stop working with magnets and use protective gear.

![UMGGW 34x8 [M4] GW / N38 - magnetic holder rubber internal thread UMGGW 34x8 [M4] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-34x8-m4-gw-kek.jpg)