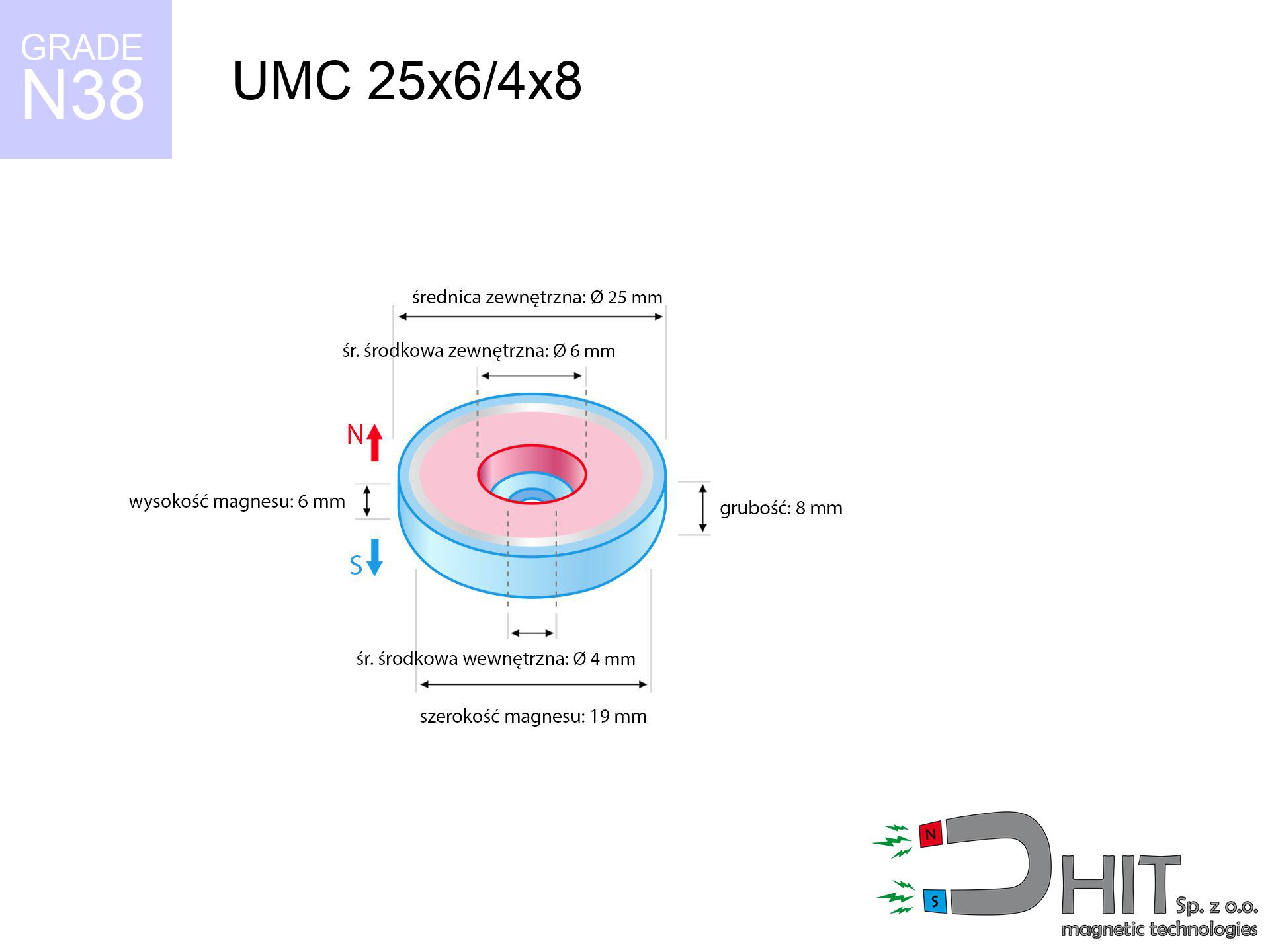

UMC 25x6/4x8 / N38 - cylindrical magnetic holder

cylindrical magnetic holder

Catalog no 320408

GTIN/EAN: 5906301814641

Diameter

25 mm [±1 mm]

internal diameter Ø

6/4 mm [±1 mm]

Height

8 mm [±1 mm]

Weight

21 g

Load capacity

14.00 kg / 137.29 N

Coating

[NiCuNi] Nickel

11.70 ZŁ with VAT / pcs + price for transport

9.51 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

otherwise send us a note through

our online form

the contact page.

Strength as well as shape of neodymium magnets can be analyzed on our

modular calculator.

Order by 14:00 and we’ll ship today!

Technical data - UMC 25x6/4x8 / N38 - cylindrical magnetic holder

Specification / characteristics - UMC 25x6/4x8 / N38 - cylindrical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 320408 |

| GTIN/EAN | 5906301814641 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 25 mm [±1 mm] |

| internal diameter Ø | 6/4 mm [±1 mm] |

| Height | 8 mm [±1 mm] |

| Weight | 21 g |

| Load capacity ~ ? | 14.00 kg / 137.29 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also deals

Pros as well as cons of neodymium magnets.

Advantages

- They virtually do not lose strength, because even after 10 years the decline in efficiency is only ~1% (according to literature),

- They are noted for resistance to demagnetization induced by external disturbances,

- In other words, due to the aesthetic layer of silver, the element looks attractive,

- Magnets possess impressive magnetic induction on the active area,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can work (depending on the form) even at a temperature of 230°C or more...

- Thanks to flexibility in designing and the ability to adapt to specific needs,

- Wide application in modern industrial fields – they are used in HDD drives, electric motors, advanced medical instruments, as well as industrial machines.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which enables their usage in miniature devices

Cons

- Brittleness is one of their disadvantages. Upon intense impact they can break. We recommend keeping them in a strong case, which not only secures them against impacts but also raises their durability

- Neodymium magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Magnets exposed to a humid environment can corrode. Therefore when using outdoors, we recommend using waterproof magnets made of rubber, plastic or other material resistant to moisture

- Due to limitations in creating threads and complicated shapes in magnets, we propose using a housing - magnetic holder.

- Health risk to health – tiny shards of magnets are risky, if swallowed, which gains importance in the context of child safety. Additionally, small elements of these magnets are able to be problematic in diagnostics medical when they are in the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Pull force analysis

Maximum magnetic pulling force – what contributes to it?

- using a base made of mild steel, serving as a magnetic yoke

- possessing a massiveness of at least 10 mm to avoid saturation

- characterized by lack of roughness

- with total lack of distance (without paint)

- during detachment in a direction perpendicular to the mounting surface

- at temperature approx. 20 degrees Celsius

Impact of factors on magnetic holding capacity in practice

- Gap between surfaces – every millimeter of distance (caused e.g. by varnish or unevenness) diminishes the pulling force, often by half at just 0.5 mm.

- Pull-off angle – remember that the magnet holds strongest perpendicularly. Under sliding down, the holding force drops significantly, often to levels of 20-30% of the nominal value.

- Substrate thickness – for full efficiency, the steel must be sufficiently thick. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Material composition – different alloys attracts identically. High carbon content weaken the interaction with the magnet.

- Surface condition – smooth surfaces ensure maximum contact, which increases force. Uneven metal reduce efficiency.

- Thermal environment – temperature increase causes a temporary drop of force. Check the thermal limit for a given model.

Lifting capacity was measured by applying a steel plate with a smooth surface of suitable thickness (min. 20 mm), under perpendicular pulling force, in contrast under shearing force the load capacity is reduced by as much as 5 times. Additionally, even a minimal clearance between the magnet’s surface and the plate decreases the lifting capacity.

Precautions when working with NdFeB magnets

Health Danger

Life threat: Neodymium magnets can turn off heart devices and defibrillators. Stay away if you have medical devices.

Immense force

Handle magnets with awareness. Their powerful strength can shock even professionals. Be vigilant and respect their power.

Keep away from children

Only for adults. Tiny parts pose a choking risk, causing severe trauma. Keep away from kids and pets.

Warning for allergy sufferers

Nickel alert: The nickel-copper-nickel coating consists of nickel. If an allergic reaction happens, cease working with magnets and wear gloves.

Heat warning

Control the heat. Heating the magnet above 80 degrees Celsius will destroy its magnetic structure and strength.

Finger safety

Watch your fingers. Two powerful magnets will join instantly with a force of massive weight, crushing anything in their path. Be careful!

Impact on smartphones

Navigation devices and mobile phones are extremely sensitive to magnetism. Direct contact with a strong magnet can decalibrate the sensors in your phone.

Mechanical processing

Mechanical processing of NdFeB material poses a fire hazard. Neodymium dust reacts violently with oxygen and is hard to extinguish.

Threat to electronics

Very strong magnetic fields can corrupt files on credit cards, hard drives, and storage devices. Stay away of min. 10 cm.

Eye protection

Protect your eyes. Magnets can fracture upon uncontrolled impact, ejecting sharp fragments into the air. Wear goggles.

![SM 18x150 [2xM5] / N42 - magnetic separator SM 18x150 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x150-2xm5-pec.jpg)