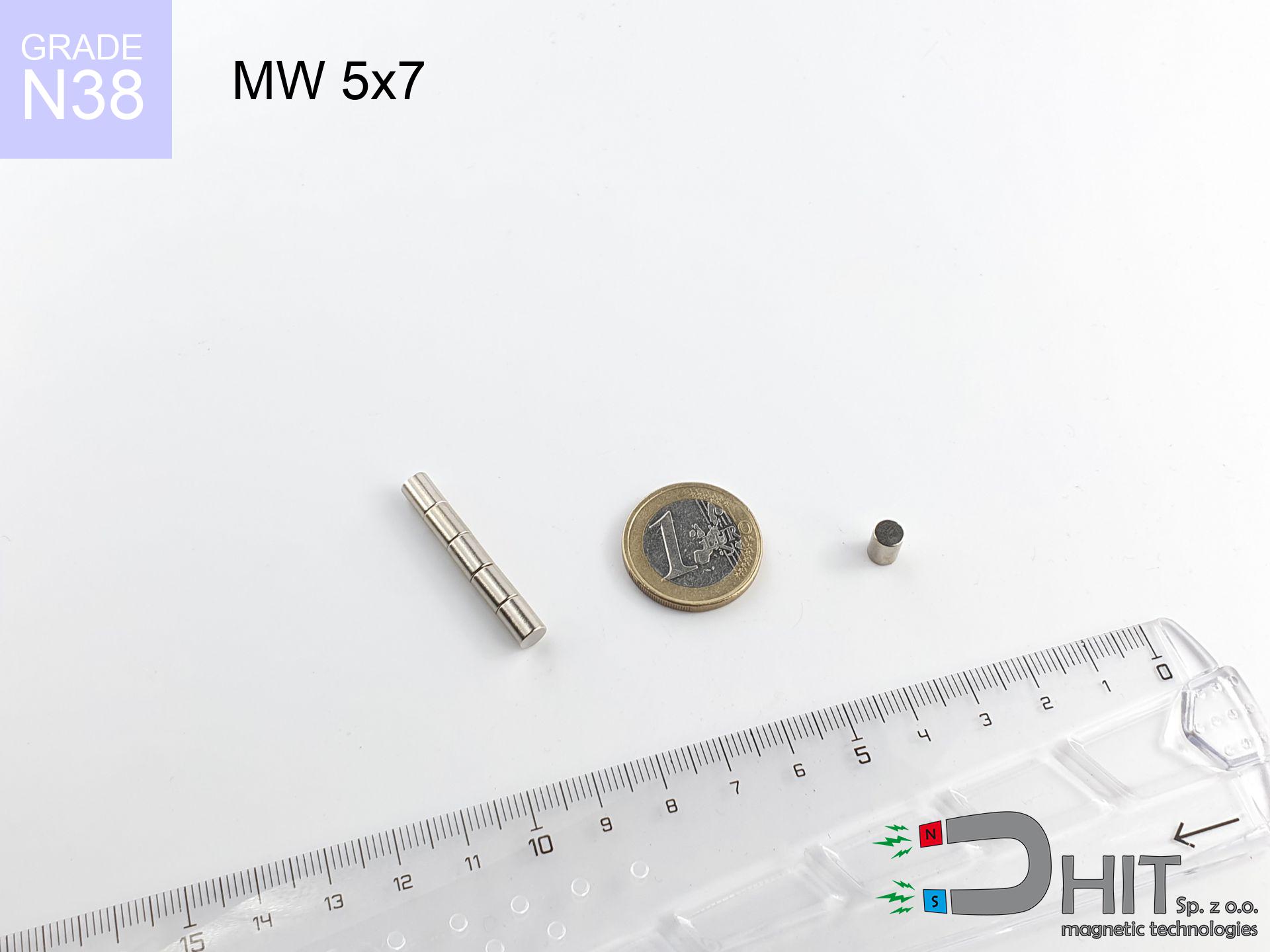

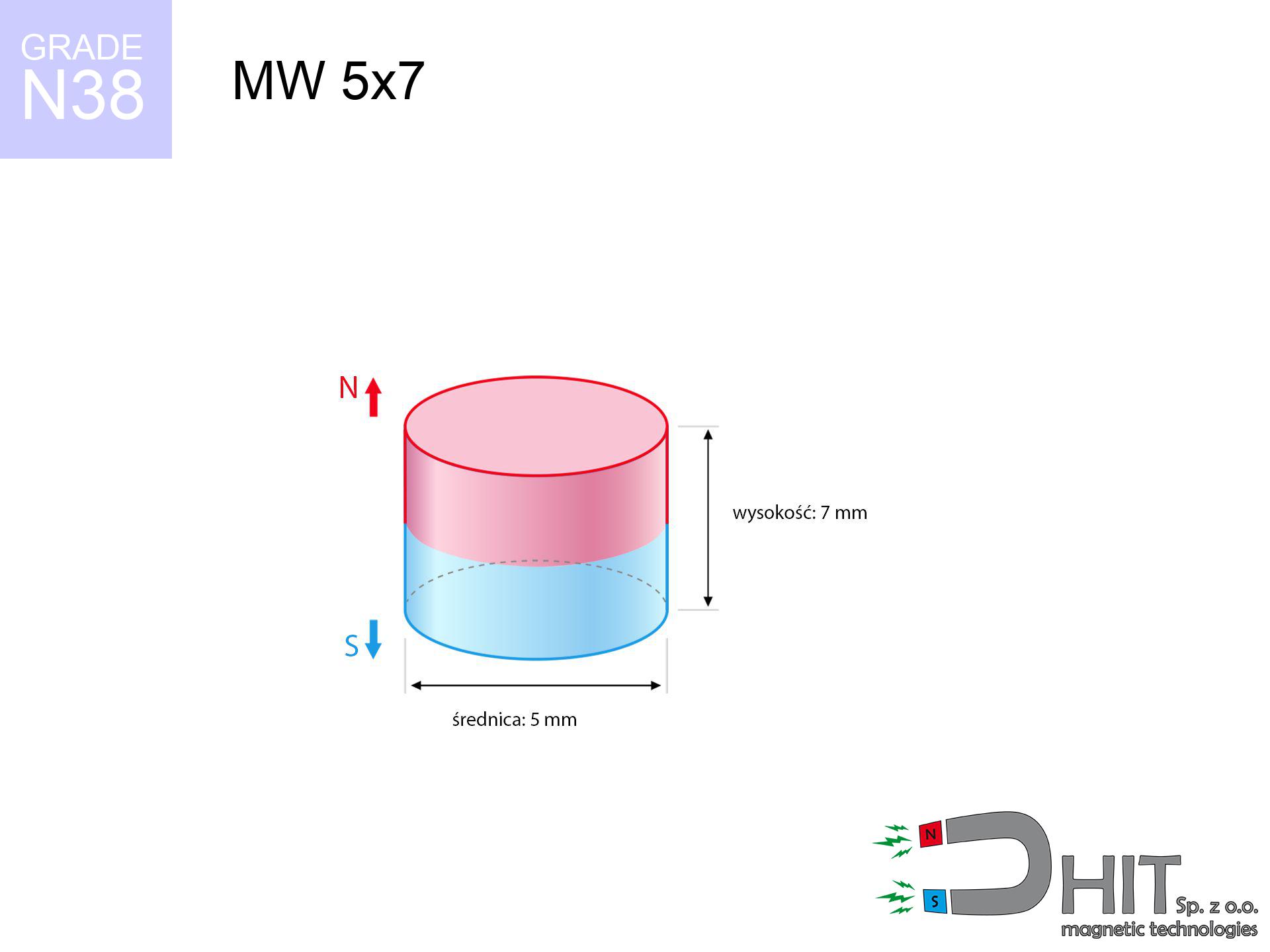

MW 5x7 / N38 - neodymium magnet

cylindrical magnet

catalog number 010090

GTIN: 5906301810896

diameter Ø

5 mm [±0,1 mm]

height

7 mm [±0,1 mm]

magnetizing direction

↑ axial

capacity ~

1.94 kg / 19.02 N

magnetic induction ~

582.40 mT / 5,824 Gs

max. temperature

≤ 80 °C

0.73 PLN gross price (including VAT) / pcs +

0.59 PLN net price + 23% VAT / pcs

bulk discounts:

need more quantity?Want to talk about magnets?

Give us a call tel: +48 888 99 98 98 or contact us through contact form on our website. You can check the lifting capacity as well as the appearance of neodymium magnets in our power calculator magnetic calculator

Orders placed by 2:00 PM will be shipped on the same business day.

Specification: cylindrical magnet 5x7 / N38 ↑ axial

Magnetic properties of the material N38

Physical properties of sintered neodymium magnets Nd2Fe14B

Moreover, although neodymium is part of the strongest magnets, they are prone to corrosion in humid environments. Therefore, they are coated with a coating of gold-nickel to protect them from corrosion. It's worth noting that NdFeB neodymium magnets are about 13% lighter than SmCo magnets and, despite their power, easily break, which requires care during their handling. For this reason, any mechanical processing should be done before they are magnetized.

In terms of safety, there are many recommendations regarding the use of these magnets. It is advisable to avoid their use in acidic, basic, organic environments or where solvents are present, and also in water or oil. Furthermore, they can damage data on magnetic cards and hard drives, although data deletion using a neodymium magnet is not always certain.

In terms of properties in different environments, neodymium magnets are susceptible to corrosion, especially in humid conditions. Therefore, they are often covered with thin coatings, such as nickel, to protect them from external factors and extend their lifespan. Temperatures exceeding 130°C can cause a loss of their magnetic properties, although there are specific types of neodymium magnets that can withstand temperatures up to 230°C.

As for dangers, it is important to avoid using neodymium magnets in acidic conditions, basic conditions, organic or solvent environments, unless they are adequately insulated. Additionally, their use is not recommended in wet conditions, oil, or in an atmosphere containing hydrogen, as they may forfeit their magnetic properties.

Product suggestions

Advantages as well as disadvantages of neodymium magnets NdFeB.

Apart from immense strength, neodymium magnets have the following advantages:

- They do not lose their power (of the magnet). After approximately 10 years, their strength decreases by only ~1% (theoretically),

- They protect against demagnetization caused by external magnetic sources extremely well,

- In other words, thanks to the shiny coating of nickel, gold, or silver, the element acquires an aesthetic appearance,

- They exhibit very high magnetic induction on the surface of the magnet,

- Magnetic neodymium magnets are characterized by hugely high magnetic induction on the surface of the magnet and can operate (depending on the shape) even at temperatures of 230°C or higher...

- Thanks to the flexibility in shaping and the ability to adapt to specific requirements – neodymium magnets can be produced in various forms and dimensions, which expands the range of their possible uses.

- Significant importance in advanced technologically fields – find application in HDD drives, electric drive mechanisms, medical devices and very modern machines.

Disadvantages of neodymium magnets:

- They can break when subjected to a powerful impact. If the magnets are exposed to impacts, we recommend using magnets in a steel housing. The steel housing in the form of a holder protects the magnet from impacts, and at the same time increases its overall strength,

- Magnets lose their strength due to exposure to high temperatures. In most cases, when the temperature exceeds 80°C, these magnets experience permanent reduction in strength (although it is worth noting that this is dependent on the form and size of the magnet). To avoid this problem, we offer special magnets marked with the [AH] symbol, which exhibit high temperature resistance. They can operate even at temperatures as high as 230°C or more,

- Magnets exposed to a humid environment can corrode. Therefore, when using them outdoors, we suggest using waterproof magnets made of rubber, plastic, or other moisture-resistant materials,

- The use of a cover or a magnetic holder is recommended due to the limited possibilities of manufacturing threads or complex shapes in the magnet

- Health risk to health from tiny fragments of magnets can be dangerous, if swallowed, which is particularly important in the context of children's health. Additionally, small elements of these magnets have the potential to hinder the diagnostic process when they are in the body.

Safety Precautions

Comparing neodymium magnets to ferrite magnets (found in speakers), they are 10 times more powerful, and their strength can surprise you.

Familiarize yourself with our information to correctly handle these magnets and avoid significant injuries to your body and prevent disruption to the magnets.

Neodymium magnets can become demagnetized at high temperatures.

In certain circumstances, Neodymium magnets can lose their magnetism when subjected to high temperatures.

Keep neodymium magnets away from TV, wallet, and computer HDD.

Neodymium magnets produce strong magnetic fields that can damage magnetic media such as floppy disks, video tapes, HDDs, credit cards, magnetic ID cards, cassette tapes, etc. devices. They can also destroy videos, televisions, CRT computer monitors. Do not forget to keep neodymium magnets at a safe distance from these electronic devices.

If you have a nickel allergy, avoid contact with neodymium magnets.

Studies show a small percentage of people have allergies to certain metals, including nickel. An allergic reaction often manifests as skin redness and rash. If you have a nickel allergy, you can try wearing gloves or simply avoid direct contact with nickel-plated neodymium magnets.

Under no circumstances should neodymium magnets be brought close to GPS and smartphones.

Neodymium magnets are a source of intense magnetic fields that cause interference with magnetometers and compasses used in navigation, as well as internal compasses of smartphones and GPS devices.

It is crucial not to allow the magnets to pinch together uncontrollably or place your fingers in their path as they attract to each other.

Neodymium magnets will bounce and also contact together within a radius of several to almost 10 cm from each other.

Dust and powder from neodymium magnets are highly flammable.

Avoid drilling or mechanical processing of neodymium magnets. Once crushed into fine powder or dust, this material becomes highly flammable.

Magnets made of neodymium are known for their fragility, which can cause them to crumble.

Neodymium magnets are fragile and will crack if allowed to collide with each other, even from a distance of a few centimeters. They are coated with a shiny nickel plating similar to steel, but they are not as hard. In the case of a collision between two magnets, there can be a scattering of small sharp metal fragments in different directions. Protecting your eyes is essential.

Neodymium magnets are not recommended for people with pacemakers.

Neodymium magnets generate very strong magnetic fields that can interfere with the operation of a pacemaker. This is because many of these devices are equipped with a function that deactivates the device in a magnetic field.

Do not give neodymium magnets to youngest children.

Neodymium magnets are not toys. Do not allow children to play with them. They can be a significant choking hazard. If multiple magnets are swallowed, they can attract to each other through the intestinal walls, causing significant injuries, and even death.

So you are aware of why neodymium magnets are so dangerous, read the article titled How dangerous are very strong neodymium magnets?.

![magnetic separator 25x175 [2xM8] / N52 magnetic separator 25x175 [2xM8] / N52](https://cdn3.dhit.pl/graphics/products/sm-25x175-2xm8-gif.jpg)

![magnetic separator 32x275 [2xM8] / N42 magnetic separator 32x275 [2xM8] / N42](https://cdn3.dhit.pl/graphics/products/sm-32x275-2xm8-hac.jpg)