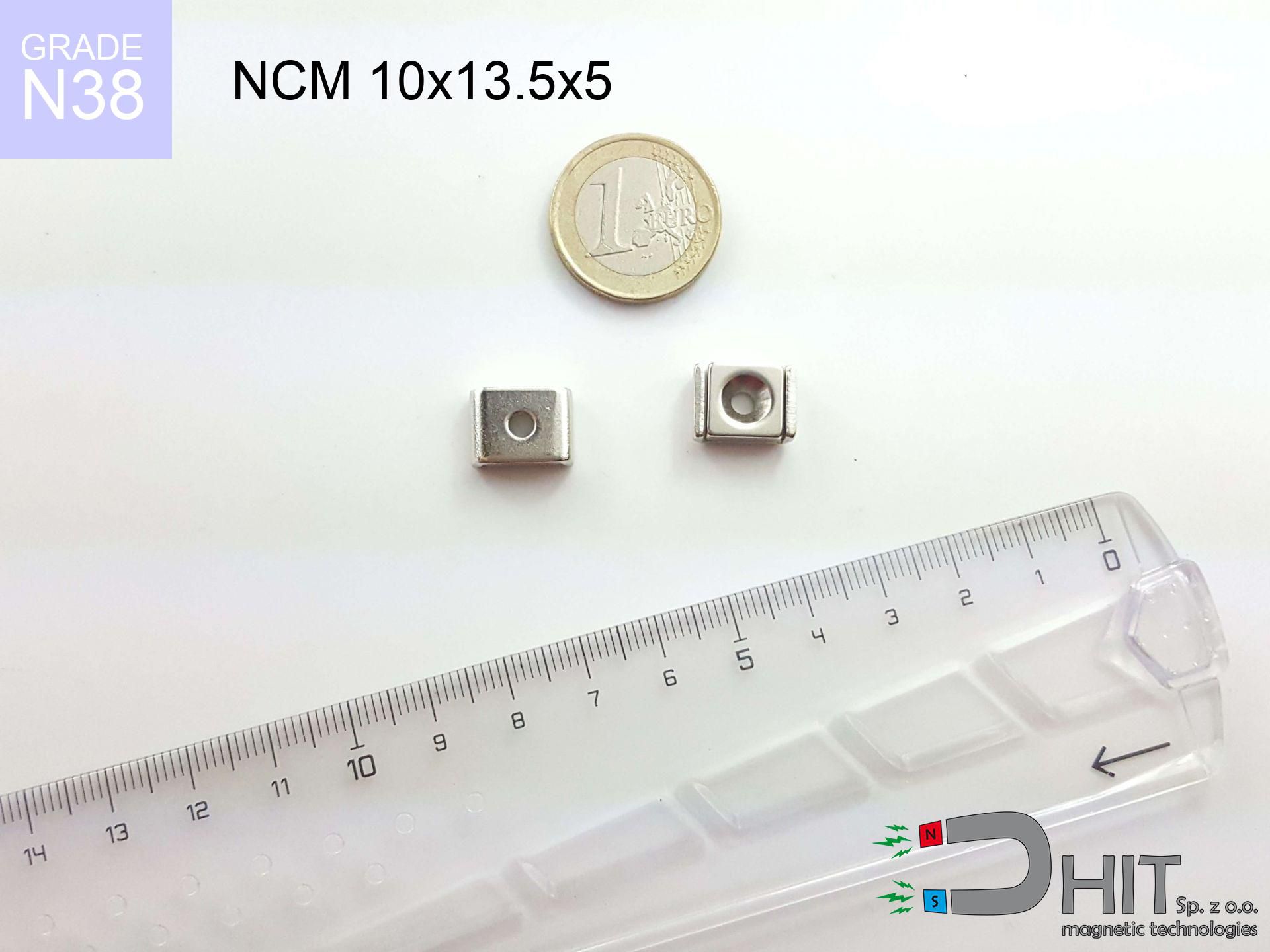

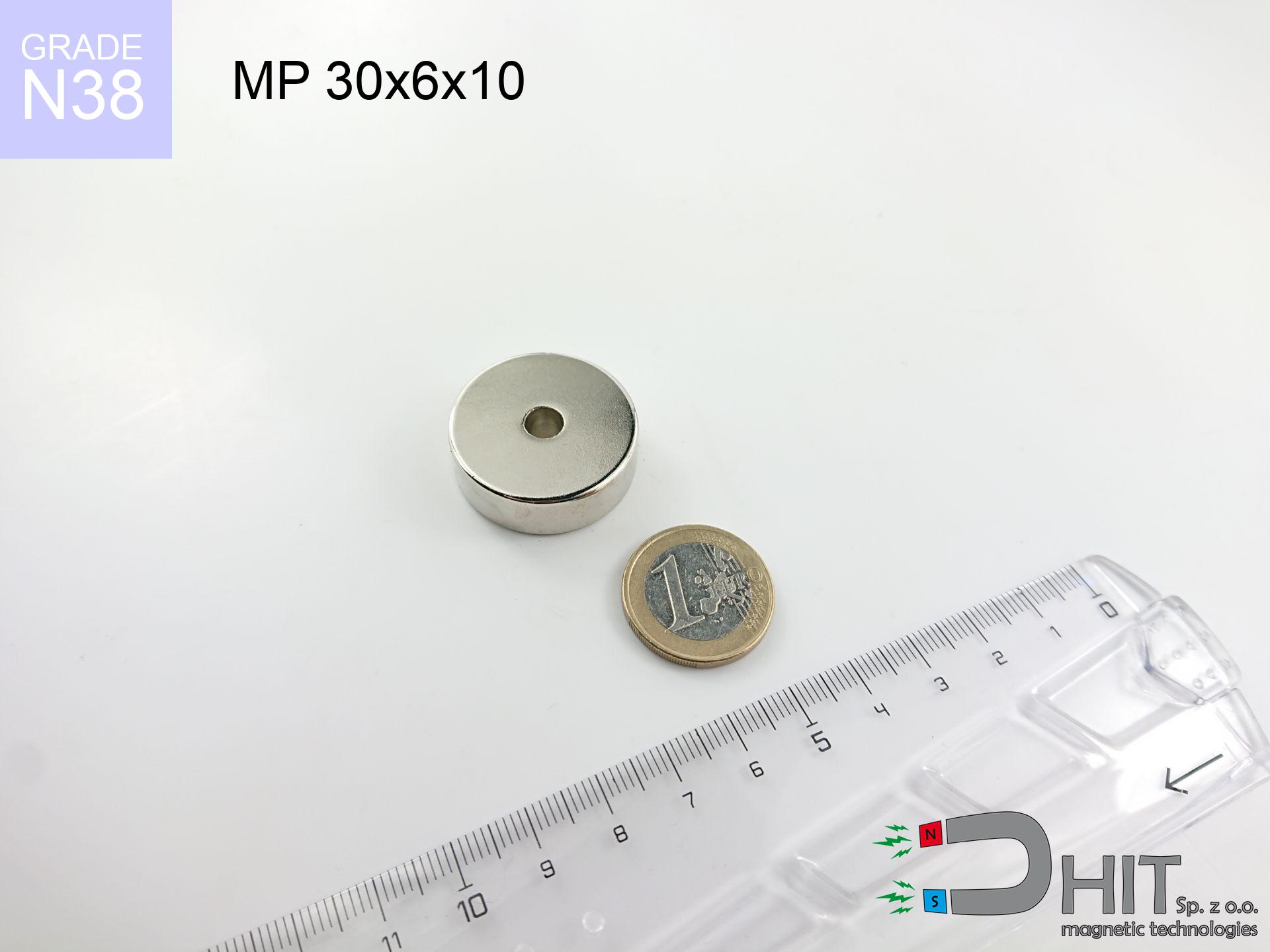

UMGZ 20x15x7 [M4] GZ / N38 - magnetic holder external thread

magnetic holder external thread

Catalog no 190322

GTIN: 5906301813811

Diameter Ø [±0,1 mm]

20 mm

Height [±0,1 mm]

15 mm

Height [±0,1 mm]

7 mm

Weight

14 g

Load capacity

9 kg / 88.26 N

7.22 ZŁ with VAT / pcs + price for transport

5.87 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?Looking for a better price?

Contact us by phone

+48 888 99 98 98

or contact us via

inquiry form

the contact form page.

Weight and shape of neodymium magnets can be estimated with our

power calculator.

Same-day processing for orders placed before 14:00.

Magnetic properties of material N38

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

Shopping tips

Advantages and disadvantages of neodymium magnets.

Besides their magnetic performance, neodymium magnets are valued for these benefits:

- They retain magnetic properties for nearly 10 years – the loss is just ~1% (in theory),

- They maintain their magnetic properties even under external field action,

- A magnet with a metallic nickel surface has better aesthetics,

- The surface of neodymium magnets generates a intense magnetic field – this is a key feature,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the form) even at high temperatures reaching 230°C or more...

- Possibility of detailed modeling and optimizing to precise needs,

- Significant place in advanced technology sectors – they serve a role in data components, motor assemblies, diagnostic systems, as well as modern systems.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Disadvantages of neodymium magnets:

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can break. We recommend keeping them in a strong case, which not only protects them against impacts but also raises their durability

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- They oxidize in a humid environment. For use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- We suggest a housing - magnetic mechanism, due to difficulties in creating threads inside the magnet and complex forms.

- Potential hazard resulting from small fragments of magnets pose a threat, in case of ingestion, which gains importance in the context of child health protection. It is also worth noting that small elements of these magnets can complicate diagnosis medical after entering the body.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Detachment force of the magnet in optimal conditions – what contributes to it?

Magnet power was defined for ideal contact conditions, taking into account:

- on a base made of structural steel, perfectly concentrating the magnetic field

- with a cross-section of at least 10 mm

- with a plane free of scratches

- under conditions of gap-free contact (surface-to-surface)

- under perpendicular force vector (90-degree angle)

- at conditions approx. 20°C

Magnet lifting force in use – key factors

Holding efficiency impacted by specific conditions, mainly (from most important):

- Distance (between the magnet and the plate), because even a tiny clearance (e.g. 0.5 mm) can cause a decrease in force by up to 50% (this also applies to varnish, corrosion or debris).

- Pull-off angle – remember that the magnet holds strongest perpendicularly. Under shear forces, the capacity drops significantly, often to levels of 20-30% of the maximum value.

- Metal thickness – the thinner the sheet, the weaker the hold. Magnetic flux passes through the material instead of generating force.

- Steel grade – ideal substrate is high-permeability steel. Hardened steels may attract less.

- Smoothness – full contact is possible only on polished steel. Any scratches and bumps reduce the real contact area, weakening the magnet.

- Heat – neodymium magnets have a sensitivity to temperature. At higher temperatures they lose power, and in frost gain strength (up to a certain limit).

* Holding force was measured on the plate surface of 20 mm thickness, when the force acted perpendicularly, however under attempts to slide the magnet the holding force is lower. In addition, even a small distance {between} the magnet’s surface and the plate reduces the holding force.

Warnings

Magnetic media

Avoid bringing magnets close to a wallet, laptop, or screen. The magnetic field can irreversibly ruin these devices and erase data from cards.

Magnets are brittle

Despite the nickel coating, the material is delicate and cannot withstand shocks. Do not hit, as the magnet may shatter into sharp, dangerous pieces.

Allergy Warning

It is widely known that the nickel plating (standard magnet coating) is a potent allergen. If you have an allergy, avoid direct skin contact or opt for coated magnets.

Finger safety

Pinching hazard: The attraction force is so immense that it can result in hematomas, crushing, and even bone fractures. Use thick gloves.

Conscious usage

Before starting, check safety instructions. Uncontrolled attraction can break the magnet or injure your hand. Think ahead.

Warning for heart patients

Patients with a pacemaker should maintain an large gap from magnets. The magnetism can disrupt the functioning of the life-saving device.

GPS and phone interference

Note: rare earth magnets produce a field that interferes with precision electronics. Maintain a separation from your mobile, device, and navigation systems.

Keep away from children

These products are not toys. Swallowing several magnets can lead to them pinching intestinal walls, which poses a severe health hazard and requires urgent medical intervention.

Operating temperature

Standard neodymium magnets (N-type) lose magnetization when the temperature goes above 80°C. The loss of strength is permanent.

Machining danger

Fire hazard: Neodymium dust is explosive. Avoid machining magnets without safety gear as this risks ignition.

Danger!

Details about hazards in the article: Magnet Safety Guide.

![Magnet with screw UMGZ 20x15x7 [M4] GZ / N38 Magnet with screw UMGZ 20x15x7 [M4] GZ / N38](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![UMGZ 20x15x7 [M4] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/um-20x15x7-m4-gz-vaf.jpg)

![UMGZ 20x15x7 [M4] GZ / N38 - magnetic holder external thread - ujęcie 2](https://cdn3.dhit.pl/graphics/products/umgw-20x15x7-m4-gz-jeb.jpg)

![SM 32x275 [2xM8] / N42 - magnetic separator SM 32x275 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x275-2xm8-hac.jpg)