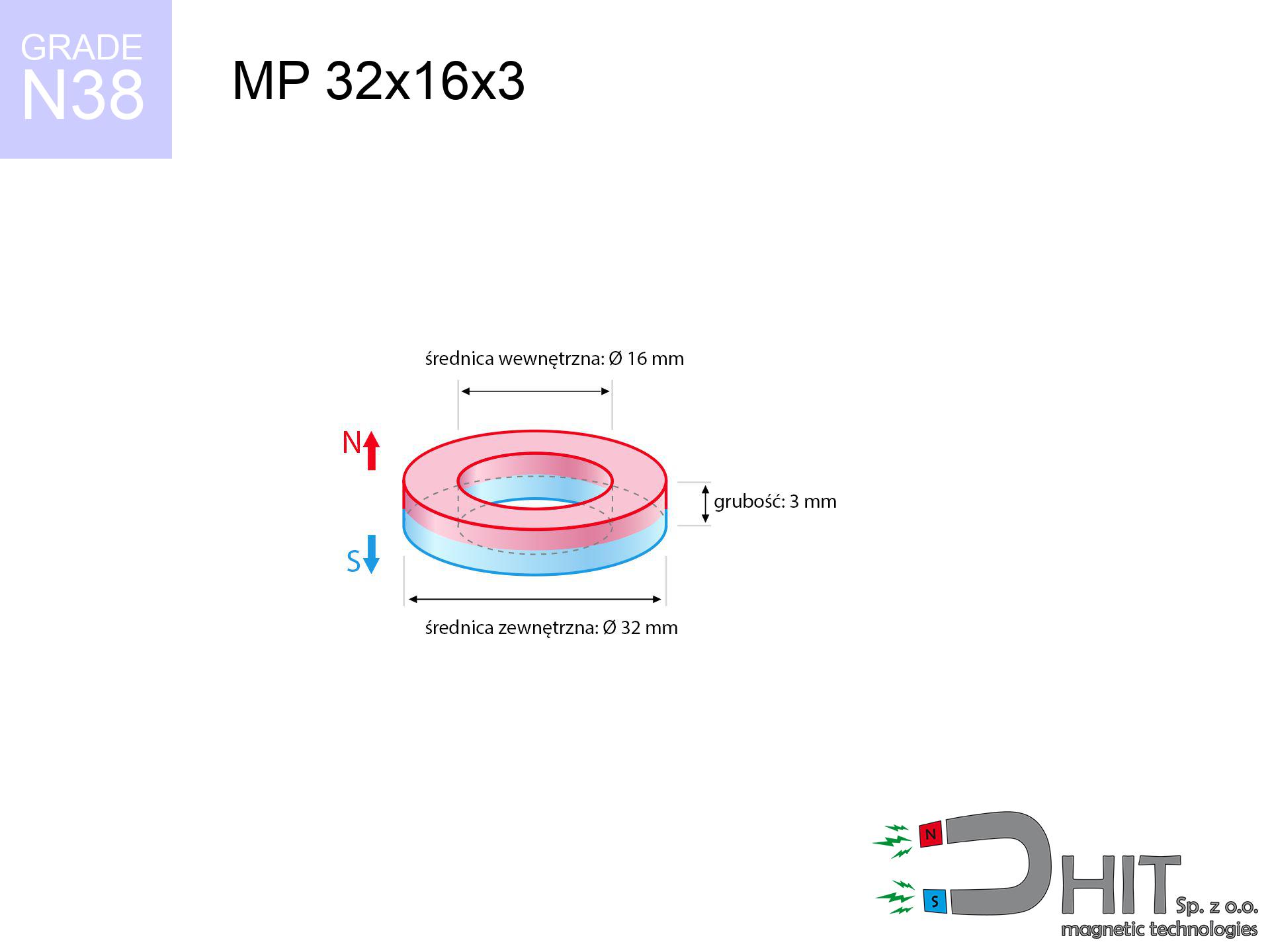

MP 32x16x3 / N38 - ring magnet

ring magnet

Catalog no 030198

GTIN/EAN: 5906301812159

Diameter

32 mm [±0,1 mm]

internal diameter Ø

16 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

13.57 g

Magnetization Direction

↑ axial

Load capacity

2.79 kg / 27.40 N

Magnetic Induction

114.25 mT / 1142 Gs

Coating

[NiCuNi] Nickel

5.24 ZŁ with VAT / pcs + price for transport

4.26 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

otherwise get in touch using

form

the contact section.

Parameters and structure of a neodymium magnet can be reviewed on our

power calculator.

Same-day processing for orders placed before 14:00.

Product card - MP 32x16x3 / N38 - ring magnet

Specification / characteristics - MP 32x16x3 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030198 |

| GTIN/EAN | 5906301812159 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 32 mm [±0,1 mm] |

| internal diameter Ø | 16 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 13.57 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.79 kg / 27.40 N |

| Magnetic Induction ~ ? | 114.25 mT / 1142 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the magnet - data

The following data represent the result of a physical simulation. Results were calculated on algorithms for the material Nd2Fe14B. Operational parameters might slightly differ from theoretical values. Please consider these calculations as a preliminary roadmap when designing systems.

Table 1: Static pull force (pull vs gap) - power drop

MP 32x16x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5552 Gs

555.2 mT

|

2.79 kg / 6.15 LBS

2790.0 g / 27.4 N

|

strong |

| 1 mm |

5202 Gs

520.2 mT

|

2.45 kg / 5.40 LBS

2448.8 g / 24.0 N

|

strong |

| 2 mm |

4850 Gs

485.0 mT

|

2.13 kg / 4.69 LBS

2128.7 g / 20.9 N

|

strong |

| 3 mm |

4504 Gs

450.4 mT

|

1.84 kg / 4.05 LBS

1836.3 g / 18.0 N

|

low risk |

| 5 mm |

3849 Gs

384.9 mT

|

1.34 kg / 2.96 LBS

1340.5 g / 13.2 N

|

low risk |

| 10 mm |

2513 Gs

251.3 mT

|

0.57 kg / 1.26 LBS

571.6 g / 5.6 N

|

low risk |

| 15 mm |

1633 Gs

163.3 mT

|

0.24 kg / 0.53 LBS

241.2 g / 2.4 N

|

low risk |

| 20 mm |

1087 Gs

108.7 mT

|

0.11 kg / 0.24 LBS

107.0 g / 1.0 N

|

low risk |

| 30 mm |

535 Gs

53.5 mT

|

0.03 kg / 0.06 LBS

25.9 g / 0.3 N

|

low risk |

| 50 mm |

181 Gs

18.1 mT

|

0.00 kg / 0.01 LBS

3.0 g / 0.0 N

|

low risk |

Table 2: Slippage capacity (vertical surface)

MP 32x16x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.56 kg / 1.23 LBS

558.0 g / 5.5 N

|

| 1 mm | Stal (~0.2) |

0.49 kg / 1.08 LBS

490.0 g / 4.8 N

|

| 2 mm | Stal (~0.2) |

0.43 kg / 0.94 LBS

426.0 g / 4.2 N

|

| 3 mm | Stal (~0.2) |

0.37 kg / 0.81 LBS

368.0 g / 3.6 N

|

| 5 mm | Stal (~0.2) |

0.27 kg / 0.59 LBS

268.0 g / 2.6 N

|

| 10 mm | Stal (~0.2) |

0.11 kg / 0.25 LBS

114.0 g / 1.1 N

|

| 15 mm | Stal (~0.2) |

0.05 kg / 0.11 LBS

48.0 g / 0.5 N

|

| 20 mm | Stal (~0.2) |

0.02 kg / 0.05 LBS

22.0 g / 0.2 N

|

| 30 mm | Stal (~0.2) |

0.01 kg / 0.01 LBS

6.0 g / 0.1 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MP 32x16x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.84 kg / 1.85 LBS

837.0 g / 8.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.56 kg / 1.23 LBS

558.0 g / 5.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.28 kg / 0.62 LBS

279.0 g / 2.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.40 kg / 3.08 LBS

1395.0 g / 13.7 N

|

Table 4: Material efficiency (saturation) - power losses

MP 32x16x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.28 kg / 0.62 LBS

279.0 g / 2.7 N

|

| 1 mm |

|

0.70 kg / 1.54 LBS

697.5 g / 6.8 N

|

| 2 mm |

|

1.40 kg / 3.08 LBS

1395.0 g / 13.7 N

|

| 3 mm |

|

2.09 kg / 4.61 LBS

2092.5 g / 20.5 N

|

| 5 mm |

|

2.79 kg / 6.15 LBS

2790.0 g / 27.4 N

|

| 10 mm |

|

2.79 kg / 6.15 LBS

2790.0 g / 27.4 N

|

| 11 mm |

|

2.79 kg / 6.15 LBS

2790.0 g / 27.4 N

|

| 12 mm |

|

2.79 kg / 6.15 LBS

2790.0 g / 27.4 N

|

Table 5: Thermal stability (stability) - thermal limit

MP 32x16x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.79 kg / 6.15 LBS

2790.0 g / 27.4 N

|

OK |

| 40 °C | -2.2% |

2.73 kg / 6.02 LBS

2728.6 g / 26.8 N

|

OK |

| 60 °C | -4.4% |

2.67 kg / 5.88 LBS

2667.2 g / 26.2 N

|

OK |

| 80 °C | -6.6% |

2.61 kg / 5.74 LBS

2605.9 g / 25.6 N

|

|

| 100 °C | -28.8% |

1.99 kg / 4.38 LBS

1986.5 g / 19.5 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MP 32x16x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

128.78 kg / 283.90 LBS

6 014 Gs

|

19.32 kg / 42.59 LBS

19317 g / 189.5 N

|

N/A |

| 1 mm |

120.86 kg / 266.44 LBS

10 757 Gs

|

18.13 kg / 39.97 LBS

18128 g / 177.8 N

|

108.77 kg / 239.80 LBS

~0 Gs

|

| 2 mm |

113.03 kg / 249.19 LBS

10 403 Gs

|

16.95 kg / 37.38 LBS

16954 g / 166.3 N

|

101.73 kg / 224.27 LBS

~0 Gs

|

| 3 mm |

105.49 kg / 232.56 LBS

10 050 Gs

|

15.82 kg / 34.88 LBS

15823 g / 155.2 N

|

94.94 kg / 209.31 LBS

~0 Gs

|

| 5 mm |

91.34 kg / 201.37 LBS

9 352 Gs

|

13.70 kg / 30.21 LBS

13701 g / 134.4 N

|

82.21 kg / 181.23 LBS

~0 Gs

|

| 10 mm |

61.88 kg / 136.41 LBS

7 697 Gs

|

9.28 kg / 20.46 LBS

9281 g / 91.0 N

|

55.69 kg / 122.77 LBS

~0 Gs

|

| 20 mm |

26.38 kg / 58.16 LBS

5 026 Gs

|

3.96 kg / 8.72 LBS

3957 g / 38.8 N

|

23.74 kg / 52.35 LBS

~0 Gs

|

| 50 mm |

2.35 kg / 5.17 LBS

1 499 Gs

|

0.35 kg / 0.78 LBS

352 g / 3.5 N

|

2.11 kg / 4.66 LBS

~0 Gs

|

| 60 mm |

1.19 kg / 2.63 LBS

1 069 Gs

|

0.18 kg / 0.39 LBS

179 g / 1.8 N

|

1.07 kg / 2.37 LBS

~0 Gs

|

| 70 mm |

0.65 kg / 1.42 LBS

786 Gs

|

0.10 kg / 0.21 LBS

97 g / 1.0 N

|

0.58 kg / 1.28 LBS

~0 Gs

|

| 80 mm |

0.37 kg / 0.81 LBS

594 Gs

|

0.06 kg / 0.12 LBS

55 g / 0.5 N

|

0.33 kg / 0.73 LBS

~0 Gs

|

| 90 mm |

0.22 kg / 0.49 LBS

459 Gs

|

0.03 kg / 0.07 LBS

33 g / 0.3 N

|

0.20 kg / 0.44 LBS

~0 Gs

|

| 100 mm |

0.14 kg / 0.30 LBS

362 Gs

|

0.02 kg / 0.05 LBS

21 g / 0.2 N

|

0.12 kg / 0.27 LBS

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MP 32x16x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 20.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 16.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 12.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 9.5 cm |

| Car key | 50 Gs (5.0 mT) | 9.0 cm |

| Payment card | 400 Gs (40.0 mT) | 3.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MP 32x16x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

16.21 km/h

(4.50 m/s)

|

0.14 J | |

| 30 mm |

25.19 km/h

(7.00 m/s)

|

0.33 J | |

| 50 mm |

32.36 km/h

(8.99 m/s)

|

0.55 J | |

| 100 mm |

45.73 km/h

(12.70 m/s)

|

1.09 J |

Table 9: Corrosion resistance

MP 32x16x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MP 32x16x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 38 808 Mx | 388.1 µWb |

| Pc Coefficient | 0.90 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MP 32x16x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.79 kg | Standard |

| Water (riverbed) |

3.19 kg

(+0.40 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical surface, the magnet holds merely a fraction of its max power.

2. Steel thickness impact

*Thin metal sheet (e.g. 0.5mm PC case) drastically weakens the holding force.

3. Thermal stability

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.90

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also offers

Advantages and disadvantages of rare earth magnets.

Advantages

- They virtually do not lose power, because even after ten years the performance loss is only ~1% (based on calculations),

- They feature excellent resistance to magnetism drop as a result of external fields,

- A magnet with a metallic silver surface has better aesthetics,

- The surface of neodymium magnets generates a powerful magnetic field – this is one of their assets,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the form) even at high temperatures reaching 230°C or more...

- Thanks to freedom in forming and the capacity to modify to complex applications,

- Huge importance in modern industrial fields – they are utilized in magnetic memories, electric motors, medical devices, as well as other advanced devices.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Cons

- Brittleness is one of their disadvantages. Upon strong impact they can break. We recommend keeping them in a special holder, which not only secures them against impacts but also increases their durability

- We warn that neodymium magnets can reduce their power at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material immune to moisture, in case of application outdoors

- Limited possibility of creating threads in the magnet and complex shapes - preferred is a housing - mounting mechanism.

- Health risk to health – tiny shards of magnets are risky, if swallowed, which is particularly important in the aspect of protecting the youngest. It is also worth noting that tiny parts of these products can complicate diagnosis medical after entering the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Pull force analysis

Maximum holding power of the magnet – what affects it?

- using a base made of high-permeability steel, serving as a circuit closing element

- whose transverse dimension equals approx. 10 mm

- characterized by lack of roughness

- with direct contact (without paint)

- for force acting at a right angle (in the magnet axis)

- in temp. approx. 20°C

Practical lifting capacity: influencing factors

- Distance – existence of foreign body (rust, dirt, gap) interrupts the magnetic circuit, which reduces capacity steeply (even by 50% at 0.5 mm).

- Loading method – declared lifting capacity refers to detachment vertically. When slipping, the magnet holds significantly lower power (often approx. 20-30% of nominal force).

- Metal thickness – thin material does not allow full use of the magnet. Part of the magnetic field penetrates through instead of generating force.

- Metal type – not every steel reacts the same. Alloy additives weaken the attraction effect.

- Surface finish – full contact is obtained only on polished steel. Any scratches and bumps reduce the real contact area, reducing force.

- Thermal factor – hot environment reduces magnetic field. Too high temperature can permanently demagnetize the magnet.

Lifting capacity was measured with the use of a steel plate with a smooth surface of suitable thickness (min. 20 mm), under perpendicular pulling force, in contrast under attempts to slide the magnet the holding force is lower. Additionally, even a small distance between the magnet and the plate decreases the holding force.

Precautions when working with neodymium magnets

Safe distance

Avoid bringing magnets close to a purse, computer, or screen. The magnetic field can permanently damage these devices and erase data from cards.

Nickel allergy

Some people have a contact allergy to Ni, which is the common plating for neodymium magnets. Extended handling might lead to a rash. We suggest wear safety gloves.

Phone sensors

A powerful magnetic field disrupts the functioning of compasses in phones and navigation systems. Keep magnets near a device to prevent damaging the sensors.

Operating temperature

Regular neodymium magnets (grade N) lose power when the temperature surpasses 80°C. Damage is permanent.

Handling guide

Handle with care. Neodymium magnets act from a distance and snap with massive power, often faster than you can react.

Machining danger

Powder produced during grinding of magnets is combustible. Do not drill into magnets without proper cooling and knowledge.

Swallowing risk

These products are not suitable for play. Swallowing multiple magnets may result in them pinching intestinal walls, which poses a direct threat to life and necessitates immediate surgery.

Material brittleness

Beware of splinters. Magnets can fracture upon violent connection, ejecting sharp fragments into the air. Eye protection is mandatory.

Crushing force

Large magnets can crush fingers in a fraction of a second. Under no circumstances put your hand between two attracting surfaces.

Medical interference

Warning for patients: Strong magnetic fields affect electronics. Maintain minimum 30 cm distance or ask another person to work with the magnets.

![UMP 75x25 [M10x3] GW F200 GOLD DUAL Lina / N42 - search holder UMP 75x25 [M10x3] GW F200 GOLD DUAL Lina / N42 - search holder](https://cdn3.dhit.pl/graphics/products/ump-75x25-m10x3-gw-f200-gold-x2-lina-car.jpg)

![AM ucho [M10] - magnetic accessories AM ucho [M10] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-ucho-m10-tij.jpg)