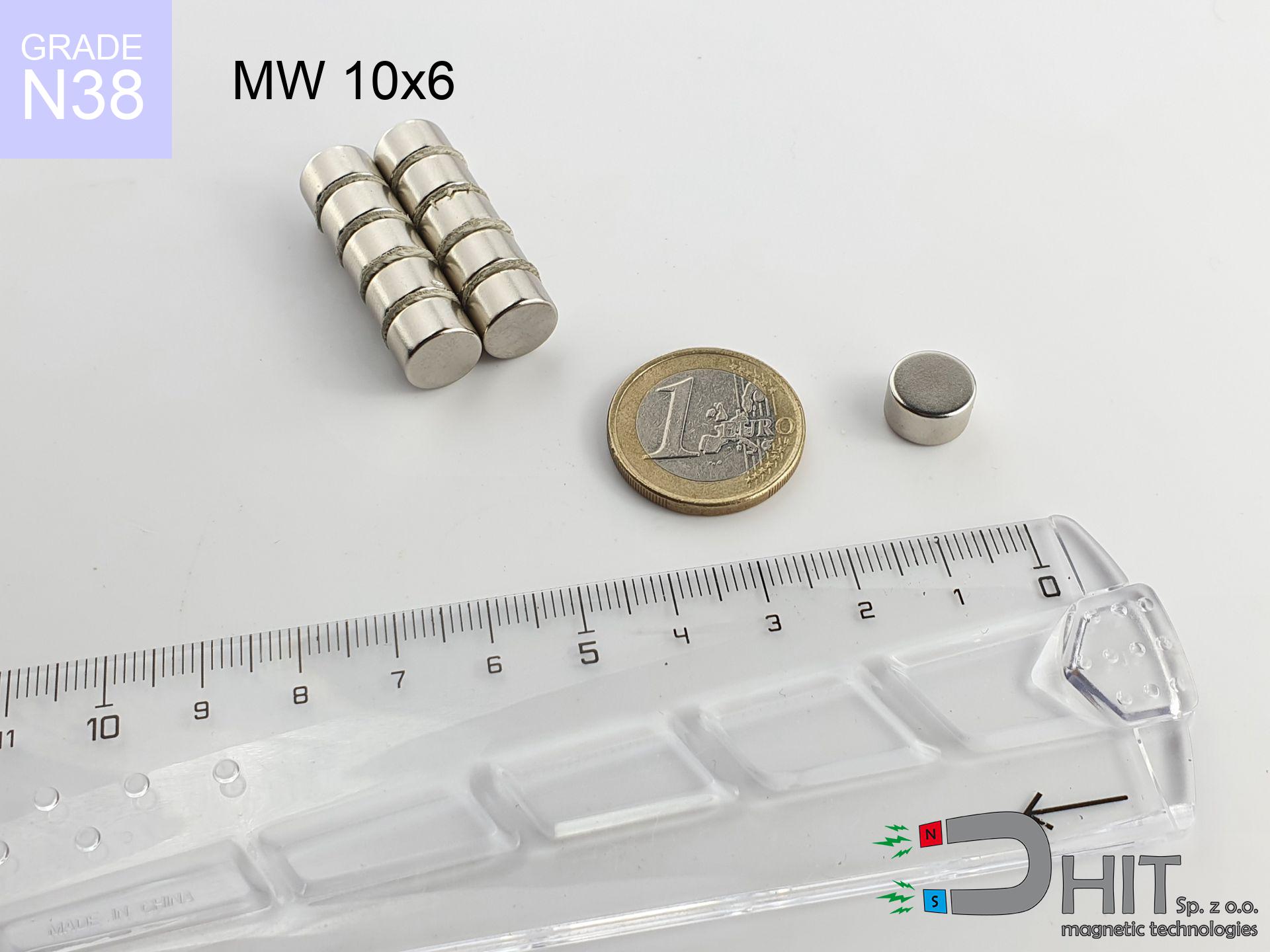

AM Magnetyczny zbieracz / N38 - magnetic accessories

magnetic accessories

Catalog no 080499

Magnetization Direction

↑ axial

Coating

[NiCuNi] Nickel

1.230 ZŁ with VAT / pcs + price for transport

1.000 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

or send us a note using

inquiry form

the contact page.

Weight and shape of magnets can be checked on our

modular calculator.

Same-day shipping for orders placed before 14:00.

Technical of the product - AM Magnetyczny zbieracz / N38 - magnetic accessories

Specification / characteristics - AM Magnetyczny zbieracz / N38 - magnetic accessories

| properties | values |

|---|---|

| Cat. no. | 080499 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Magnetization Direction | ↑ axial |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Pros and cons of neodymium magnets.

Strengths

- They virtually do not lose power, because even after ten years the performance loss is only ~1% (based on calculations),

- They feature excellent resistance to magnetism drop as a result of opposing magnetic fields,

- In other words, due to the reflective surface of silver, the element gains visual value,

- They show high magnetic induction at the operating surface, which improves attraction properties,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Thanks to flexibility in forming and the ability to modify to unusual requirements,

- Huge importance in innovative solutions – they find application in mass storage devices, electric drive systems, advanced medical instruments, and industrial machines.

- Thanks to their power density, small magnets offer high operating force, occupying minimum space,

Cons

- At very strong impacts they can crack, therefore we advise placing them in strong housings. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- Neodymium magnets lose their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- We suggest cover - magnetic holder, due to difficulties in producing threads inside the magnet and complicated forms.

- Possible danger to health – tiny shards of magnets can be dangerous, in case of ingestion, which gains importance in the context of child health protection. Additionally, tiny parts of these magnets are able to be problematic in diagnostics medical when they are in the body.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which hinders application in large quantities

Pull force analysis

Highest magnetic holding force – what affects it?

- using a sheet made of mild steel, functioning as a ideal flux conductor

- whose transverse dimension is min. 10 mm

- with a surface cleaned and smooth

- under conditions of ideal adhesion (surface-to-surface)

- under axial force vector (90-degree angle)

- in neutral thermal conditions

Magnet lifting force in use – key factors

- Space between surfaces – every millimeter of distance (caused e.g. by veneer or unevenness) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Direction of force – maximum parameter is obtained only during perpendicular pulling. The force required to slide of the magnet along the plate is typically many times lower (approx. 1/5 of the lifting capacity).

- Metal thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field penetrates through instead of generating force.

- Steel grade – ideal substrate is high-permeability steel. Stainless steels may attract less.

- Surface finish – ideal contact is possible only on smooth steel. Any scratches and bumps create air cushions, weakening the magnet.

- Temperature – temperature increase results in weakening of force. It is worth remembering the thermal limit for a given model.

Lifting capacity testing was carried out on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, however under attempts to slide the magnet the holding force is lower. Additionally, even a slight gap between the magnet and the plate decreases the load capacity.

Safe handling of neodymium magnets

Nickel allergy

Nickel alert: The Ni-Cu-Ni coating contains nickel. If skin irritation happens, immediately stop handling magnets and use protective gear.

Data carriers

Do not bring magnets near a wallet, computer, or TV. The magnetic field can permanently damage these devices and wipe information from cards.

Medical interference

People with a ICD should keep an absolute distance from magnets. The magnetic field can stop the operation of the implant.

Physical harm

Mind your fingers. Two powerful magnets will snap together instantly with a force of several hundred kilograms, crushing anything in their path. Be careful!

Eye protection

Neodymium magnets are sintered ceramics, meaning they are fragile like glass. Impact of two magnets leads to them breaking into shards.

Handling guide

Use magnets with awareness. Their immense force can surprise even professionals. Be vigilant and do not underestimate their force.

Operating temperature

Avoid heat. Neodymium magnets are sensitive to heat. If you require resistance above 80°C, ask us about special high-temperature series (H, SH, UH).

Machining danger

Combustion risk: Rare earth powder is highly flammable. Avoid machining magnets in home conditions as this may cause fire.

Threat to navigation

A powerful magnetic field negatively affects the operation of magnetometers in phones and GPS navigation. Keep magnets near a device to prevent damaging the sensors.

Keep away from children

Only for adults. Small elements can be swallowed, leading to severe trauma. Keep out of reach of children and animals.

![AM ucho [M8] - magnetic accessories AM ucho [M8] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-ucho-m8-lib.jpg)