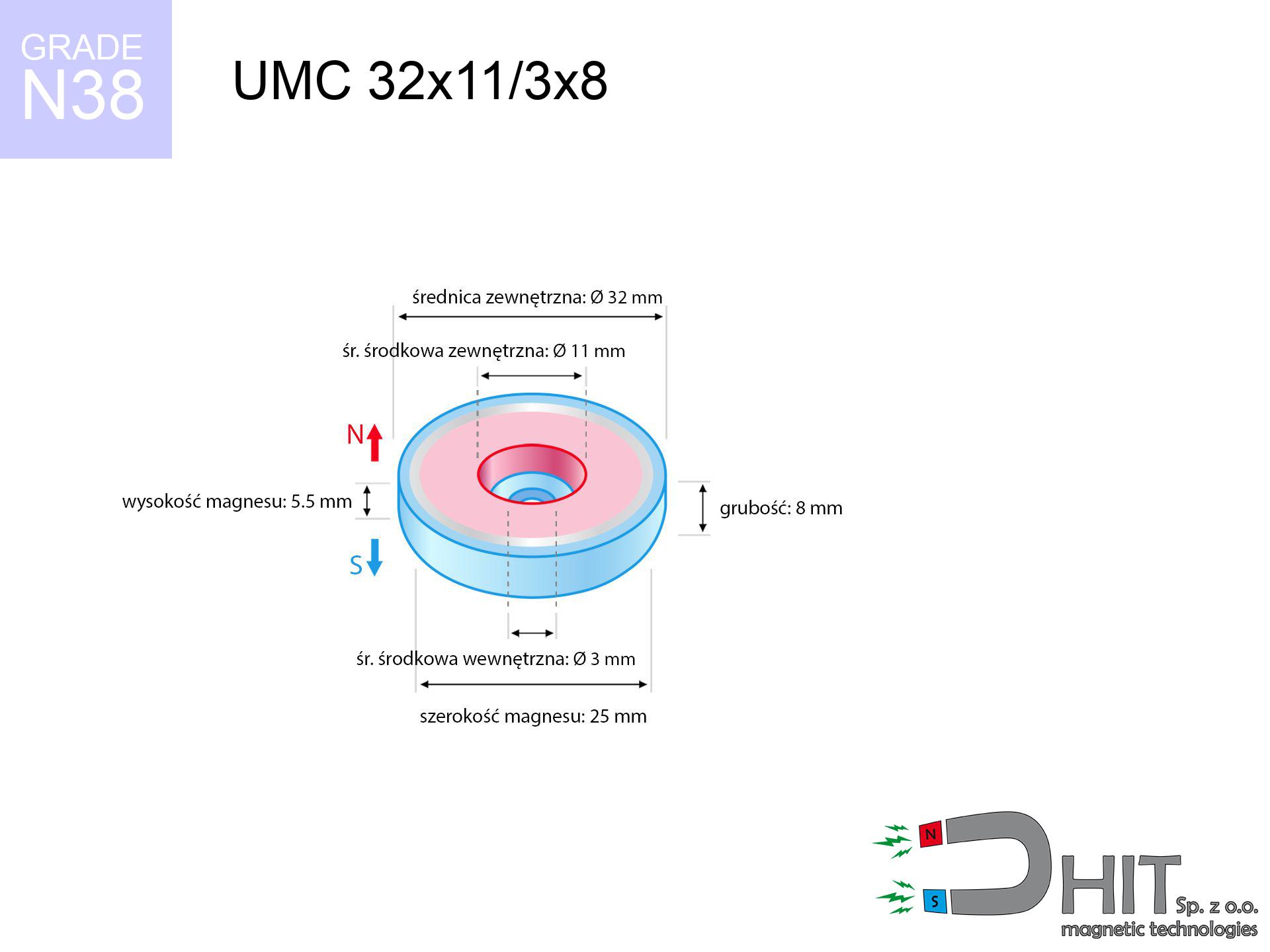

UMC 32x11/3x8 / N38 - cylindrical magnetic holder

cylindrical magnetic holder

Catalog no 320409

GTIN/EAN: 5906301814658

Diameter

32 mm [±1 mm]

internal diameter Ø

11/3 mm [±1 mm]

Height

8 mm [±1 mm]

Weight

36 g

Load capacity

23.00 kg / 225.55 N

Coating

[NiCuNi] Nickel

17.98 ZŁ with VAT / pcs + price for transport

14.62 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

or let us know via

contact form

the contact page.

Lifting power along with shape of a magnet can be analyzed on our

modular calculator.

Orders submitted before 14:00 will be dispatched today!

Physical properties - UMC 32x11/3x8 / N38 - cylindrical magnetic holder

Specification / characteristics - UMC 32x11/3x8 / N38 - cylindrical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 320409 |

| GTIN/EAN | 5906301814658 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 32 mm [±1 mm] |

| internal diameter Ø | 11/3 mm [±1 mm] |

| Height | 8 mm [±1 mm] |

| Weight | 36 g |

| Load capacity ~ ? | 23.00 kg / 225.55 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Advantages as well as disadvantages of Nd2Fe14B magnets.

Advantages

- They have unchanged lifting capacity, and over around ten years their performance decreases symbolically – ~1% (in testing),

- Neodymium magnets prove to be extremely resistant to loss of magnetic properties caused by external field sources,

- By using a decorative layer of gold, the element gains an modern look,

- Magnetic induction on the top side of the magnet turns out to be extremely intense,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can work (depending on the shape) even at a temperature of 230°C or more...

- Possibility of individual shaping as well as adjusting to precise needs,

- Key role in advanced technology sectors – they serve a role in magnetic memories, drive modules, diagnostic systems, as well as industrial machines.

- Thanks to concentrated force, small magnets offer high operating force, occupying minimum space,

Disadvantages

- Brittleness is one of their disadvantages. Upon strong impact they can fracture. We recommend keeping them in a special holder, which not only protects them against impacts but also raises their durability

- Neodymium magnets decrease their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture, in case of application outdoors

- Due to limitations in realizing threads and complex forms in magnets, we recommend using a housing - magnetic holder.

- Health risk to health – tiny shards of magnets are risky, in case of ingestion, which gains importance in the aspect of protecting the youngest. Furthermore, small elements of these products are able to complicate diagnosis medical when they are in the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Pull force analysis

Highest magnetic holding force – what it depends on?

- with the contact of a sheet made of special test steel, ensuring full magnetic saturation

- possessing a thickness of min. 10 mm to ensure full flux closure

- characterized by even structure

- without the slightest clearance between the magnet and steel

- during pulling in a direction vertical to the plane

- in stable room temperature

Practical aspects of lifting capacity – factors

- Distance (between the magnet and the plate), as even a microscopic distance (e.g. 0.5 mm) can cause a drastic drop in force by up to 50% (this also applies to varnish, rust or debris).

- Angle of force application – maximum parameter is obtained only during pulling at a 90° angle. The force required to slide of the magnet along the plate is standardly many times lower (approx. 1/5 of the lifting capacity).

- Element thickness – to utilize 100% power, the steel must be sufficiently thick. Thin sheet restricts the lifting capacity (the magnet "punches through" it).

- Plate material – low-carbon steel attracts best. Alloy steels lower magnetic properties and holding force.

- Base smoothness – the more even the plate, the better the adhesion and stronger the hold. Unevenness creates an air distance.

- Thermal environment – heating the magnet results in weakening of induction. It is worth remembering the thermal limit for a given model.

Lifting capacity testing was carried out on plates with a smooth surface of optimal thickness, under a perpendicular pulling force, whereas under shearing force the lifting capacity is smaller. In addition, even a minimal clearance between the magnet’s surface and the plate decreases the holding force.

Warnings

Pacemakers

Warning for patients: Powerful magnets affect electronics. Keep at least 30 cm distance or ask another person to handle the magnets.

Data carriers

Do not bring magnets close to a purse, laptop, or TV. The magnetism can irreversibly ruin these devices and wipe information from cards.

Serious injuries

Big blocks can break fingers instantly. Do not put your hand betwixt two strong magnets.

Sensitization to coating

Warning for allergy sufferers: The nickel-copper-nickel coating consists of nickel. If an allergic reaction happens, cease handling magnets and wear gloves.

Demagnetization risk

Control the heat. Exposing the magnet above 80 degrees Celsius will permanently weaken its magnetic structure and strength.

No play value

These products are not toys. Swallowing a few magnets may result in them attracting across intestines, which constitutes a severe health hazard and necessitates urgent medical intervention.

Do not drill into magnets

Machining of neodymium magnets carries a risk of fire hazard. Magnetic powder oxidizes rapidly with oxygen and is hard to extinguish.

Powerful field

Before starting, read the rules. Uncontrolled attraction can break the magnet or injure your hand. Be predictive.

Shattering risk

Despite metallic appearance, neodymium is brittle and not impact-resistant. Do not hit, as the magnet may shatter into hazardous fragments.

Threat to navigation

Note: neodymium magnets produce a field that confuses precision electronics. Maintain a separation from your mobile, tablet, and navigation systems.

![UMGW 20x15x7 [M4] GW / N38 - magnetic holder internal thread UMGW 20x15x7 [M4] GW / N38 - magnetic holder internal thread](https://cdn3.dhit.pl/graphics/products/um-20x15x7-m4-gw-big.jpg)

![SM 32x300 [2xM8] / N42 - magnetic separator SM 32x300 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x300-2xm8-pel.jpg)