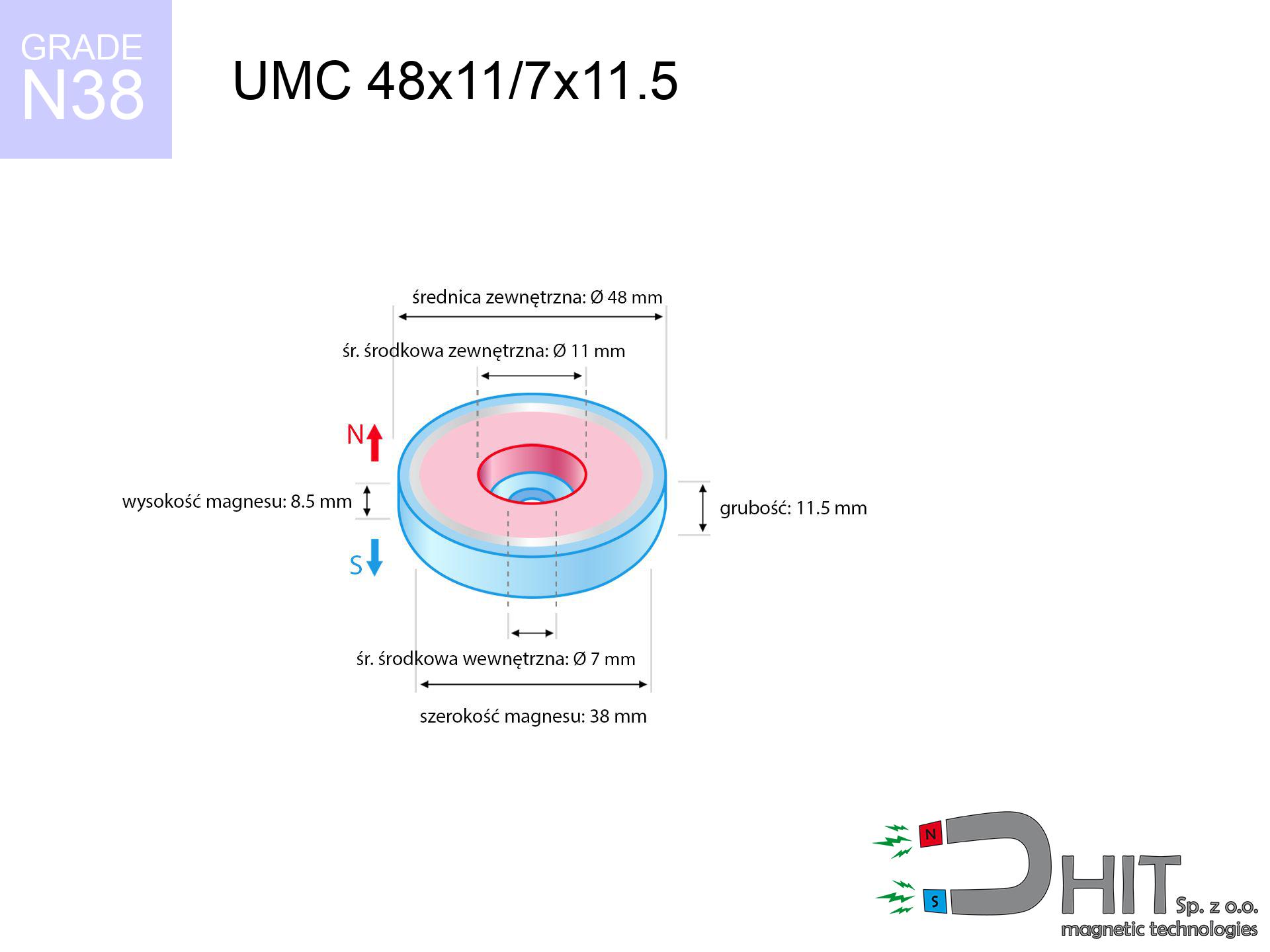

UMC 48x11/7x11.5 / N38 - cylindrical magnetic holder

cylindrical magnetic holder

Catalog no 320412

GTIN/EAN: 5906301814689

Diameter

48 mm [±1 mm]

internal diameter Ø

11/7 mm [±1 mm]

Height

11.5 mm [±1 mm]

Weight

114 g

Load capacity

63.00 kg / 617.82 N

Coating

[NiCuNi] Nickel

45.10 ZŁ with VAT / pcs + price for transport

36.67 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

if you prefer contact us by means of

form

through our site.

Weight along with appearance of magnets can be tested using our

magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Detailed specification - UMC 48x11/7x11.5 / N38 - cylindrical magnetic holder

Specification / characteristics - UMC 48x11/7x11.5 / N38 - cylindrical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 320412 |

| GTIN/EAN | 5906301814689 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 48 mm [±1 mm] |

| internal diameter Ø | 11/7 mm [±1 mm] |

| Height | 11.5 mm [±1 mm] |

| Weight | 114 g |

| Load capacity ~ ? | 63.00 kg / 617.82 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Pros as well as cons of neodymium magnets.

Benefits

- They retain attractive force for almost 10 years – the drop is just ~1% (in theory),

- Neodymium magnets are distinguished by extremely resistant to demagnetization caused by external field sources,

- Thanks to the shiny finish, the surface of Ni-Cu-Ni, gold-plated, or silver-plated gives an elegant appearance,

- The surface of neodymium magnets generates a intense magnetic field – this is one of their assets,

- Thanks to resistance to high temperature, they are able to function (depending on the form) even at temperatures up to 230°C and higher...

- Thanks to versatility in constructing and the ability to modify to client solutions,

- Universal use in modern technologies – they are utilized in HDD drives, electric drive systems, precision medical tools, also complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer high power in small dimensions, which enables their usage in miniature devices

Cons

- To avoid cracks upon strong impacts, we suggest using special steel holders. Such a solution protects the magnet and simultaneously increases its durability.

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Magnets exposed to a humid environment can corrode. Therefore while using outdoors, we suggest using waterproof magnets made of rubber, plastic or other material resistant to moisture

- Due to limitations in realizing threads and complex forms in magnets, we propose using a housing - magnetic holder.

- Potential hazard resulting from small fragments of magnets pose a threat, if swallowed, which becomes key in the aspect of protecting the youngest. Additionally, small elements of these magnets can disrupt the diagnostic process medical after entering the body.

- With large orders the cost of neodymium magnets is economically unviable,

Pull force analysis

Magnetic strength at its maximum – what contributes to it?

- with the use of a sheet made of low-carbon steel, ensuring maximum field concentration

- possessing a massiveness of min. 10 mm to ensure full flux closure

- with a surface free of scratches

- with direct contact (no impurities)

- for force acting at a right angle (in the magnet axis)

- at ambient temperature approx. 20 degrees Celsius

Key elements affecting lifting force

- Clearance – the presence of any layer (paint, dirt, gap) interrupts the magnetic circuit, which reduces power rapidly (even by 50% at 0.5 mm).

- Loading method – declared lifting capacity refers to pulling vertically. When applying parallel force, the magnet exhibits significantly lower power (typically approx. 20-30% of maximum force).

- Plate thickness – too thin plate causes magnetic saturation, causing part of the flux to be escaped into the air.

- Material type – ideal substrate is pure iron steel. Stainless steels may have worse magnetic properties.

- Smoothness – ideal contact is obtained only on polished steel. Rough texture create air cushions, weakening the magnet.

- Thermal conditions – NdFeB sinters have a sensitivity to temperature. When it is hot they lose power, and at low temperatures gain strength (up to a certain limit).

Lifting capacity testing was carried out on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, in contrast under shearing force the load capacity is reduced by as much as 75%. Moreover, even a small distance between the magnet’s surface and the plate lowers the load capacity.

H&S for magnets

Health Danger

Warning for patients: Strong magnetic fields disrupt electronics. Keep minimum 30 cm distance or request help to work with the magnets.

Handling rules

Handle magnets consciously. Their powerful strength can shock even professionals. Plan your moves and respect their force.

Pinching danger

Watch your fingers. Two powerful magnets will join instantly with a force of several hundred kilograms, destroying everything in their path. Be careful!

Demagnetization risk

Watch the temperature. Exposing the magnet above 80 degrees Celsius will permanently weaken its properties and pulling force.

Do not give to children

Absolutely store magnets out of reach of children. Choking hazard is high, and the effects of magnets clamping inside the body are very dangerous.

Machining danger

Powder generated during machining of magnets is combustible. Avoid drilling into magnets unless you are an expert.

Protect data

Powerful magnetic fields can erase data on credit cards, HDDs, and other magnetic media. Keep a distance of at least 10 cm.

Avoid contact if allergic

Certain individuals have a hypersensitivity to nickel, which is the standard coating for neodymium magnets. Prolonged contact can result in an allergic reaction. We suggest use protective gloves.

GPS Danger

GPS units and smartphones are extremely susceptible to magnetic fields. Close proximity with a powerful NdFeB magnet can ruin the internal compass in your phone.

Shattering risk

NdFeB magnets are ceramic materials, which means they are very brittle. Impact of two magnets will cause them shattering into shards.

![UMP 107x40 [M8+M10] GW F 400 kg / N38 - search holder UMP 107x40 [M8+M10] GW F 400 kg / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump107x40-m8+m10-gw-f-400-kg-mup.jpg)

![MPL 40x15x5x2[7/3.5] / N38 - lamellar magnet MPL 40x15x5x2[7/3.5] / N38 - lamellar magnet](https://cdn3.dhit.pl/graphics/products/mpl-40x15x5x27-3.5-cas.jpg)

![AM szekla [M10] - magnetic accessories AM szekla [M10] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-szekla-m10-zeh.jpg)