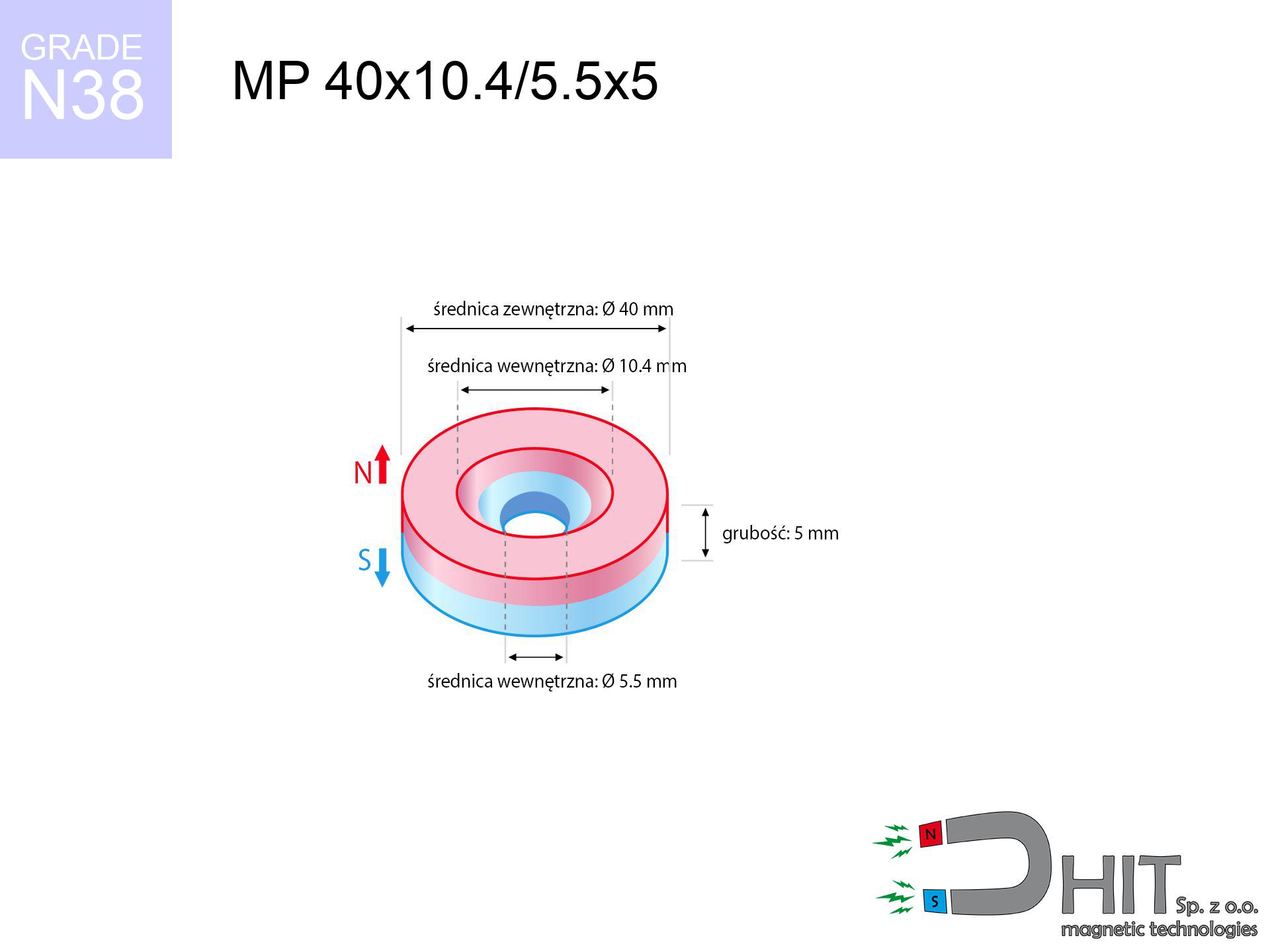

MP 40x10.4/5.5x5 / N38 - ring magnet

ring magnet

Catalog no 030249

GTIN/EAN: 5906301812258

Diameter

40 mm [±0,1 mm]

internal diameter Ø

10.4/5.5 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

46.23 g

Magnetization Direction

↑ axial

Load capacity

9.47 kg / 92.86 N

Magnetic Induction

150.36 mT / 1504 Gs

Coating

[NiCuNi] Nickel

27.00 ZŁ with VAT / pcs + price for transport

21.95 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

if you prefer let us know using

request form

our website.

Parameters as well as shape of neodymium magnets can be checked with our

our magnetic calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical - MP 40x10.4/5.5x5 / N38 - ring magnet

Specification / characteristics - MP 40x10.4/5.5x5 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030249 |

| GTIN/EAN | 5906301812258 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 40 mm [±0,1 mm] |

| internal diameter Ø | 10.4/5.5 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 46.23 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 9.47 kg / 92.86 N |

| Magnetic Induction ~ ? | 150.36 mT / 1504 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the product - report

The following values are the outcome of a physical calculation. Results rely on algorithms for the class Nd2Fe14B. Actual parameters might slightly deviate from the simulation results. Please consider these data as a preliminary roadmap for designers.

Table 1: Static pull force (force vs distance) - characteristics

MP 40x10.4/5.5x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1289 Gs

128.9 mT

|

9.47 kg / 20.88 pounds

9470.0 g / 92.9 N

|

strong |

| 1 mm |

1265 Gs

126.5 mT

|

9.12 kg / 20.11 pounds

9120.9 g / 89.5 N

|

strong |

| 2 mm |

1232 Gs

123.2 mT

|

8.66 kg / 19.10 pounds

8662.7 g / 85.0 N

|

strong |

| 3 mm |

1193 Gs

119.3 mT

|

8.12 kg / 17.90 pounds

8121.3 g / 79.7 N

|

strong |

| 5 mm |

1099 Gs

109.9 mT

|

6.89 kg / 15.18 pounds

6887.8 g / 67.6 N

|

strong |

| 10 mm |

825 Gs

82.5 mT

|

3.88 kg / 8.56 pounds

3882.0 g / 38.1 N

|

strong |

| 15 mm |

580 Gs

58.0 mT

|

1.92 kg / 4.22 pounds

1915.5 g / 18.8 N

|

low risk |

| 20 mm |

399 Gs

39.9 mT

|

0.91 kg / 2.00 pounds

908.3 g / 8.9 N

|

low risk |

| 30 mm |

195 Gs

19.5 mT

|

0.22 kg / 0.48 pounds

217.6 g / 2.1 N

|

low risk |

| 50 mm |

61 Gs

6.1 mT

|

0.02 kg / 0.05 pounds

21.0 g / 0.2 N

|

low risk |

Table 2: Sliding load (wall)

MP 40x10.4/5.5x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.89 kg / 4.18 pounds

1894.0 g / 18.6 N

|

| 1 mm | Stal (~0.2) |

1.82 kg / 4.02 pounds

1824.0 g / 17.9 N

|

| 2 mm | Stal (~0.2) |

1.73 kg / 3.82 pounds

1732.0 g / 17.0 N

|

| 3 mm | Stal (~0.2) |

1.62 kg / 3.58 pounds

1624.0 g / 15.9 N

|

| 5 mm | Stal (~0.2) |

1.38 kg / 3.04 pounds

1378.0 g / 13.5 N

|

| 10 mm | Stal (~0.2) |

0.78 kg / 1.71 pounds

776.0 g / 7.6 N

|

| 15 mm | Stal (~0.2) |

0.38 kg / 0.85 pounds

384.0 g / 3.8 N

|

| 20 mm | Stal (~0.2) |

0.18 kg / 0.40 pounds

182.0 g / 1.8 N

|

| 30 mm | Stal (~0.2) |

0.04 kg / 0.10 pounds

44.0 g / 0.4 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.01 pounds

4.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MP 40x10.4/5.5x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.84 kg / 6.26 pounds

2841.0 g / 27.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.89 kg / 4.18 pounds

1894.0 g / 18.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.95 kg / 2.09 pounds

947.0 g / 9.3 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

4.74 kg / 10.44 pounds

4735.0 g / 46.5 N

|

Table 4: Material efficiency (substrate influence) - power losses

MP 40x10.4/5.5x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.95 kg / 2.09 pounds

947.0 g / 9.3 N

|

| 1 mm |

|

2.37 kg / 5.22 pounds

2367.5 g / 23.2 N

|

| 2 mm |

|

4.74 kg / 10.44 pounds

4735.0 g / 46.5 N

|

| 3 mm |

|

7.10 kg / 15.66 pounds

7102.5 g / 69.7 N

|

| 5 mm |

|

9.47 kg / 20.88 pounds

9470.0 g / 92.9 N

|

| 10 mm |

|

9.47 kg / 20.88 pounds

9470.0 g / 92.9 N

|

| 11 mm |

|

9.47 kg / 20.88 pounds

9470.0 g / 92.9 N

|

| 12 mm |

|

9.47 kg / 20.88 pounds

9470.0 g / 92.9 N

|

Table 5: Thermal stability (stability) - thermal limit

MP 40x10.4/5.5x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

9.47 kg / 20.88 pounds

9470.0 g / 92.9 N

|

OK |

| 40 °C | -2.2% |

9.26 kg / 20.42 pounds

9261.7 g / 90.9 N

|

OK |

| 60 °C | -4.4% |

9.05 kg / 19.96 pounds

9053.3 g / 88.8 N

|

|

| 80 °C | -6.6% |

8.84 kg / 19.50 pounds

8845.0 g / 86.8 N

|

|

| 100 °C | -28.8% |

6.74 kg / 14.86 pounds

6742.6 g / 66.1 N

|

Table 6: Two magnets (attraction) - field collision

MP 40x10.4/5.5x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

10.73 kg / 23.65 pounds

2 424 Gs

|

1.61 kg / 3.55 pounds

1609 g / 15.8 N

|

N/A |

| 1 mm |

10.55 kg / 23.25 pounds

2 555 Gs

|

1.58 kg / 3.49 pounds

1582 g / 15.5 N

|

9.49 kg / 20.93 pounds

~0 Gs

|

| 2 mm |

10.33 kg / 22.78 pounds

2 529 Gs

|

1.55 kg / 3.42 pounds

1550 g / 15.2 N

|

9.30 kg / 20.50 pounds

~0 Gs

|

| 3 mm |

10.09 kg / 22.23 pounds

2 499 Gs

|

1.51 kg / 3.34 pounds

1513 g / 14.8 N

|

9.08 kg / 20.01 pounds

~0 Gs

|

| 5 mm |

9.52 kg / 20.98 pounds

2 427 Gs

|

1.43 kg / 3.15 pounds

1427 g / 14.0 N

|

8.56 kg / 18.88 pounds

~0 Gs

|

| 10 mm |

7.80 kg / 17.20 pounds

2 198 Gs

|

1.17 kg / 2.58 pounds

1170 g / 11.5 N

|

7.02 kg / 15.48 pounds

~0 Gs

|

| 20 mm |

4.40 kg / 9.69 pounds

1 650 Gs

|

0.66 kg / 1.45 pounds

660 g / 6.5 N

|

3.96 kg / 8.72 pounds

~0 Gs

|

| 50 mm |

0.49 kg / 1.09 pounds

553 Gs

|

0.07 kg / 0.16 pounds

74 g / 0.7 N

|

0.44 kg / 0.98 pounds

~0 Gs

|

| 60 mm |

0.25 kg / 0.54 pounds

391 Gs

|

0.04 kg / 0.08 pounds

37 g / 0.4 N

|

0.22 kg / 0.49 pounds

~0 Gs

|

| 70 mm |

0.13 kg / 0.28 pounds

282 Gs

|

0.02 kg / 0.04 pounds

19 g / 0.2 N

|

0.12 kg / 0.26 pounds

~0 Gs

|

| 80 mm |

0.07 kg / 0.15 pounds

209 Gs

|

0.01 kg / 0.02 pounds

11 g / 0.1 N

|

0.06 kg / 0.14 pounds

~0 Gs

|

| 90 mm |

0.04 kg / 0.09 pounds

158 Gs

|

0.01 kg / 0.01 pounds

6 g / 0.1 N

|

0.04 kg / 0.08 pounds

~0 Gs

|

| 100 mm |

0.02 kg / 0.05 pounds

121 Gs

|

0.00 kg / 0.01 pounds

4 g / 0.0 N

|

0.02 kg / 0.05 pounds

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MP 40x10.4/5.5x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 12.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 10.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 8.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 6.0 cm |

| Car key | 50 Gs (5.0 mT) | 5.5 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Impact energy (kinetic energy) - warning

MP 40x10.4/5.5x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

17.75 km/h

(4.93 m/s)

|

0.56 J | |

| 30 mm |

25.36 km/h

(7.04 m/s)

|

1.15 J | |

| 50 mm |

32.32 km/h

(8.98 m/s)

|

1.86 J | |

| 100 mm |

45.65 km/h

(12.68 m/s)

|

3.72 J |

Table 9: Surface protection spec

MP 40x10.4/5.5x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MP 40x10.4/5.5x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 17 767 Mx | 177.7 µWb |

| Pc Coefficient | 0.17 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MP 40x10.4/5.5x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 9.47 kg | Standard |

| Water (riverbed) |

10.84 kg

(+1.37 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Caution: On a vertical surface, the magnet holds just approx. 20-30% of its nominal pull.

2. Steel thickness impact

*Thin steel (e.g. computer case) severely weakens the holding force.

3. Heat tolerance

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.17

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more proposals

Advantages and disadvantages of rare earth magnets.

Benefits

- They retain magnetic properties for nearly 10 years – the loss is just ~1% (in theory),

- They retain their magnetic properties even under strong external field,

- In other words, due to the metallic layer of nickel, the element looks attractive,

- Magnets have very high magnetic induction on the active area,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can work (depending on the shape) even at a temperature of 230°C or more...

- Thanks to the option of accurate forming and adaptation to unique solutions, neodymium magnets can be modeled in a wide range of geometric configurations, which amplifies use scope,

- Wide application in advanced technology sectors – they are utilized in computer drives, brushless drives, advanced medical instruments, also industrial machines.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Disadvantages

- They are fragile upon too strong impacts. To avoid cracks, it is worth securing magnets in a protective case. Such protection not only shields the magnet but also improves its resistance to damage

- Neodymium magnets lose their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture, in case of application outdoors

- We suggest a housing - magnetic mechanism, due to difficulties in producing threads inside the magnet and complex forms.

- Potential hazard to health – tiny shards of magnets pose a threat, when accidentally swallowed, which is particularly important in the context of child safety. Additionally, tiny parts of these devices are able to complicate diagnosis medical when they are in the body.

- Due to neodymium price, their price is higher than average,

Lifting parameters

Maximum lifting capacity of the magnet – what contributes to it?

- on a block made of structural steel, optimally conducting the magnetic flux

- possessing a massiveness of at least 10 mm to avoid saturation

- with an ground contact surface

- under conditions of no distance (surface-to-surface)

- for force acting at a right angle (in the magnet axis)

- at temperature approx. 20 degrees Celsius

Practical lifting capacity: influencing factors

- Gap between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by veneer or unevenness) significantly weakens the pulling force, often by half at just 0.5 mm.

- Force direction – remember that the magnet has greatest strength perpendicularly. Under shear forces, the holding force drops significantly, often to levels of 20-30% of the maximum value.

- Steel thickness – too thin sheet causes magnetic saturation, causing part of the flux to be escaped into the air.

- Steel grade – the best choice is high-permeability steel. Stainless steels may generate lower lifting capacity.

- Plate texture – smooth surfaces guarantee perfect abutment, which improves field saturation. Rough surfaces reduce efficiency.

- Thermal conditions – NdFeB sinters have a negative temperature coefficient. At higher temperatures they lose power, and at low temperatures gain strength (up to a certain limit).

Holding force was checked on the plate surface of 20 mm thickness, when the force acted perpendicularly, however under shearing force the holding force is lower. In addition, even a minimal clearance between the magnet and the plate decreases the load capacity.

Safe handling of neodymium magnets

Crushing force

Big blocks can smash fingers in a fraction of a second. Do not put your hand betwixt two attracting surfaces.

GPS Danger

Note: rare earth magnets generate a field that disrupts precision electronics. Maintain a separation from your mobile, device, and navigation systems.

Nickel allergy

Nickel alert: The nickel-copper-nickel coating contains nickel. If an allergic reaction appears, cease handling magnets and use protective gear.

Maximum temperature

Keep cool. NdFeB magnets are sensitive to heat. If you require resistance above 80°C, look for special high-temperature series (H, SH, UH).

Material brittleness

Despite the nickel coating, the material is brittle and cannot withstand shocks. Do not hit, as the magnet may shatter into sharp, dangerous pieces.

Electronic devices

Do not bring magnets close to a purse, laptop, or screen. The magnetic field can irreversibly ruin these devices and erase data from cards.

Choking Hazard

Neodymium magnets are not suitable for play. Swallowing multiple magnets can lead to them attracting across intestines, which poses a direct threat to life and necessitates immediate surgery.

Dust is flammable

Mechanical processing of neodymium magnets carries a risk of fire hazard. Neodymium dust reacts violently with oxygen and is hard to extinguish.

Handling guide

Before starting, read the rules. Sudden snapping can break the magnet or hurt your hand. Be predictive.

Implant safety

Warning for patients: Strong magnetic fields affect electronics. Keep at least 30 cm distance or request help to work with the magnets.

![UMGZ 60x30x15 [M10] GZ / N38 - magnetic holder external thread UMGZ 60x30x15 [M10] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umgw-60x30x15-m10-gz-bas.jpg)