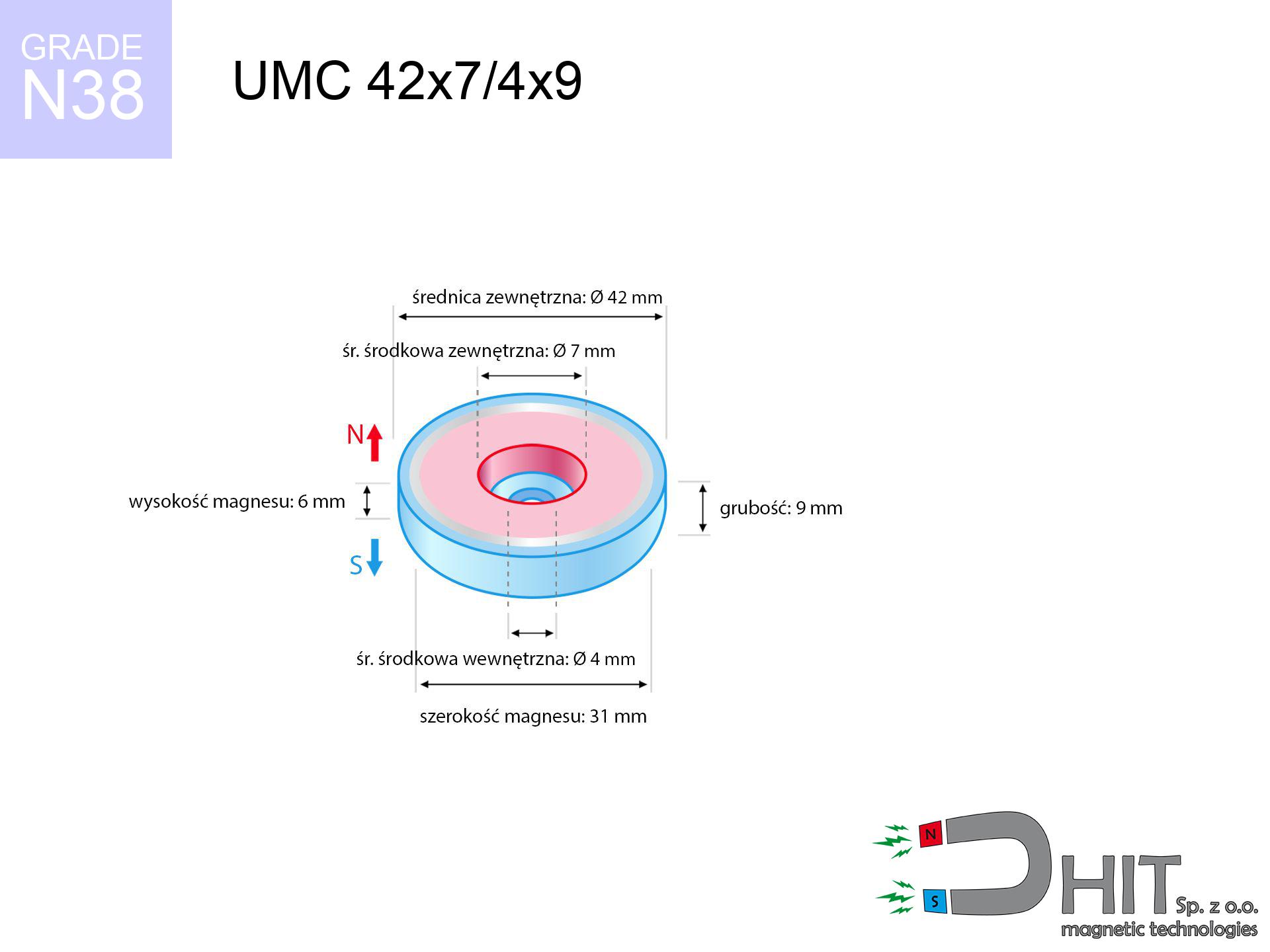

UMC 42x7/4x9 / N38 - cylindrical magnetic holder

cylindrical magnetic holder

Catalog no 320411

GTIN/EAN: 5906301814672

Diameter

42 mm [±1 mm]

internal diameter Ø

7/4 mm [±1 mm]

Height

9 mm [±1 mm]

Weight

72 g

Load capacity

32.00 kg / 313.81 N

Coating

[NiCuNi] Nickel

29.99 ZŁ with VAT / pcs + price for transport

24.38 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

or send us a note via

form

our website.

Weight and structure of neodymium magnets can be calculated using our

force calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical parameters - UMC 42x7/4x9 / N38 - cylindrical magnetic holder

Specification / characteristics - UMC 42x7/4x9 / N38 - cylindrical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 320411 |

| GTIN/EAN | 5906301814672 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 42 mm [±1 mm] |

| internal diameter Ø | 7/4 mm [±1 mm] |

| Height | 9 mm [±1 mm] |

| Weight | 72 g |

| Load capacity ~ ? | 32.00 kg / 313.81 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also products

Strengths as well as weaknesses of Nd2Fe14B magnets.

Benefits

- They retain magnetic properties for almost ten years – the loss is just ~1% (based on simulations),

- They possess excellent resistance to magnetic field loss when exposed to external fields,

- By using a reflective layer of nickel, the element gains an nice look,

- The surface of neodymium magnets generates a strong magnetic field – this is one of their assets,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Due to the ability of flexible forming and customization to specialized needs, neodymium magnets can be manufactured in a variety of geometric configurations, which amplifies use scope,

- Fundamental importance in electronics industry – they are commonly used in magnetic memories, electric motors, medical devices, and modern systems.

- Thanks to concentrated force, small magnets offer high operating force, in miniature format,

Weaknesses

- To avoid cracks under impact, we suggest using special steel housings. Such a solution secures the magnet and simultaneously improves its durability.

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- They oxidize in a humid environment. For use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- We recommend casing - magnetic mount, due to difficulties in realizing nuts inside the magnet and complex shapes.

- Health risk related to microscopic parts of magnets can be dangerous, if swallowed, which is particularly important in the context of child safety. Additionally, small components of these devices are able to disrupt the diagnostic process medical after entering the body.

- Due to complex production process, their price exceeds standard values,

Lifting parameters

Maximum holding power of the magnet – what it depends on?

- with the use of a yoke made of low-carbon steel, guaranteeing full magnetic saturation

- possessing a thickness of minimum 10 mm to avoid saturation

- characterized by even structure

- without any insulating layer between the magnet and steel

- during detachment in a direction perpendicular to the mounting surface

- in stable room temperature

Determinants of lifting force in real conditions

- Space between magnet and steel – every millimeter of distance (caused e.g. by veneer or dirt) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Direction of force – highest force is obtained only during pulling at a 90° angle. The shear force of the magnet along the surface is usually many times smaller (approx. 1/5 of the lifting capacity).

- Metal thickness – thin material does not allow full use of the magnet. Magnetic flux passes through the material instead of generating force.

- Material type – ideal substrate is high-permeability steel. Stainless steels may generate lower lifting capacity.

- Surface condition – ground elements guarantee perfect abutment, which improves force. Uneven metal weaken the grip.

- Temperature – heating the magnet causes a temporary drop of force. It is worth remembering the thermal limit for a given model.

Lifting capacity was measured by applying a steel plate with a smooth surface of suitable thickness (min. 20 mm), under perpendicular detachment force, however under attempts to slide the magnet the load capacity is reduced by as much as fivefold. Additionally, even a minimal clearance between the magnet’s surface and the plate decreases the load capacity.

Warnings

No play value

Always keep magnets away from children. Risk of swallowing is high, and the consequences of magnets clamping inside the body are tragic.

Phone sensors

A powerful magnetic field negatively affects the functioning of compasses in smartphones and navigation systems. Do not bring magnets close to a smartphone to avoid breaking the sensors.

Beware of splinters

Beware of splinters. Magnets can explode upon violent connection, ejecting shards into the air. Wear goggles.

Electronic hazard

Powerful magnetic fields can corrupt files on payment cards, HDDs, and storage devices. Keep a distance of min. 10 cm.

Conscious usage

Be careful. Rare earth magnets attract from a long distance and connect with huge force, often faster than you can react.

Life threat

For implant holders: Powerful magnets affect electronics. Maintain minimum 30 cm distance or ask another person to work with the magnets.

Do not drill into magnets

Dust created during cutting of magnets is flammable. Do not drill into magnets unless you are an expert.

Power loss in heat

Standard neodymium magnets (grade N) undergo demagnetization when the temperature exceeds 80°C. This process is irreversible.

Bone fractures

Watch your fingers. Two powerful magnets will snap together immediately with a force of several hundred kilograms, crushing everything in their path. Be careful!

Avoid contact if allergic

Allergy Notice: The Ni-Cu-Ni coating contains nickel. If skin irritation happens, immediately stop handling magnets and use protective gear.

![UMH 36x8x46 [M6] / N38 - magnetic holder with hook UMH 36x8x46 [M6] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-36x8x46-m6-wim.jpg)

![SM 25x225 [2xM8] / N42 - magnetic separator SM 25x225 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x225-2xm8-tix.jpg)

![UMGZ 16x13x5 [M4] GZ / N38 - magnetic holder external thread UMGZ 16x13x5 [M4] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/um-16x13x5-m4-gz-cor.jpg)