SM 32x375 [2xM8] / N42 - magnetic separator

magnetic separator

Catalog no 130379

GTIN/EAN: 5906301813279

Diameter Ø

32 mm [±1 mm]

Height

375 mm [±1 mm]

Weight

2010 g

Magnetic Flux

~ 8 000 Gauss [±5%]

1119.30 ZŁ with VAT / pcs + price for transport

910.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

alternatively let us know through

our online form

the contact section.

Force along with form of magnets can be tested on our

magnetic mass calculator.

Orders submitted before 14:00 will be dispatched today!

Technical of the product - SM 32x375 [2xM8] / N42 - magnetic separator

Specification / characteristics - SM 32x375 [2xM8] / N42 - magnetic separator

| properties | values |

|---|---|

| Cat. no. | 130379 |

| GTIN/EAN | 5906301813279 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

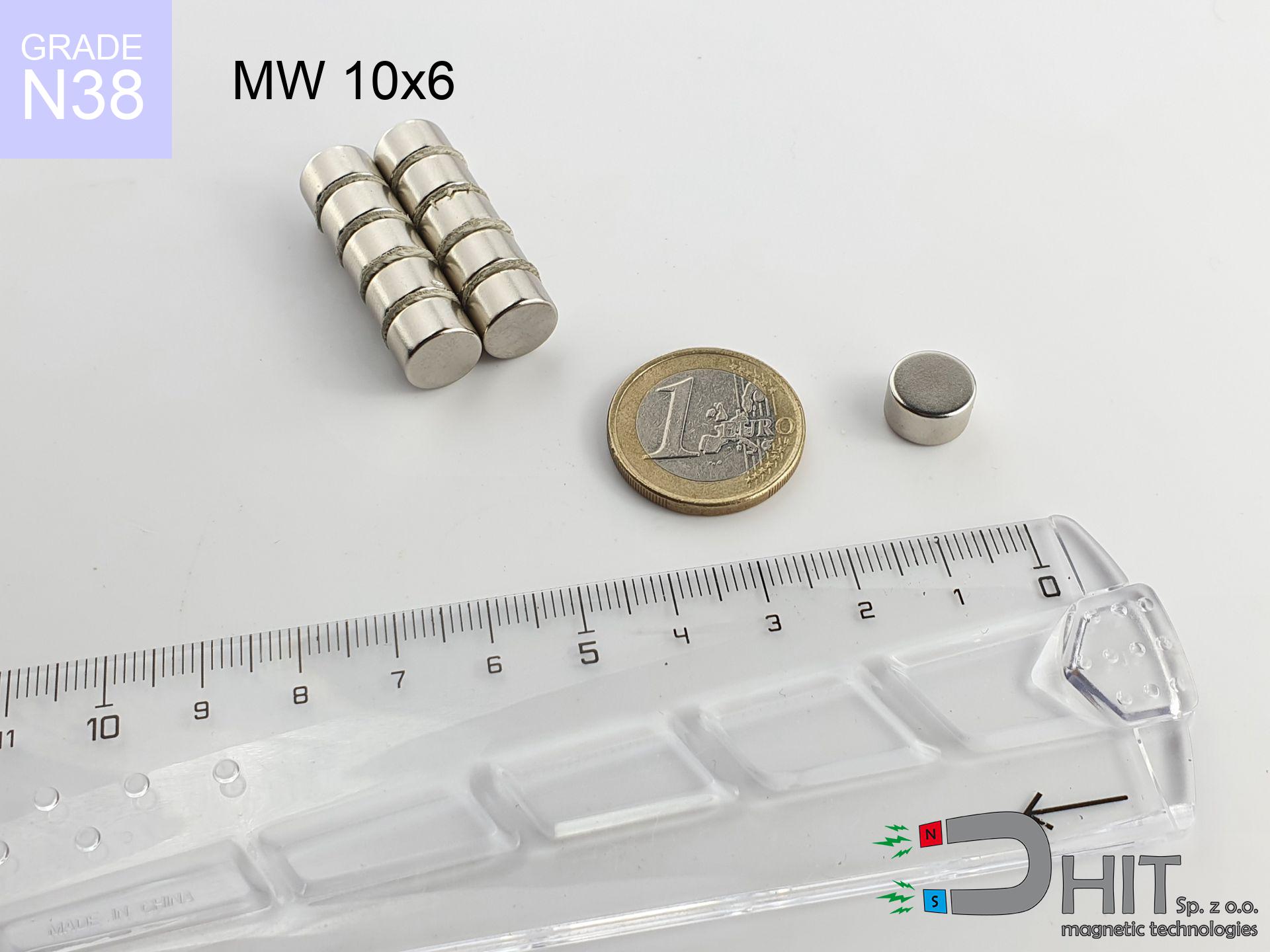

| Diameter Ø | 32 mm [±1 mm] |

| Height | 375 mm [±1 mm] |

| Weight | 2010 g |

| Material Type | Stainless steel AISI 304 / A2 |

| Magnetic Flux | ~ 8 000 Gauss [±5%] |

| Size/Mount Quantity | 2xM8 |

| Polarity | circumferential - 14 poles |

| Casing Tube Thickness | 1 mm |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N42

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.9-13.2 | kGs |

| remenance Br [min. - max.] ? | 1290-1320 | mT |

| coercivity bHc ? | 10.8-12.0 | kOe |

| coercivity bHc ? | 860-955 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 40-42 | BH max MGOe |

| energy density [min. - max.] ? | 318-334 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Table 1: Rod construction

SM 32x375 [2xM8] / N42

| Parameter | Value | Description / Unit |

|---|---|---|

| Diameter (Ø) | 32 | mm |

| Total length | 375 | mm (L) |

| Active length | 339 | mm |

| Section count | 14 | modules |

| Dead zone | 36 | mm (2x 18mm starter) |

| Weight (est.) | ~2292 | g |

| Active area | 341 | cm² (Area) |

| Housing material | AISI 304 | 1.4301 (Inox) |

| Surface finish | Ra < 0.8 µm | Polished |

| Temp. class | 80°C | Standard (N) |

| Force loss (at max °C) | -12.8% | Reversible loss (physics) |

| Force (calculated) | 26.2 | kg (theor.) |

| Induction (surface) | ~8 000 | Gauss (Max) |

Chart 2: Field profile (14 sections)

Chart 3: Temperature performance

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Advantages as well as disadvantages of neodymium magnets.

Benefits

- They virtually do not lose power, because even after ten years the performance loss is only ~1% (in laboratory conditions),

- Magnets very well defend themselves against demagnetization caused by external fields,

- In other words, due to the reflective surface of nickel, the element gains a professional look,

- They feature high magnetic induction at the operating surface, which increases their power,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Possibility of individual machining and adapting to individual applications,

- Wide application in electronics industry – they are used in hard drives, drive modules, advanced medical instruments, also other advanced devices.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Cons

- To avoid cracks under impact, we suggest using special steel holders. Such a solution protects the magnet and simultaneously increases its durability.

- NdFeB magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Magnets exposed to a humid environment can corrode. Therefore while using outdoors, we advise using waterproof magnets made of rubber, plastic or other material protecting against moisture

- Due to limitations in producing nuts and complex forms in magnets, we propose using a housing - magnetic holder.

- Possible danger related to microscopic parts of magnets can be dangerous, in case of ingestion, which becomes key in the context of child health protection. Furthermore, small elements of these products are able to be problematic in diagnostics medical in case of swallowing.

- Due to expensive raw materials, their price is higher than average,

Holding force characteristics

Breakaway strength of the magnet in ideal conditions – what it depends on?

- on a plate made of structural steel, perfectly concentrating the magnetic field

- with a thickness of at least 10 mm

- with an ideally smooth contact surface

- with zero gap (no coatings)

- under perpendicular application of breakaway force (90-degree angle)

- in neutral thermal conditions

Practical lifting capacity: influencing factors

- Space between magnet and steel – even a fraction of a millimeter of distance (caused e.g. by veneer or dirt) significantly weakens the pulling force, often by half at just 0.5 mm.

- Loading method – declared lifting capacity refers to detachment vertically. When attempting to slide, the magnet holds much less (typically approx. 20-30% of maximum force).

- Element thickness – for full efficiency, the steel must be sufficiently thick. Thin sheet limits the lifting capacity (the magnet "punches through" it).

- Material composition – different alloys reacts the same. Alloy additives worsen the interaction with the magnet.

- Surface finish – ideal contact is possible only on smooth steel. Any scratches and bumps reduce the real contact area, weakening the magnet.

- Thermal conditions – neodymium magnets have a sensitivity to temperature. At higher temperatures they are weaker, and in frost they can be stronger (up to a certain limit).

Lifting capacity testing was carried out on plates with a smooth surface of optimal thickness, under perpendicular forces, however under shearing force the lifting capacity is smaller. In addition, even a slight gap between the magnet and the plate decreases the lifting capacity.

Safety rules for work with NdFeB magnets

Dust explosion hazard

Drilling and cutting of neodymium magnets poses a fire risk. Magnetic powder reacts violently with oxygen and is hard to extinguish.

Warning for heart patients

People with a pacemaker should maintain an absolute distance from magnets. The magnetic field can disrupt the functioning of the life-saving device.

Caution required

Before use, check safety instructions. Sudden snapping can break the magnet or injure your hand. Think ahead.

GPS and phone interference

A strong magnetic field negatively affects the functioning of compasses in phones and GPS navigation. Maintain magnets near a smartphone to avoid breaking the sensors.

Demagnetization risk

Monitor thermal conditions. Exposing the magnet to high heat will ruin its properties and pulling force.

Material brittleness

Despite the nickel coating, neodymium is delicate and cannot withstand shocks. Avoid impacts, as the magnet may shatter into sharp, dangerous pieces.

Keep away from children

Adult use only. Small elements pose a choking risk, leading to serious injuries. Store away from children and animals.

Bodily injuries

Large magnets can break fingers instantly. Never place your hand between two attracting surfaces.

Allergy Warning

Certain individuals have a hypersensitivity to nickel, which is the common plating for NdFeB magnets. Prolonged contact might lead to dermatitis. It is best to use safety gloves.

Keep away from computers

Device Safety: Neodymium magnets can ruin data carriers and sensitive devices (heart implants, medical aids, mechanical watches).

![Separation magnetic rod SM 32x375 [2xM8] / N42 Separation magnetic rod SM 32x375 [2xM8] / N42](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![SM 32x375 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x375-2xm8-nif.jpg)

![SM 25x325 [2xM8] / N42 - magnetic separator SM 25x325 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x325-2xm8-man.jpg)