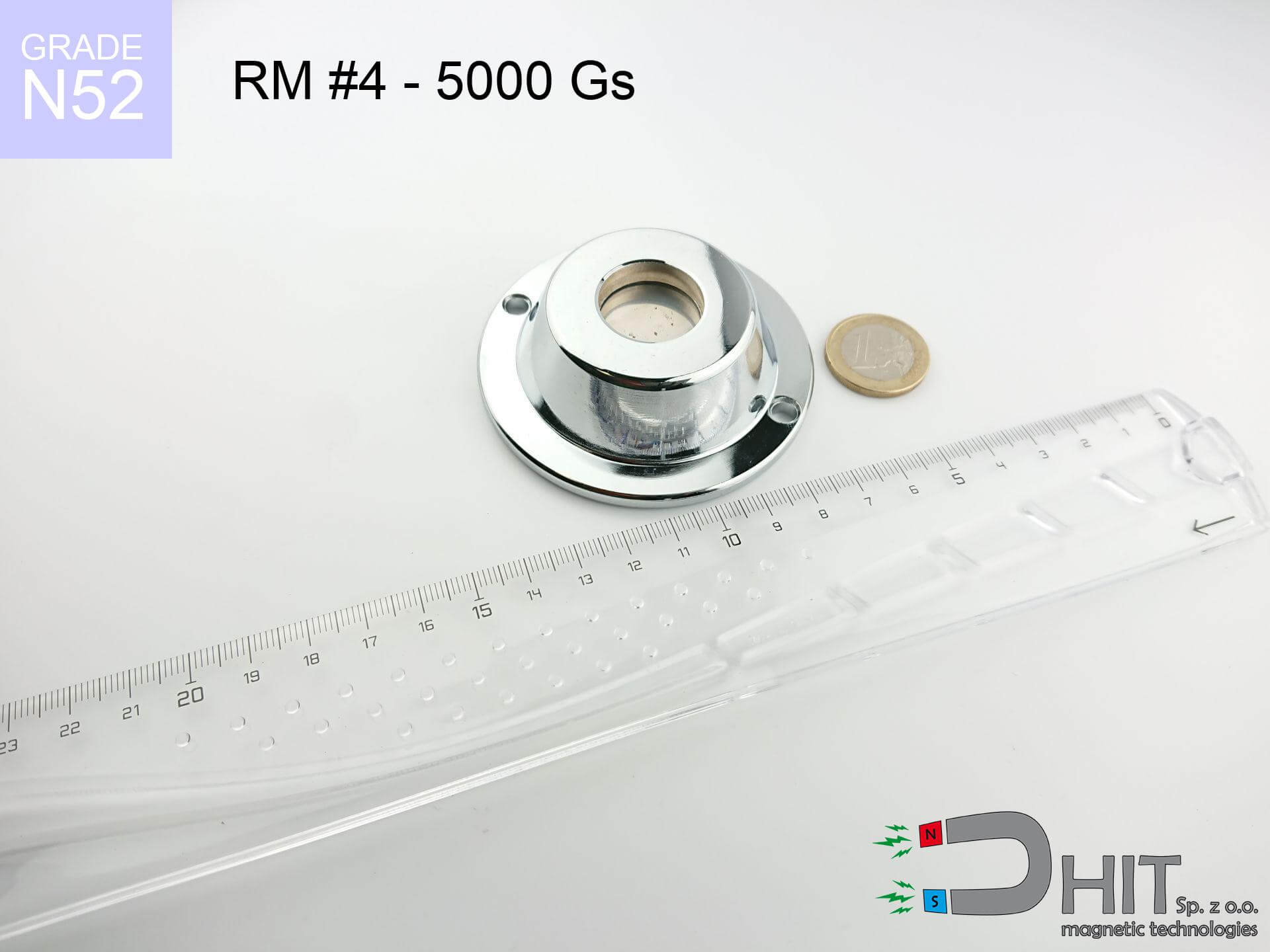

RM R4 - 5000 Gs / N52 - magnetic distributor

magnetic distributor

Catalog no 280254

GTIN/EAN: 5906301814450

Weight

0.01 g

Magnetization Direction

↑ axial

Coating

[NiCuNi] Nickel

66.42 ZŁ with VAT / pcs + price for transport

54.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

or send us a note by means of

inquiry form

our website.

Lifting power and form of a magnet can be tested using our

modular calculator.

Same-day shipping for orders placed before 14:00.

Technical specification of the product - RM R4 - 5000 Gs / N52 - magnetic distributor

Specification / characteristics - RM R4 - 5000 Gs / N52 - magnetic distributor

| properties | values |

|---|---|

| Cat. no. | 280254 |

| GTIN/EAN | 5906301814450 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Weight | 0.01 g |

| Magnetization Direction | ↑ axial |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N52

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 14.2-14.7 | kGs |

| remenance Br [min. - max.] ? | 1420-1470 | mT |

| coercivity bHc ? | 10.8-12.5 | kOe |

| coercivity bHc ? | 860-995 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 48-53 | BH max MGOe |

| energy density [min. - max.] ? | 380-422 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more offers

Pros as well as cons of rare earth magnets.

Strengths

- They have constant strength, and over around 10 years their attraction force decreases symbolically – ~1% (in testing),

- They do not lose their magnetic properties even under close interference source,

- A magnet with a shiny silver surface has an effective appearance,

- Magnetic induction on the working layer of the magnet remains strong,

- Through (appropriate) combination of ingredients, they can achieve high thermal resistance, enabling operation at temperatures reaching 230°C and above...

- Possibility of individual machining as well as modifying to specific requirements,

- Universal use in innovative solutions – they serve a role in hard drives, motor assemblies, medical equipment, and technologically advanced constructions.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Cons

- At very strong impacts they can crack, therefore we advise placing them in steel cases. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- Neodymium magnets decrease their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- They rust in a humid environment - during use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- Limited ability of making threads in the magnet and complicated shapes - recommended is a housing - mounting mechanism.

- Possible danger resulting from small fragments of magnets are risky, when accidentally swallowed, which is particularly important in the aspect of protecting the youngest. Additionally, tiny parts of these products are able to complicate diagnosis medical in case of swallowing.

- With large orders the cost of neodymium magnets is a challenge,

Pull force analysis

Breakaway strength of the magnet in ideal conditions – what contributes to it?

- with the contact of a yoke made of low-carbon steel, guaranteeing full magnetic saturation

- possessing a thickness of at least 10 mm to avoid saturation

- with a surface perfectly flat

- under conditions of no distance (surface-to-surface)

- for force acting at a right angle (pull-off, not shear)

- at conditions approx. 20°C

Key elements affecting lifting force

- Clearance – the presence of foreign body (rust, dirt, air) acts as an insulator, which reduces capacity rapidly (even by 50% at 0.5 mm).

- Force direction – remember that the magnet has greatest strength perpendicularly. Under shear forces, the capacity drops drastically, often to levels of 20-30% of the maximum value.

- Element thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Steel grade – the best choice is pure iron steel. Cast iron may have worse magnetic properties.

- Surface finish – ideal contact is possible only on polished steel. Rough texture create air cushions, weakening the magnet.

- Temperature – heating the magnet causes a temporary drop of force. Check the thermal limit for a given model.

Lifting capacity was determined by applying a steel plate with a smooth surface of suitable thickness (min. 20 mm), under perpendicular detachment force, whereas under parallel forces the load capacity is reduced by as much as 5 times. Additionally, even a minimal clearance between the magnet’s surface and the plate lowers the load capacity.

Warnings

Serious injuries

Watch your fingers. Two large magnets will snap together immediately with a force of massive weight, destroying everything in their path. Exercise extreme caution!

Keep away from children

Adult use only. Tiny parts can be swallowed, leading to intestinal necrosis. Store away from kids and pets.

Compass and GPS

Be aware: rare earth magnets produce a field that interferes with precision electronics. Keep a safe distance from your phone, tablet, and GPS.

Nickel allergy

It is widely known that the nickel plating (the usual finish) is a strong allergen. If your skin reacts to metals, avoid direct skin contact and select encased magnets.

ICD Warning

Individuals with a ICD must keep an safe separation from magnets. The magnetism can disrupt the operation of the implant.

Magnet fragility

Despite metallic appearance, neodymium is delicate and cannot withstand shocks. Avoid impacts, as the magnet may crumble into sharp, dangerous pieces.

Heat sensitivity

Standard neodymium magnets (grade N) lose power when the temperature surpasses 80°C. This process is irreversible.

Threat to electronics

Powerful magnetic fields can corrupt files on credit cards, HDDs, and other magnetic media. Keep a distance of min. 10 cm.

Handling guide

Exercise caution. Rare earth magnets attract from a long distance and connect with huge force, often faster than you can react.

Combustion hazard

Fire warning: Neodymium dust is explosive. Avoid machining magnets in home conditions as this risks ignition.