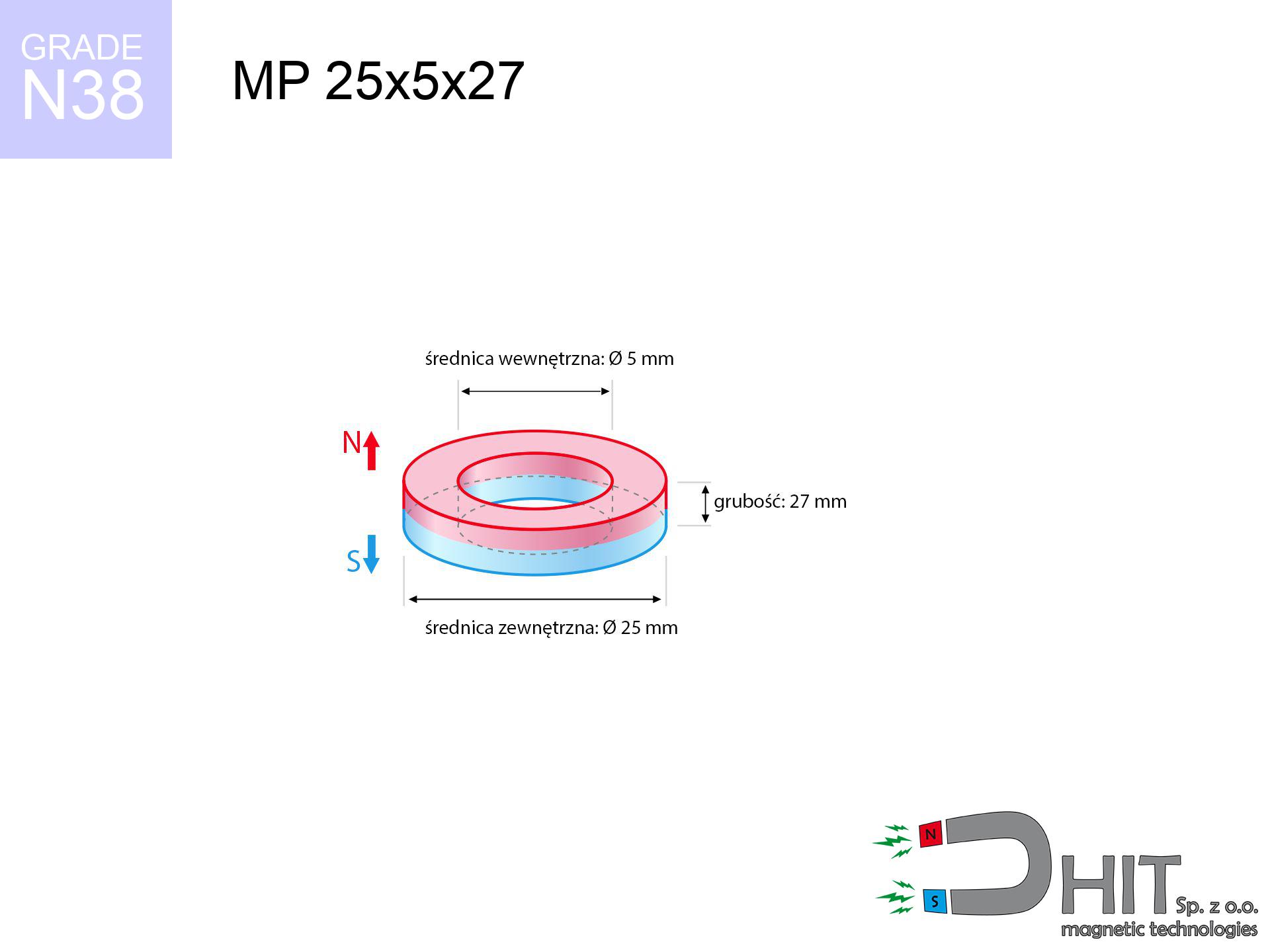

MP 25x5x27 / N38 - ring magnet

ring magnet

Catalog no 030192

GTIN/EAN: 5906301812098

Diameter

25 mm [±0,1 mm]

internal diameter Ø

5 mm [±0,1 mm]

Height

27 mm [±0,1 mm]

Weight

95.43 g

Magnetization Direction

↑ axial

Load capacity

18.51 kg / 181.54 N

Magnetic Induction

562.34 mT / 5623 Gs

Coating

[NiCuNi] Nickel

47.18 ZŁ with VAT / pcs + price for transport

38.36 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

otherwise drop us a message via

our online form

the contact page.

Force as well as form of magnetic components can be calculated using our

our magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Physical properties - MP 25x5x27 / N38 - ring magnet

Specification / characteristics - MP 25x5x27 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030192 |

| GTIN/EAN | 5906301812098 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 25 mm [±0,1 mm] |

| internal diameter Ø | 5 mm [±0,1 mm] |

| Height | 27 mm [±0,1 mm] |

| Weight | 95.43 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 18.51 kg / 181.54 N |

| Magnetic Induction ~ ? | 562.34 mT / 5623 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the magnet - technical parameters

These data constitute the outcome of a mathematical simulation. Values were calculated on models for the material Nd2Fe14B. Operational parameters might slightly deviate from the simulation results. Treat these calculations as a supplementary guide for designers.

Table 1: Static pull force (force vs distance) - power drop

MP 25x5x27 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5716 Gs

571.6 mT

|

18.51 kg / 40.81 LBS

18510.0 g / 181.6 N

|

crushing |

| 1 mm |

5288 Gs

528.8 mT

|

15.84 kg / 34.92 LBS

15839.8 g / 155.4 N

|

crushing |

| 2 mm |

4861 Gs

486.1 mT

|

13.38 kg / 29.51 LBS

13384.0 g / 131.3 N

|

crushing |

| 3 mm |

4446 Gs

444.6 mT

|

11.20 kg / 24.69 LBS

11198.0 g / 109.9 N

|

crushing |

| 5 mm |

3677 Gs

367.7 mT

|

7.66 kg / 16.88 LBS

7657.5 g / 75.1 N

|

warning |

| 10 mm |

2216 Gs

221.6 mT

|

2.78 kg / 6.13 LBS

2782.1 g / 27.3 N

|

warning |

| 15 mm |

1354 Gs

135.4 mT

|

1.04 kg / 2.29 LBS

1037.8 g / 10.2 N

|

safe |

| 20 mm |

864 Gs

86.4 mT

|

0.42 kg / 0.93 LBS

423.3 g / 4.2 N

|

safe |

| 30 mm |

405 Gs

40.5 mT

|

0.09 kg / 0.21 LBS

93.1 g / 0.9 N

|

safe |

| 50 mm |

133 Gs

13.3 mT

|

0.01 kg / 0.02 LBS

10.0 g / 0.1 N

|

safe |

Table 2: Vertical force (wall)

MP 25x5x27 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

3.70 kg / 8.16 LBS

3702.0 g / 36.3 N

|

| 1 mm | Stal (~0.2) |

3.17 kg / 6.98 LBS

3168.0 g / 31.1 N

|

| 2 mm | Stal (~0.2) |

2.68 kg / 5.90 LBS

2676.0 g / 26.3 N

|

| 3 mm | Stal (~0.2) |

2.24 kg / 4.94 LBS

2240.0 g / 22.0 N

|

| 5 mm | Stal (~0.2) |

1.53 kg / 3.38 LBS

1532.0 g / 15.0 N

|

| 10 mm | Stal (~0.2) |

0.56 kg / 1.23 LBS

556.0 g / 5.5 N

|

| 15 mm | Stal (~0.2) |

0.21 kg / 0.46 LBS

208.0 g / 2.0 N

|

| 20 mm | Stal (~0.2) |

0.08 kg / 0.19 LBS

84.0 g / 0.8 N

|

| 30 mm | Stal (~0.2) |

0.02 kg / 0.04 LBS

18.0 g / 0.2 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MP 25x5x27 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

5.55 kg / 12.24 LBS

5553.0 g / 54.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

3.70 kg / 8.16 LBS

3702.0 g / 36.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.85 kg / 4.08 LBS

1851.0 g / 18.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

9.26 kg / 20.40 LBS

9255.0 g / 90.8 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MP 25x5x27 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.93 kg / 2.04 LBS

925.5 g / 9.1 N

|

| 1 mm |

|

2.31 kg / 5.10 LBS

2313.8 g / 22.7 N

|

| 2 mm |

|

4.63 kg / 10.20 LBS

4627.5 g / 45.4 N

|

| 3 mm |

|

6.94 kg / 15.30 LBS

6941.3 g / 68.1 N

|

| 5 mm |

|

11.57 kg / 25.50 LBS

11568.8 g / 113.5 N

|

| 10 mm |

|

18.51 kg / 40.81 LBS

18510.0 g / 181.6 N

|

| 11 mm |

|

18.51 kg / 40.81 LBS

18510.0 g / 181.6 N

|

| 12 mm |

|

18.51 kg / 40.81 LBS

18510.0 g / 181.6 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MP 25x5x27 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

18.51 kg / 40.81 LBS

18510.0 g / 181.6 N

|

OK |

| 40 °C | -2.2% |

18.10 kg / 39.91 LBS

18102.8 g / 177.6 N

|

OK |

| 60 °C | -4.4% |

17.70 kg / 39.01 LBS

17695.6 g / 173.6 N

|

OK |

| 80 °C | -6.6% |

17.29 kg / 38.11 LBS

17288.3 g / 169.6 N

|

|

| 100 °C | -28.8% |

13.18 kg / 29.05 LBS

13179.1 g / 129.3 N

|

Table 6: Two magnets (repulsion) - field collision

MP 25x5x27 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

13.99 kg / 30.83 LBS

6 064 Gs

|

2.10 kg / 4.62 LBS

2098 g / 20.6 N

|

N/A |

| 1 mm |

12.97 kg / 28.59 LBS

11 008 Gs

|

1.94 kg / 4.29 LBS

1945 g / 19.1 N

|

11.67 kg / 25.73 LBS

~0 Gs

|

| 2 mm |

11.97 kg / 26.39 LBS

10 576 Gs

|

1.80 kg / 3.96 LBS

1795 g / 17.6 N

|

10.77 kg / 23.75 LBS

~0 Gs

|

| 3 mm |

11.02 kg / 24.29 LBS

10 146 Gs

|

1.65 kg / 3.64 LBS

1652 g / 16.2 N

|

9.91 kg / 21.86 LBS

~0 Gs

|

| 5 mm |

9.26 kg / 20.42 LBS

9 303 Gs

|

1.39 kg / 3.06 LBS

1389 g / 13.6 N

|

8.33 kg / 18.37 LBS

~0 Gs

|

| 10 mm |

5.79 kg / 12.76 LBS

7 353 Gs

|

0.87 kg / 1.91 LBS

868 g / 8.5 N

|

5.21 kg / 11.48 LBS

~0 Gs

|

| 20 mm |

2.10 kg / 4.63 LBS

4 432 Gs

|

0.32 kg / 0.70 LBS

315 g / 3.1 N

|

1.89 kg / 4.17 LBS

~0 Gs

|

| 50 mm |

0.14 kg / 0.32 LBS

1 159 Gs

|

0.02 kg / 0.05 LBS

22 g / 0.2 N

|

0.13 kg / 0.29 LBS

~0 Gs

|

| 60 mm |

0.07 kg / 0.16 LBS

811 Gs

|

0.01 kg / 0.02 LBS

11 g / 0.1 N

|

0.06 kg / 0.14 LBS

~0 Gs

|

| 70 mm |

0.04 kg / 0.08 LBS

589 Gs

|

0.01 kg / 0.01 LBS

6 g / 0.1 N

|

0.03 kg / 0.07 LBS

~0 Gs

|

| 80 mm |

0.02 kg / 0.05 LBS

440 Gs

|

0.00 kg / 0.01 LBS

3 g / 0.0 N

|

0.02 kg / 0.04 LBS

~0 Gs

|

| 90 mm |

0.01 kg / 0.03 LBS

338 Gs

|

0.00 kg / 0.00 LBS

2 g / 0.0 N

|

0.01 kg / 0.02 LBS

~0 Gs

|

| 100 mm |

0.01 kg / 0.02 LBS

265 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - warnings

MP 25x5x27 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 18.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 14.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 11.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 8.5 cm |

| Car key | 50 Gs (5.0 mT) | 7.5 cm |

| Payment card | 400 Gs (40.0 mT) | 3.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Impact energy (kinetic energy) - warning

MP 25x5x27 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

15.31 km/h

(4.25 m/s)

|

0.86 J | |

| 30 mm |

24.40 km/h

(6.78 m/s)

|

2.19 J | |

| 50 mm |

31.42 km/h

(8.73 m/s)

|

3.63 J | |

| 100 mm |

44.42 km/h

(12.34 m/s)

|

7.26 J |

Table 9: Corrosion resistance

MP 25x5x27 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MP 25x5x27 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 4 917 Mx | 49.2 µWb |

| Pc Coefficient | 1.40 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MP 25x5x27 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 18.51 kg | Standard |

| Water (riverbed) |

21.19 kg

(+2.68 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Warning: On a vertical surface, the magnet holds just a fraction of its perpendicular strength.

2. Plate thickness effect

*Thin metal sheet (e.g. 0.5mm PC case) severely reduces the holding force.

3. Heat tolerance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.40

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more offers

Strengths and weaknesses of Nd2Fe14B magnets.

Pros

- They have stable power, and over around ten years their performance decreases symbolically – ~1% (according to theory),

- They are noted for resistance to demagnetization induced by external disturbances,

- By using a reflective coating of silver, the element acquires an professional look,

- Magnets exhibit extremely high magnetic induction on the working surface,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can work (depending on the shape) even at a temperature of 230°C or more...

- Thanks to versatility in designing and the ability to customize to complex applications,

- Versatile presence in modern industrial fields – they are commonly used in hard drives, electric motors, medical equipment, as well as industrial machines.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Weaknesses

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can break. We advise keeping them in a special holder, which not only secures them against impacts but also raises their durability

- Neodymium magnets lose their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation as well as corrosion.

- Due to limitations in creating nuts and complicated forms in magnets, we recommend using cover - magnetic mechanism.

- Potential hazard resulting from small fragments of magnets can be dangerous, when accidentally swallowed, which becomes key in the context of child safety. Additionally, tiny parts of these products can complicate diagnosis medical in case of swallowing.

- With mass production the cost of neodymium magnets can be a barrier,

Lifting parameters

Magnetic strength at its maximum – what it depends on?

- with the application of a yoke made of special test steel, guaranteeing maximum field concentration

- whose thickness reaches at least 10 mm

- with an ideally smooth contact surface

- with total lack of distance (no impurities)

- for force applied at a right angle (in the magnet axis)

- in neutral thermal conditions

Impact of factors on magnetic holding capacity in practice

- Distance (between the magnet and the plate), as even a microscopic distance (e.g. 0.5 mm) results in a drastic drop in lifting capacity by up to 50% (this also applies to paint, corrosion or debris).

- Load vector – highest force is available only during perpendicular pulling. The force required to slide of the magnet along the plate is standardly several times lower (approx. 1/5 of the lifting capacity).

- Steel thickness – insufficiently thick sheet does not accept the full field, causing part of the flux to be lost into the air.

- Material type – ideal substrate is high-permeability steel. Hardened steels may generate lower lifting capacity.

- Smoothness – full contact is possible only on polished steel. Any scratches and bumps reduce the real contact area, weakening the magnet.

- Thermal conditions – NdFeB sinters have a negative temperature coefficient. When it is hot they are weaker, and in frost gain strength (up to a certain limit).

Lifting capacity testing was carried out on a smooth plate of suitable thickness, under perpendicular forces, however under attempts to slide the magnet the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet and the plate reduces the holding force.

Precautions when working with neodymium magnets

Beware of splinters

Despite the nickel coating, the material is brittle and not impact-resistant. Do not hit, as the magnet may shatter into sharp, dangerous pieces.

Powerful field

Handle magnets consciously. Their powerful strength can surprise even professionals. Be vigilant and do not underestimate their force.

Danger to pacemakers

People with a heart stimulator have to maintain an large gap from magnets. The magnetic field can stop the functioning of the implant.

Impact on smartphones

An intense magnetic field interferes with the functioning of magnetometers in smartphones and GPS navigation. Maintain magnets near a device to avoid damaging the sensors.

Flammability

Dust created during machining of magnets is self-igniting. Avoid drilling into magnets unless you are an expert.

Heat sensitivity

Monitor thermal conditions. Exposing the magnet to high heat will destroy its properties and pulling force.

Adults only

These products are not toys. Swallowing multiple magnets may result in them pinching intestinal walls, which poses a severe health hazard and necessitates urgent medical intervention.

Bodily injuries

Danger of trauma: The pulling power is so immense that it can result in hematomas, pinching, and even bone fractures. Use thick gloves.

Keep away from computers

Intense magnetic fields can corrupt files on credit cards, HDDs, and other magnetic media. Keep a distance of min. 10 cm.

Sensitization to coating

Nickel alert: The nickel-copper-nickel coating consists of nickel. If an allergic reaction happens, cease handling magnets and wear gloves.

![UI 17.5x5 [C310] / N38 - badge holder UI 17.5x5 [C310] / N38 - badge holder](https://cdn3.dhit.pl/graphics/products/ui17.5x5-c310-rud.jpg)

![SM 25x100 [2xM8] / N42 - magnetic separator SM 25x100 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x100-2xm8-feg.jpg)