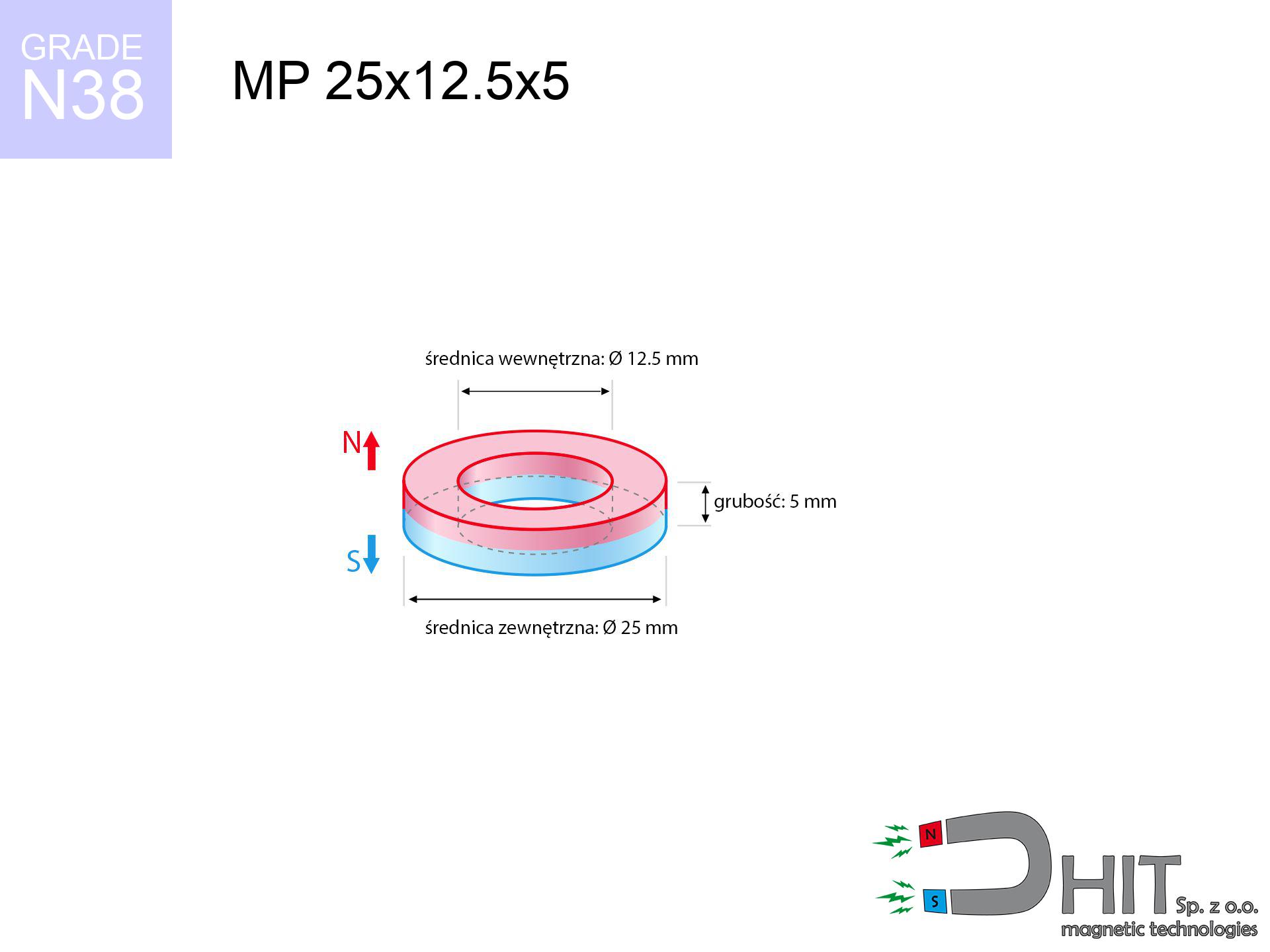

MP 25x12.5x5 / N38 - ring magnet

ring magnet

Catalog no 030342

GTIN/EAN: 5906301812289

Diameter

25 mm [±0,1 mm]

internal diameter Ø

12.5 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

13.81 g

Magnetization Direction

↑ axial

Load capacity

5.98 kg / 58.67 N

Magnetic Induction

230.20 mT / 2302 Gs

Coating

[NiCuNi] Nickel

6.20 ZŁ with VAT / pcs + price for transport

5.04 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

alternatively drop us a message through

our online form

the contact section.

Parameters and structure of a neodymium magnet can be calculated with our

online calculation tool.

Orders submitted before 14:00 will be dispatched today!

Physical properties - MP 25x12.5x5 / N38 - ring magnet

Specification / characteristics - MP 25x12.5x5 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030342 |

| GTIN/EAN | 5906301812289 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 25 mm [±0,1 mm] |

| internal diameter Ø | 12.5 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 13.81 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 5.98 kg / 58.67 N |

| Magnetic Induction ~ ? | 230.20 mT / 2302 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the product - technical parameters

The following data represent the direct effect of a mathematical simulation. Results are based on algorithms for the material Nd2Fe14B. Real-world conditions might slightly differ from theoretical values. Please consider these calculations as a preliminary roadmap for designers.

Table 1: Static pull force (force vs gap) - characteristics

MP 25x12.5x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5777 Gs

577.7 mT

|

5.98 kg / 13.18 pounds

5980.0 g / 58.7 N

|

warning |

| 1 mm |

5310 Gs

531.0 mT

|

5.05 kg / 11.14 pounds

5051.8 g / 49.6 N

|

warning |

| 2 mm |

4846 Gs

484.6 mT

|

4.21 kg / 9.27 pounds

4206.8 g / 41.3 N

|

warning |

| 3 mm |

4397 Gs

439.7 mT

|

3.46 kg / 7.64 pounds

3464.5 g / 34.0 N

|

warning |

| 5 mm |

3576 Gs

357.6 mT

|

2.29 kg / 5.05 pounds

2291.1 g / 22.5 N

|

warning |

| 10 mm |

2073 Gs

207.3 mT

|

0.77 kg / 1.70 pounds

769.7 g / 7.6 N

|

low risk |

| 15 mm |

1231 Gs

123.1 mT

|

0.27 kg / 0.60 pounds

271.6 g / 2.7 N

|

low risk |

| 20 mm |

773 Gs

77.3 mT

|

0.11 kg / 0.24 pounds

106.9 g / 1.0 N

|

low risk |

| 30 mm |

356 Gs

35.6 mT

|

0.02 kg / 0.05 pounds

22.7 g / 0.2 N

|

low risk |

| 50 mm |

115 Gs

11.5 mT

|

0.00 kg / 0.01 pounds

2.4 g / 0.0 N

|

low risk |

Table 2: Vertical capacity (vertical surface)

MP 25x12.5x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.20 kg / 2.64 pounds

1196.0 g / 11.7 N

|

| 1 mm | Stal (~0.2) |

1.01 kg / 2.23 pounds

1010.0 g / 9.9 N

|

| 2 mm | Stal (~0.2) |

0.84 kg / 1.86 pounds

842.0 g / 8.3 N

|

| 3 mm | Stal (~0.2) |

0.69 kg / 1.53 pounds

692.0 g / 6.8 N

|

| 5 mm | Stal (~0.2) |

0.46 kg / 1.01 pounds

458.0 g / 4.5 N

|

| 10 mm | Stal (~0.2) |

0.15 kg / 0.34 pounds

154.0 g / 1.5 N

|

| 15 mm | Stal (~0.2) |

0.05 kg / 0.12 pounds

54.0 g / 0.5 N

|

| 20 mm | Stal (~0.2) |

0.02 kg / 0.05 pounds

22.0 g / 0.2 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.01 pounds

4.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MP 25x12.5x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.79 kg / 3.96 pounds

1794.0 g / 17.6 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.20 kg / 2.64 pounds

1196.0 g / 11.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.60 kg / 1.32 pounds

598.0 g / 5.9 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.99 kg / 6.59 pounds

2990.0 g / 29.3 N

|

Table 4: Steel thickness (substrate influence) - power losses

MP 25x12.5x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.60 kg / 1.32 pounds

598.0 g / 5.9 N

|

| 1 mm |

|

1.50 kg / 3.30 pounds

1495.0 g / 14.7 N

|

| 2 mm |

|

2.99 kg / 6.59 pounds

2990.0 g / 29.3 N

|

| 3 mm |

|

4.49 kg / 9.89 pounds

4485.0 g / 44.0 N

|

| 5 mm |

|

5.98 kg / 13.18 pounds

5980.0 g / 58.7 N

|

| 10 mm |

|

5.98 kg / 13.18 pounds

5980.0 g / 58.7 N

|

| 11 mm |

|

5.98 kg / 13.18 pounds

5980.0 g / 58.7 N

|

| 12 mm |

|

5.98 kg / 13.18 pounds

5980.0 g / 58.7 N

|

Table 5: Thermal stability (material behavior) - power drop

MP 25x12.5x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

5.98 kg / 13.18 pounds

5980.0 g / 58.7 N

|

OK |

| 40 °C | -2.2% |

5.85 kg / 12.89 pounds

5848.4 g / 57.4 N

|

OK |

| 60 °C | -4.4% |

5.72 kg / 12.60 pounds

5716.9 g / 56.1 N

|

OK |

| 80 °C | -6.6% |

5.59 kg / 12.31 pounds

5585.3 g / 54.8 N

|

|

| 100 °C | -28.8% |

4.26 kg / 9.39 pounds

4257.8 g / 41.8 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MP 25x12.5x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

82.42 kg / 181.72 pounds

6 082 Gs

|

12.36 kg / 27.26 pounds

12364 g / 121.3 N

|

N/A |

| 1 mm |

75.95 kg / 167.44 pounds

11 091 Gs

|

11.39 kg / 25.12 pounds

11392 g / 111.8 N

|

68.35 kg / 150.69 pounds

~0 Gs

|

| 2 mm |

69.63 kg / 153.51 pounds

10 620 Gs

|

10.44 kg / 23.03 pounds

10445 g / 102.5 N

|

62.67 kg / 138.16 pounds

~0 Gs

|

| 3 mm |

63.64 kg / 140.29 pounds

10 153 Gs

|

9.55 kg / 21.04 pounds

9545 g / 93.6 N

|

57.27 kg / 126.26 pounds

~0 Gs

|

| 5 mm |

52.69 kg / 116.16 pounds

9 238 Gs

|

7.90 kg / 17.42 pounds

7903 g / 77.5 N

|

47.42 kg / 104.54 pounds

~0 Gs

|

| 10 mm |

31.58 kg / 69.62 pounds

7 152 Gs

|

4.74 kg / 10.44 pounds

4737 g / 46.5 N

|

28.42 kg / 62.66 pounds

~0 Gs

|

| 20 mm |

10.61 kg / 23.39 pounds

4 145 Gs

|

1.59 kg / 3.51 pounds

1591 g / 15.6 N

|

9.55 kg / 21.05 pounds

~0 Gs

|

| 50 mm |

0.65 kg / 1.43 pounds

1 024 Gs

|

0.10 kg / 0.21 pounds

97 g / 1.0 N

|

0.58 kg / 1.28 pounds

~0 Gs

|

| 60 mm |

0.31 kg / 0.69 pounds

712 Gs

|

0.05 kg / 0.10 pounds

47 g / 0.5 N

|

0.28 kg / 0.62 pounds

~0 Gs

|

| 70 mm |

0.16 kg / 0.36 pounds

514 Gs

|

0.02 kg / 0.05 pounds

24 g / 0.2 N

|

0.15 kg / 0.32 pounds

~0 Gs

|

| 80 mm |

0.09 kg / 0.20 pounds

383 Gs

|

0.01 kg / 0.03 pounds

14 g / 0.1 N

|

0.08 kg / 0.18 pounds

~0 Gs

|

| 90 mm |

0.05 kg / 0.12 pounds

293 Gs

|

0.01 kg / 0.02 pounds

8 g / 0.1 N

|

0.05 kg / 0.11 pounds

~0 Gs

|

| 100 mm |

0.03 kg / 0.07 pounds

230 Gs

|

0.00 kg / 0.01 pounds

5 g / 0.0 N

|

0.03 kg / 0.06 pounds

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MP 25x12.5x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 17.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 13.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 10.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 8.0 cm |

| Car key | 50 Gs (5.0 mT) | 7.5 cm |

| Payment card | 400 Gs (40.0 mT) | 3.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Impact energy (kinetic energy) - collision effects

MP 25x12.5x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.61 km/h

(6.28 m/s)

|

0.27 J | |

| 30 mm |

36.44 km/h

(10.12 m/s)

|

0.71 J | |

| 50 mm |

46.94 km/h

(13.04 m/s)

|

1.17 J | |

| 100 mm |

66.37 km/h

(18.43 m/s)

|

2.35 J |

Table 9: Surface protection spec

MP 25x12.5x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MP 25x12.5x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 24 536 Mx | 245.4 µWb |

| Pc Coefficient | 1.03 | High (Stable) |

Table 11: Physics of underwater searching

MP 25x12.5x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 5.98 kg | Standard |

| Water (riverbed) |

6.85 kg

(+0.87 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Caution: On a vertical surface, the magnet retains just approx. 20-30% of its perpendicular strength.

2. Efficiency vs thickness

*Thin metal sheet (e.g. computer case) significantly limits the holding force.

3. Temperature resistance

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.03

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more offers

Advantages as well as disadvantages of rare earth magnets.

Pros

- They virtually do not lose strength, because even after 10 years the performance loss is only ~1% (according to literature),

- They show high resistance to demagnetization induced by external disturbances,

- By applying a smooth coating of silver, the element gains an modern look,

- Magnets exhibit exceptionally strong magnetic induction on the working surface,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and are able to act (depending on the shape) even at a temperature of 230°C or more...

- Possibility of individual machining and adapting to concrete applications,

- Significant place in modern industrial fields – they serve a role in HDD drives, drive modules, advanced medical instruments, as well as industrial machines.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Limitations

- Susceptibility to cracking is one of their disadvantages. Upon strong impact they can fracture. We advise keeping them in a special holder, which not only protects them against impacts but also increases their durability

- Neodymium magnets lose their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- We suggest casing - magnetic holder, due to difficulties in creating nuts inside the magnet and complex forms.

- Potential hazard to health – tiny shards of magnets can be dangerous, in case of ingestion, which becomes key in the context of child health protection. Furthermore, tiny parts of these devices can disrupt the diagnostic process medical after entering the body.

- With large orders the cost of neodymium magnets is economically unviable,

Lifting parameters

Magnetic strength at its maximum – what contributes to it?

- on a plate made of structural steel, effectively closing the magnetic field

- possessing a thickness of at least 10 mm to avoid saturation

- characterized by smoothness

- with zero gap (no coatings)

- under axial force vector (90-degree angle)

- at temperature room level

Determinants of practical lifting force of a magnet

- Distance – the presence of foreign body (paint, dirt, gap) acts as an insulator, which lowers power steeply (even by 50% at 0.5 mm).

- Direction of force – maximum parameter is obtained only during perpendicular pulling. The shear force of the magnet along the surface is standardly many times lower (approx. 1/5 of the lifting capacity).

- Wall thickness – thin material does not allow full use of the magnet. Part of the magnetic field penetrates through instead of generating force.

- Material composition – different alloys attracts identically. Alloy additives weaken the attraction effect.

- Smoothness – full contact is possible only on polished steel. Rough texture reduce the real contact area, reducing force.

- Temperature – heating the magnet causes a temporary drop of induction. It is worth remembering the thermal limit for a given model.

Lifting capacity was measured with the use of a polished steel plate of optimal thickness (min. 20 mm), under perpendicular detachment force, whereas under shearing force the holding force is lower. Moreover, even a small distance between the magnet’s surface and the plate lowers the load capacity.

Safe handling of NdFeB magnets

Magnet fragility

Despite the nickel coating, the material is delicate and not impact-resistant. Do not hit, as the magnet may crumble into hazardous fragments.

Sensitization to coating

Nickel alert: The nickel-copper-nickel coating consists of nickel. If an allergic reaction appears, immediately stop working with magnets and wear gloves.

Keep away from electronics

Be aware: neodymium magnets generate a field that interferes with precision electronics. Maintain a safe distance from your mobile, tablet, and GPS.

Danger to the youngest

Product intended for adults. Small elements can be swallowed, leading to serious injuries. Keep out of reach of children and animals.

Immense force

Handle magnets with awareness. Their immense force can surprise even experienced users. Plan your moves and respect their power.

Heat sensitivity

Do not overheat. NdFeB magnets are susceptible to temperature. If you require resistance above 80°C, ask us about special high-temperature series (H, SH, UH).

Physical harm

Danger of trauma: The attraction force is so great that it can result in blood blisters, crushing, and even bone fractures. Protective gloves are recommended.

Combustion hazard

Drilling and cutting of neodymium magnets carries a risk of fire hazard. Magnetic powder reacts violently with oxygen and is difficult to extinguish.

Magnetic media

Data protection: Neodymium magnets can damage payment cards and delicate electronics (heart implants, hearing aids, mechanical watches).

Life threat

Warning for patients: Strong magnetic fields disrupt electronics. Keep at least 30 cm distance or request help to handle the magnets.

![UMH 32x8x46 [M6] / N38 - magnetic holder with hook UMH 32x8x46 [M6] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-32x8x46-m6-xov.jpg)

![SM 32x425 [2xM8] / N52 - magnetic separator SM 32x425 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x425-2xm8-tas.jpg)