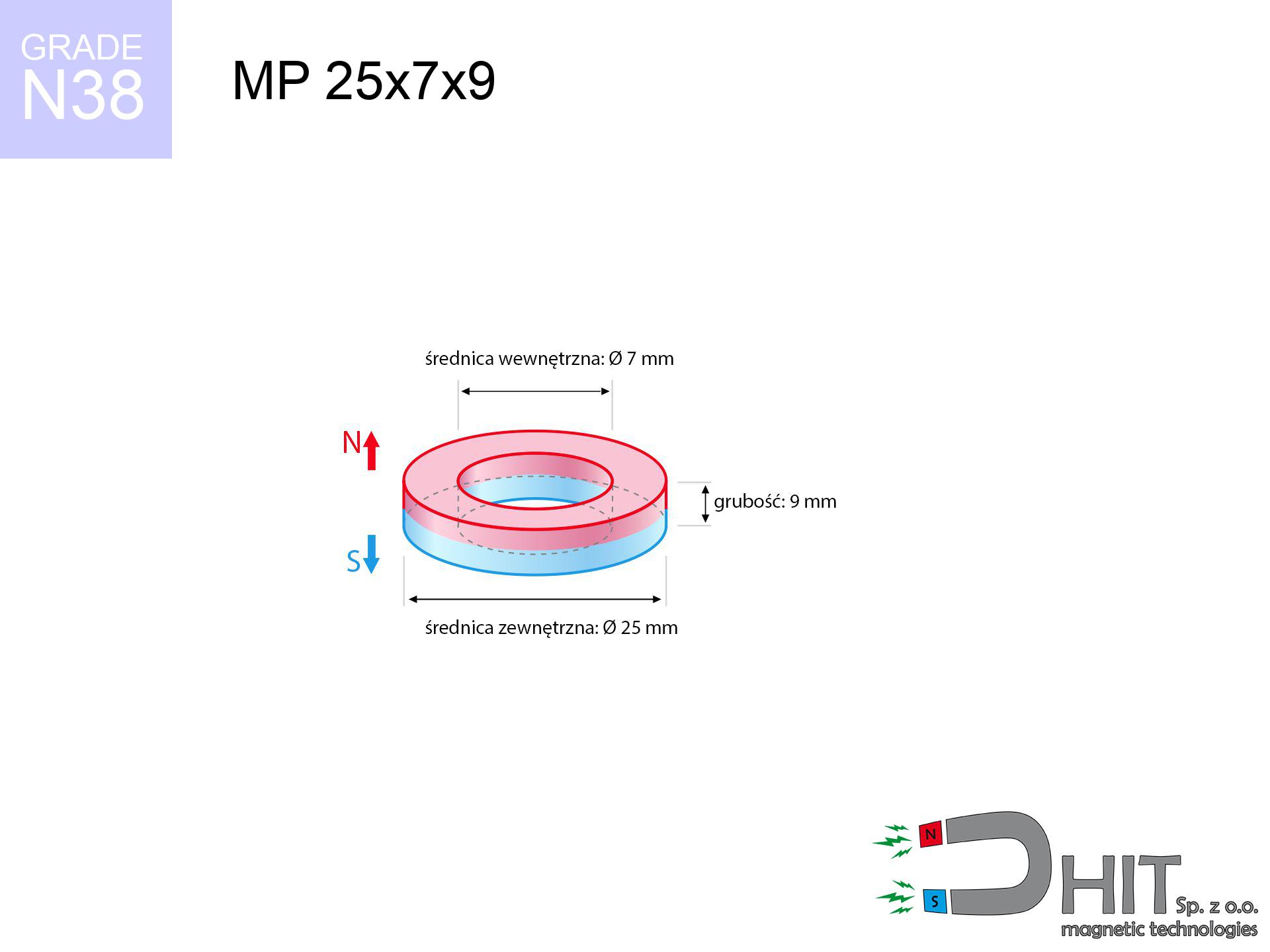

MP 25x7x9 / N38 - ring magnet

ring magnet

Catalog no 030195

GTIN/EAN: 5906301812128

Diameter

25 mm [±0,1 mm]

internal diameter Ø

7 mm [±0,1 mm]

Height

9 mm [±0,1 mm]

Weight

30.54 g

Magnetization Direction

↑ axial

Load capacity

14.82 kg / 145.39 N

Magnetic Induction

362.13 mT / 3621 Gs

Coating

[NiCuNi] Nickel

12.55 ZŁ with VAT / pcs + price for transport

10.20 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

if you prefer get in touch through

request form

the contact form page.

Lifting power along with form of magnetic components can be analyzed using our

magnetic calculator.

Same-day processing for orders placed before 14:00.

Physical properties - MP 25x7x9 / N38 - ring magnet

Specification / characteristics - MP 25x7x9 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030195 |

| GTIN/EAN | 5906301812128 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 25 mm [±0,1 mm] |

| internal diameter Ø | 7 mm [±0,1 mm] |

| Height | 9 mm [±0,1 mm] |

| Weight | 30.54 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 14.82 kg / 145.39 N |

| Magnetic Induction ~ ? | 362.13 mT / 3621 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the product - report

These information represent the outcome of a mathematical simulation. Values are based on algorithms for the material Nd2Fe14B. Actual performance might slightly differ from theoretical values. Treat these calculations as a preliminary roadmap for designers.

Table 1: Static force (force vs distance) - interaction chart

MP 25x7x9 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5777 Gs

577.7 mT

|

14.82 kg / 32.67 LBS

14820.0 g / 145.4 N

|

dangerous! |

| 1 mm |

5310 Gs

531.0 mT

|

12.52 kg / 27.60 LBS

12519.6 g / 122.8 N

|

dangerous! |

| 2 mm |

4846 Gs

484.6 mT

|

10.43 kg / 22.98 LBS

10425.5 g / 102.3 N

|

dangerous! |

| 3 mm |

4397 Gs

439.7 mT

|

8.59 kg / 18.93 LBS

8586.1 g / 84.2 N

|

strong |

| 5 mm |

3576 Gs

357.6 mT

|

5.68 kg / 12.52 LBS

5678.0 g / 55.7 N

|

strong |

| 10 mm |

2073 Gs

207.3 mT

|

1.91 kg / 4.21 LBS

1907.5 g / 18.7 N

|

safe |

| 15 mm |

1231 Gs

123.1 mT

|

0.67 kg / 1.48 LBS

673.1 g / 6.6 N

|

safe |

| 20 mm |

773 Gs

77.3 mT

|

0.27 kg / 0.58 LBS

265.0 g / 2.6 N

|

safe |

| 30 mm |

356 Gs

35.6 mT

|

0.06 kg / 0.12 LBS

56.2 g / 0.6 N

|

safe |

| 50 mm |

115 Gs

11.5 mT

|

0.01 kg / 0.01 LBS

5.9 g / 0.1 N

|

safe |

Table 2: Shear capacity (wall)

MP 25x7x9 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

2.96 kg / 6.53 LBS

2964.0 g / 29.1 N

|

| 1 mm | Stal (~0.2) |

2.50 kg / 5.52 LBS

2504.0 g / 24.6 N

|

| 2 mm | Stal (~0.2) |

2.09 kg / 4.60 LBS

2086.0 g / 20.5 N

|

| 3 mm | Stal (~0.2) |

1.72 kg / 3.79 LBS

1718.0 g / 16.9 N

|

| 5 mm | Stal (~0.2) |

1.14 kg / 2.50 LBS

1136.0 g / 11.1 N

|

| 10 mm | Stal (~0.2) |

0.38 kg / 0.84 LBS

382.0 g / 3.7 N

|

| 15 mm | Stal (~0.2) |

0.13 kg / 0.30 LBS

134.0 g / 1.3 N

|

| 20 mm | Stal (~0.2) |

0.05 kg / 0.12 LBS

54.0 g / 0.5 N

|

| 30 mm | Stal (~0.2) |

0.01 kg / 0.03 LBS

12.0 g / 0.1 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - vertical pull

MP 25x7x9 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

4.45 kg / 9.80 LBS

4446.0 g / 43.6 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

2.96 kg / 6.53 LBS

2964.0 g / 29.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.48 kg / 3.27 LBS

1482.0 g / 14.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

7.41 kg / 16.34 LBS

7410.0 g / 72.7 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MP 25x7x9 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.74 kg / 1.63 LBS

741.0 g / 7.3 N

|

| 1 mm |

|

1.85 kg / 4.08 LBS

1852.5 g / 18.2 N

|

| 2 mm |

|

3.71 kg / 8.17 LBS

3705.0 g / 36.3 N

|

| 3 mm |

|

5.56 kg / 12.25 LBS

5557.5 g / 54.5 N

|

| 5 mm |

|

9.26 kg / 20.42 LBS

9262.5 g / 90.9 N

|

| 10 mm |

|

14.82 kg / 32.67 LBS

14820.0 g / 145.4 N

|

| 11 mm |

|

14.82 kg / 32.67 LBS

14820.0 g / 145.4 N

|

| 12 mm |

|

14.82 kg / 32.67 LBS

14820.0 g / 145.4 N

|

Table 5: Thermal resistance (material behavior) - resistance threshold

MP 25x7x9 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

14.82 kg / 32.67 LBS

14820.0 g / 145.4 N

|

OK |

| 40 °C | -2.2% |

14.49 kg / 31.95 LBS

14494.0 g / 142.2 N

|

OK |

| 60 °C | -4.4% |

14.17 kg / 31.23 LBS

14167.9 g / 139.0 N

|

OK |

| 80 °C | -6.6% |

13.84 kg / 30.52 LBS

13841.9 g / 135.8 N

|

|

| 100 °C | -28.8% |

10.55 kg / 23.26 LBS

10551.8 g / 103.5 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MP 25x7x9 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

74.73 kg / 164.76 LBS

6 082 Gs

|

11.21 kg / 24.71 LBS

11210 g / 110.0 N

|

N/A |

| 1 mm |

68.86 kg / 151.81 LBS

11 091 Gs

|

10.33 kg / 22.77 LBS

10329 g / 101.3 N

|

61.97 kg / 136.63 LBS

~0 Gs

|

| 2 mm |

63.13 kg / 139.18 LBS

10 620 Gs

|

9.47 kg / 20.88 LBS

9470 g / 92.9 N

|

56.82 kg / 125.26 LBS

~0 Gs

|

| 3 mm |

57.70 kg / 127.20 LBS

10 153 Gs

|

8.65 kg / 19.08 LBS

8654 g / 84.9 N

|

51.93 kg / 114.48 LBS

~0 Gs

|

| 5 mm |

47.77 kg / 105.31 LBS

9 238 Gs

|

7.17 kg / 15.80 LBS

7165 g / 70.3 N

|

42.99 kg / 94.78 LBS

~0 Gs

|

| 10 mm |

28.63 kg / 63.12 LBS

7 152 Gs

|

4.29 kg / 9.47 LBS

4295 g / 42.1 N

|

25.77 kg / 56.81 LBS

~0 Gs

|

| 20 mm |

9.62 kg / 21.21 LBS

4 145 Gs

|

1.44 kg / 3.18 LBS

1443 g / 14.2 N

|

8.66 kg / 19.09 LBS

~0 Gs

|

| 50 mm |

0.59 kg / 1.29 LBS

1 024 Gs

|

0.09 kg / 0.19 LBS

88 g / 0.9 N

|

0.53 kg / 1.16 LBS

~0 Gs

|

| 60 mm |

0.28 kg / 0.62 LBS

712 Gs

|

0.04 kg / 0.09 LBS

43 g / 0.4 N

|

0.26 kg / 0.56 LBS

~0 Gs

|

| 70 mm |

0.15 kg / 0.33 LBS

514 Gs

|

0.02 kg / 0.05 LBS

22 g / 0.2 N

|

0.13 kg / 0.29 LBS

~0 Gs

|

| 80 mm |

0.08 kg / 0.18 LBS

383 Gs

|

0.01 kg / 0.03 LBS

12 g / 0.1 N

|

0.07 kg / 0.16 LBS

~0 Gs

|

| 90 mm |

0.05 kg / 0.11 LBS

293 Gs

|

0.01 kg / 0.02 LBS

7 g / 0.1 N

|

0.04 kg / 0.10 LBS

~0 Gs

|

| 100 mm |

0.03 kg / 0.07 LBS

230 Gs

|

0.00 kg / 0.01 LBS

4 g / 0.0 N

|

0.03 kg / 0.06 LBS

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MP 25x7x9 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 17.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 13.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 10.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 8.0 cm |

| Car key | 50 Gs (5.0 mT) | 7.5 cm |

| Payment card | 400 Gs (40.0 mT) | 3.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Collisions (kinetic energy) - warning

MP 25x7x9 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

23.94 km/h

(6.65 m/s)

|

0.68 J | |

| 30 mm |

38.57 km/h

(10.71 m/s)

|

1.75 J | |

| 50 mm |

49.69 km/h

(13.80 m/s)

|

2.91 J | |

| 100 mm |

70.25 km/h

(19.52 m/s)

|

5.82 J |

Table 9: Surface protection spec

MP 25x7x9 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MP 25x7x9 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 22 495 Mx | 225.0 µWb |

| Pc Coefficient | 1.05 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MP 25x7x9 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 14.82 kg | Standard |

| Water (riverbed) |

16.97 kg

(+2.15 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Warning: On a vertical surface, the magnet retains just ~20% of its nominal pull.

2. Efficiency vs thickness

*Thin steel (e.g. 0.5mm PC case) significantly weakens the holding force.

3. Heat tolerance

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.05

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Strengths and weaknesses of rare earth magnets.

Strengths

- They do not lose magnetism, even during approximately ten years – the decrease in lifting capacity is only ~1% (according to tests),

- They are noted for resistance to demagnetization induced by presence of other magnetic fields,

- The use of an aesthetic finish of noble metals (nickel, gold, silver) causes the element to present itself better,

- Magnetic induction on the working part of the magnet turns out to be very high,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and are able to act (depending on the shape) even at a temperature of 230°C or more...

- Thanks to the potential of accurate molding and adaptation to specialized projects, magnetic components can be modeled in a broad palette of forms and dimensions, which expands the range of possible applications,

- Wide application in modern technologies – they are commonly used in data components, electric drive systems, medical devices, as well as technologically advanced constructions.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Weaknesses

- To avoid cracks upon strong impacts, we recommend using special steel housings. Such a solution secures the magnet and simultaneously increases its durability.

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation and corrosion.

- We suggest casing - magnetic holder, due to difficulties in creating threads inside the magnet and complex shapes.

- Possible danger related to microscopic parts of magnets pose a threat, in case of ingestion, which gains importance in the aspect of protecting the youngest. Additionally, small components of these magnets are able to disrupt the diagnostic process medical in case of swallowing.

- With budget limitations the cost of neodymium magnets can be a barrier,

Pull force analysis

Detachment force of the magnet in optimal conditions – what it depends on?

- using a plate made of low-carbon steel, serving as a magnetic yoke

- with a cross-section no less than 10 mm

- characterized by smoothness

- with zero gap (no coatings)

- for force acting at a right angle (in the magnet axis)

- at conditions approx. 20°C

Magnet lifting force in use – key factors

- Distance – existence of foreign body (paint, dirt, air) interrupts the magnetic circuit, which reduces power steeply (even by 50% at 0.5 mm).

- Angle of force application – maximum parameter is available only during pulling at a 90° angle. The resistance to sliding of the magnet along the plate is standardly several times lower (approx. 1/5 of the lifting capacity).

- Element thickness – for full efficiency, the steel must be sufficiently thick. Paper-thin metal limits the lifting capacity (the magnet "punches through" it).

- Steel type – low-carbon steel gives the best results. Higher carbon content decrease magnetic properties and lifting capacity.

- Smoothness – full contact is obtained only on smooth steel. Rough texture create air cushions, reducing force.

- Thermal factor – high temperature reduces pulling force. Too high temperature can permanently demagnetize the magnet.

Lifting capacity was determined by applying a steel plate with a smooth surface of suitable thickness (min. 20 mm), under perpendicular detachment force, in contrast under shearing force the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet’s surface and the plate reduces the holding force.

H&S for magnets

Hand protection

Protect your hands. Two large magnets will snap together immediately with a force of massive weight, crushing everything in their path. Be careful!

Impact on smartphones

Navigation devices and smartphones are highly susceptible to magnetic fields. Close proximity with a powerful NdFeB magnet can permanently damage the internal compass in your phone.

Power loss in heat

Regular neodymium magnets (grade N) undergo demagnetization when the temperature exceeds 80°C. This process is irreversible.

Data carriers

Powerful magnetic fields can erase data on credit cards, hard drives, and storage devices. Stay away of at least 10 cm.

Nickel coating and allergies

A percentage of the population suffer from a hypersensitivity to Ni, which is the common plating for neodymium magnets. Prolonged contact might lead to an allergic reaction. We strongly advise wear protective gloves.

Magnets are brittle

Neodymium magnets are sintered ceramics, which means they are prone to chipping. Collision of two magnets will cause them shattering into shards.

Adults only

Adult use only. Tiny parts can be swallowed, leading to intestinal necrosis. Store away from kids and pets.

Fire warning

Powder generated during machining of magnets is flammable. Do not drill into magnets without proper cooling and knowledge.

Do not underestimate power

Use magnets with awareness. Their powerful strength can surprise even experienced users. Be vigilant and respect their power.

Pacemakers

Life threat: Strong magnets can turn off heart devices and defibrillators. Stay away if you have medical devices.

![SM 25x175 [2xM8] / N52 - magnetic separator SM 25x175 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x175-2xm8-gif.jpg)

![UMGZ 25x17x8 [M5] GZ / N38 - magnetic holder external thread UMGZ 25x17x8 [M5] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/um-25x17x8-m5-gz-keb.jpg)