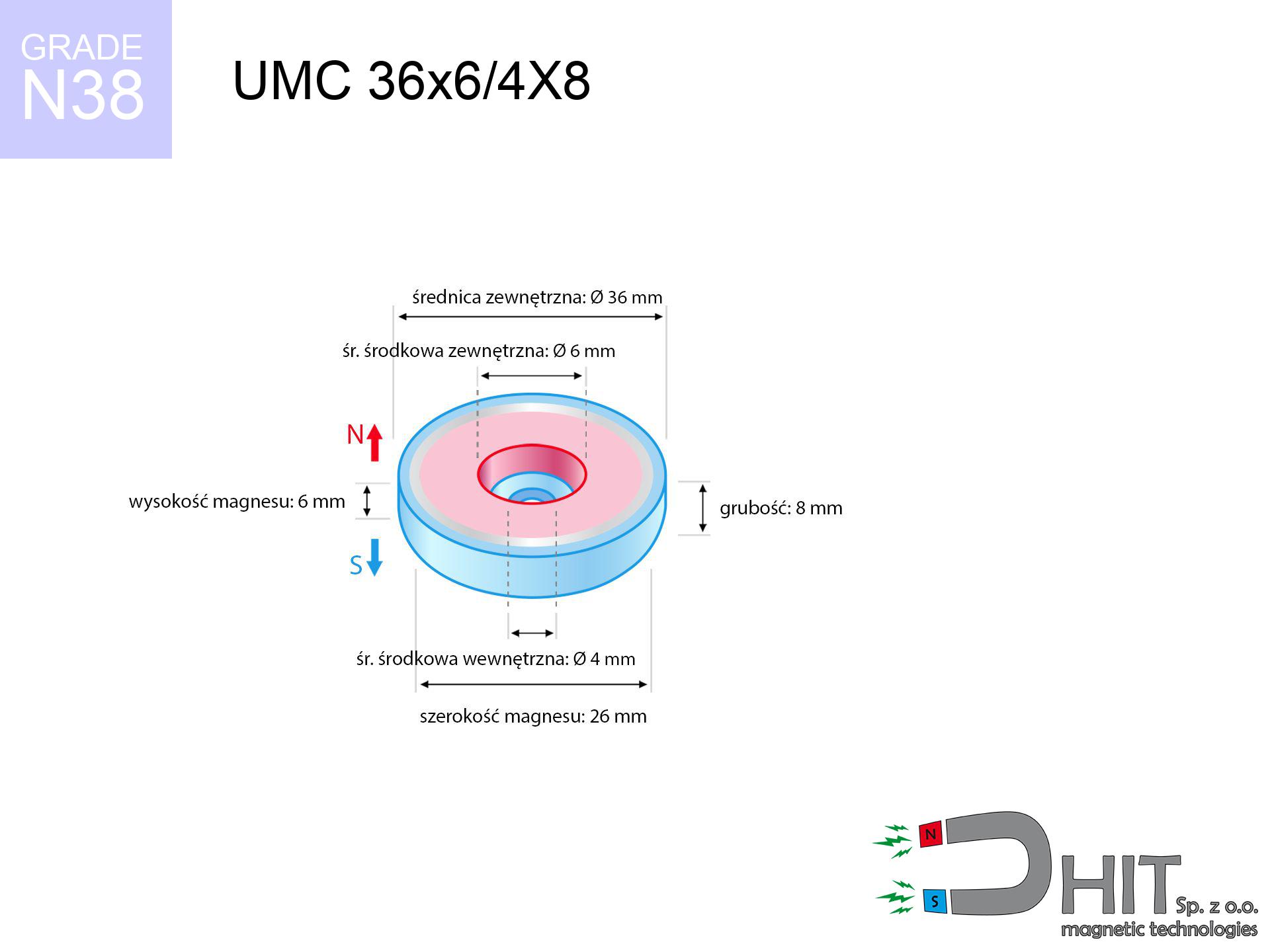

UMC 36x6/4X8 / N38 - cylindrical magnetic holder

cylindrical magnetic holder

Catalog no 320410

GTIN/EAN: 5906301814665

Diameter

36 mm [±1 mm]

internal diameter Ø

6/4 mm [±1 mm]

Height

8 mm [±1 mm]

Weight

45 g

Load capacity

29.00 kg / 284.39 N

Coating

[NiCuNi] Nickel

21.49 ZŁ with VAT / pcs + price for transport

17.47 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?Need advice?

Call us now

+48 888 99 98 98

if you prefer contact us through

inquiry form

through our site.

Parameters along with shape of magnetic components can be tested with our

online calculation tool.

Order by 14:00 and we’ll ship today!

UMC 36x6/4X8 / N38 - cylindrical magnetic holder

Specification / characteristics UMC 36x6/4X8 / N38 - cylindrical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 320410 |

| GTIN/EAN | 5906301814665 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 36 mm [±1 mm] |

| internal diameter Ø | 6/4 mm [±1 mm] |

| Height | 8 mm [±1 mm] |

| Weight | 45 g |

| Load capacity ~ ? | 29.00 kg / 284.39 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Strengths and weaknesses of rare earth magnets.

Strengths

- They have constant strength, and over around ten years their attraction force decreases symbolically – ~1% (according to theory),

- They possess excellent resistance to magnetism drop due to external fields,

- The use of an metallic coating of noble metals (nickel, gold, silver) causes the element to look better,

- Magnets are distinguished by impressive magnetic induction on the outer side,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Possibility of accurate machining and adjusting to precise requirements,

- Versatile presence in future technologies – they are used in computer drives, electromotive mechanisms, diagnostic systems, and multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in tiny dimensions, which makes them useful in compact constructions

Weaknesses

- To avoid cracks under impact, we suggest using special steel housings. Such a solution protects the magnet and simultaneously improves its durability.

- When exposed to high temperature, neodymium magnets experience a drop in strength. Often, when the temperature exceeds 80°C, their power decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which prevent oxidation and corrosion.

- Limited ability of producing nuts in the magnet and complicated forms - preferred is a housing - mounting mechanism.

- Potential hazard resulting from small fragments of magnets pose a threat, if swallowed, which is particularly important in the context of child health protection. Additionally, small components of these devices are able to disrupt the diagnostic process medical after entering the body.

- Due to neodymium price, their price exceeds standard values,

Lifting parameters

Highest magnetic holding force – what contributes to it?

- on a base made of structural steel, perfectly concentrating the magnetic flux

- with a cross-section of at least 10 mm

- with a surface free of scratches

- with total lack of distance (no impurities)

- under perpendicular force vector (90-degree angle)

- at conditions approx. 20°C

Lifting capacity in real conditions – factors

- Space between surfaces – every millimeter of distance (caused e.g. by veneer or unevenness) diminishes the pulling force, often by half at just 0.5 mm.

- Pull-off angle – remember that the magnet holds strongest perpendicularly. Under shear forces, the capacity drops significantly, often to levels of 20-30% of the nominal value.

- Plate thickness – too thin sheet causes magnetic saturation, causing part of the flux to be escaped into the air.

- Material type – ideal substrate is pure iron steel. Hardened steels may attract less.

- Surface quality – the smoother and more polished the surface, the larger the contact zone and stronger the hold. Roughness acts like micro-gaps.

- Thermal factor – high temperature reduces magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity testing was conducted on a smooth plate of suitable thickness, under perpendicular forces, in contrast under attempts to slide the magnet the holding force is lower. Additionally, even a minimal clearance between the magnet’s surface and the plate decreases the holding force.

Life threat

Warning for patients: Strong magnetic fields disrupt electronics. Keep at least 30 cm distance or request help to work with the magnets.

Do not overheat magnets

Avoid heat. Neodymium magnets are sensitive to heat. If you need operation above 80°C, inquire about special high-temperature series (H, SH, UH).

Mechanical processing

Fire warning: Rare earth powder is highly flammable. Avoid machining magnets in home conditions as this may cause fire.

Phone sensors

An intense magnetic field interferes with the operation of compasses in phones and navigation systems. Do not bring magnets close to a smartphone to prevent damaging the sensors.

Avoid contact if allergic

Warning for allergy sufferers: The Ni-Cu-Ni coating consists of nickel. If skin irritation occurs, immediately stop working with magnets and use protective gear.

Physical harm

Big blocks can break fingers in a fraction of a second. Never place your hand between two attracting surfaces.

Magnetic media

Avoid bringing magnets near a purse, computer, or screen. The magnetism can destroy these devices and erase data from cards.

Protective goggles

Protect your eyes. Magnets can fracture upon violent connection, ejecting sharp fragments into the air. We recommend safety glasses.

Do not give to children

These products are not suitable for play. Eating a few magnets may result in them attracting across intestines, which poses a severe health hazard and necessitates urgent medical intervention.

Safe operation

Handle with care. Rare earth magnets attract from a distance and connect with massive power, often faster than you can move away.