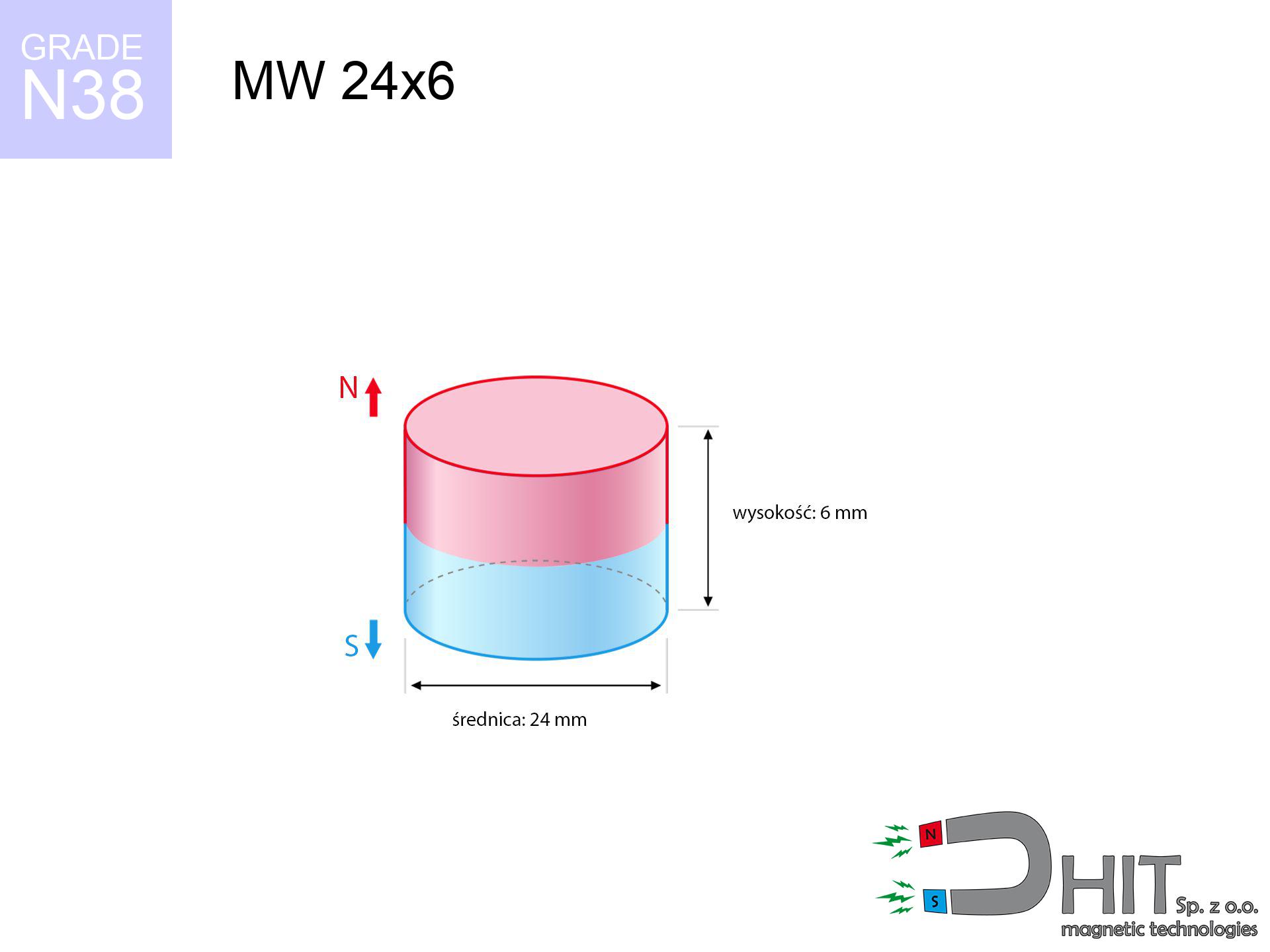

MW 24x6 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010048

GTIN/EAN: 5906301810476

Diameter Ø

24 mm [±0,1 mm]

Height

6 mm [±0,1 mm]

Weight

20.36 g

Magnetization Direction

↑ axial

Load capacity

9.98 kg / 97.88 N

Magnetic Induction

277.18 mT / 2772 Gs

Coating

[Zn] Zinc

5.10 ZŁ with VAT / pcs + price for transport

4.15 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

or drop us a message using

inquiry form

our website.

Specifications along with structure of a magnet can be checked using our

online calculation tool.

Order by 14:00 and we’ll ship today!

Technical details - MW 24x6 / N38 - cylindrical magnet

Specification / characteristics - MW 24x6 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010048 |

| GTIN/EAN | 5906301810476 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 24 mm [±0,1 mm] |

| Height | 6 mm [±0,1 mm] |

| Weight | 20.36 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 9.98 kg / 97.88 N |

| Magnetic Induction ~ ? | 277.18 mT / 2772 Gs |

| Coating | [Zn] Zinc |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the assembly - technical parameters

Presented information represent the outcome of a physical analysis. Results are based on models for the class Nd2Fe14B. Actual parameters may differ. Treat these calculations as a preliminary roadmap for designers.

Table 1: Static pull force (force vs gap) - characteristics

MW 24x6 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2771 Gs

277.1 mT

|

9.98 kg / 22.00 LBS

9980.0 g / 97.9 N

|

medium risk |

| 1 mm |

2609 Gs

260.9 mT

|

8.85 kg / 19.50 LBS

8846.4 g / 86.8 N

|

medium risk |

| 2 mm |

2420 Gs

242.0 mT

|

7.61 kg / 16.78 LBS

7609.6 g / 74.7 N

|

medium risk |

| 3 mm |

2216 Gs

221.6 mT

|

6.38 kg / 14.07 LBS

6383.0 g / 62.6 N

|

medium risk |

| 5 mm |

1805 Gs

180.5 mT

|

4.23 kg / 9.33 LBS

4233.2 g / 41.5 N

|

medium risk |

| 10 mm |

991 Gs

99.1 mT

|

1.28 kg / 2.81 LBS

1275.9 g / 12.5 N

|

low risk |

| 15 mm |

542 Gs

54.2 mT

|

0.38 kg / 0.84 LBS

381.4 g / 3.7 N

|

low risk |

| 20 mm |

313 Gs

31.3 mT

|

0.13 kg / 0.28 LBS

127.2 g / 1.2 N

|

low risk |

| 30 mm |

125 Gs

12.5 mT

|

0.02 kg / 0.04 LBS

20.4 g / 0.2 N

|

low risk |

| 50 mm |

34 Gs

3.4 mT

|

0.00 kg / 0.00 LBS

1.5 g / 0.0 N

|

low risk |

Table 2: Slippage capacity (wall)

MW 24x6 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

2.00 kg / 4.40 LBS

1996.0 g / 19.6 N

|

| 1 mm | Stal (~0.2) |

1.77 kg / 3.90 LBS

1770.0 g / 17.4 N

|

| 2 mm | Stal (~0.2) |

1.52 kg / 3.36 LBS

1522.0 g / 14.9 N

|

| 3 mm | Stal (~0.2) |

1.28 kg / 2.81 LBS

1276.0 g / 12.5 N

|

| 5 mm | Stal (~0.2) |

0.85 kg / 1.87 LBS

846.0 g / 8.3 N

|

| 10 mm | Stal (~0.2) |

0.26 kg / 0.56 LBS

256.0 g / 2.5 N

|

| 15 mm | Stal (~0.2) |

0.08 kg / 0.17 LBS

76.0 g / 0.7 N

|

| 20 mm | Stal (~0.2) |

0.03 kg / 0.06 LBS

26.0 g / 0.3 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 24x6 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.99 kg / 6.60 LBS

2994.0 g / 29.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

2.00 kg / 4.40 LBS

1996.0 g / 19.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.00 kg / 2.20 LBS

998.0 g / 9.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

4.99 kg / 11.00 LBS

4990.0 g / 49.0 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 24x6 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.00 kg / 2.20 LBS

998.0 g / 9.8 N

|

| 1 mm |

|

2.50 kg / 5.50 LBS

2495.0 g / 24.5 N

|

| 2 mm |

|

4.99 kg / 11.00 LBS

4990.0 g / 49.0 N

|

| 3 mm |

|

7.49 kg / 16.50 LBS

7485.0 g / 73.4 N

|

| 5 mm |

|

9.98 kg / 22.00 LBS

9980.0 g / 97.9 N

|

| 10 mm |

|

9.98 kg / 22.00 LBS

9980.0 g / 97.9 N

|

| 11 mm |

|

9.98 kg / 22.00 LBS

9980.0 g / 97.9 N

|

| 12 mm |

|

9.98 kg / 22.00 LBS

9980.0 g / 97.9 N

|

Table 5: Working in heat (stability) - power drop

MW 24x6 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

9.98 kg / 22.00 LBS

9980.0 g / 97.9 N

|

OK |

| 40 °C | -2.2% |

9.76 kg / 21.52 LBS

9760.4 g / 95.7 N

|

OK |

| 60 °C | -4.4% |

9.54 kg / 21.03 LBS

9540.9 g / 93.6 N

|

|

| 80 °C | -6.6% |

9.32 kg / 20.55 LBS

9321.3 g / 91.4 N

|

|

| 100 °C | -28.8% |

7.11 kg / 15.67 LBS

7105.8 g / 69.7 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MW 24x6 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

21.42 kg / 47.22 LBS

4 381 Gs

|

3.21 kg / 7.08 LBS

3213 g / 31.5 N

|

N/A |

| 1 mm |

20.25 kg / 44.65 LBS

5 390 Gs

|

3.04 kg / 6.70 LBS

3038 g / 29.8 N

|

18.23 kg / 40.19 LBS

~0 Gs

|

| 2 mm |

18.99 kg / 41.86 LBS

5 218 Gs

|

2.85 kg / 6.28 LBS

2848 g / 27.9 N

|

17.09 kg / 37.67 LBS

~0 Gs

|

| 3 mm |

17.67 kg / 38.95 LBS

5 034 Gs

|

2.65 kg / 5.84 LBS

2650 g / 26.0 N

|

15.90 kg / 35.06 LBS

~0 Gs

|

| 5 mm |

15.00 kg / 33.07 LBS

4 638 Gs

|

2.25 kg / 4.96 LBS

2250 g / 22.1 N

|

13.50 kg / 29.76 LBS

~0 Gs

|

| 10 mm |

9.09 kg / 20.03 LBS

3 610 Gs

|

1.36 kg / 3.00 LBS

1363 g / 13.4 N

|

8.18 kg / 18.03 LBS

~0 Gs

|

| 20 mm |

2.74 kg / 6.04 LBS

1 982 Gs

|

0.41 kg / 0.91 LBS

411 g / 4.0 N

|

2.46 kg / 5.43 LBS

~0 Gs

|

| 50 mm |

0.10 kg / 0.23 LBS

385 Gs

|

0.02 kg / 0.03 LBS

15 g / 0.2 N

|

0.09 kg / 0.21 LBS

~0 Gs

|

| 60 mm |

0.04 kg / 0.10 LBS

251 Gs

|

0.01 kg / 0.01 LBS

7 g / 0.1 N

|

0.04 kg / 0.09 LBS

~0 Gs

|

| 70 mm |

0.02 kg / 0.04 LBS

171 Gs

|

0.00 kg / 0.01 LBS

3 g / 0.0 N

|

0.02 kg / 0.04 LBS

~0 Gs

|

| 80 mm |

0.01 kg / 0.02 LBS

121 Gs

|

0.00 kg / 0.00 LBS

2 g / 0.0 N

|

0.01 kg / 0.02 LBS

~0 Gs

|

| 90 mm |

0.01 kg / 0.01 LBS

89 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.01 LBS

67 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (implants) - warnings

MW 24x6 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 10.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 8.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 6.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 5.0 cm |

| Car key | 50 Gs (5.0 mT) | 4.5 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MW 24x6 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

24.05 km/h

(6.68 m/s)

|

0.45 J | |

| 30 mm |

38.72 km/h

(10.76 m/s)

|

1.18 J | |

| 50 mm |

49.93 km/h

(13.87 m/s)

|

1.96 J | |

| 100 mm |

70.61 km/h

(19.61 m/s)

|

3.92 J |

Table 9: Anti-corrosion coating durability

MW 24x6 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [Zn] Zinc |

| Layer structure | Zn (Zinc) |

| Layer thickness | 8-15 µm |

| Salt spray test (SST) ? | 48 h |

| Recommended environment | Indoors / Garage |

Table 10: Electrical data (Pc)

MW 24x6 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 13 932 Mx | 139.3 µWb |

| Pc Coefficient | 0.35 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 24x6 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 9.98 kg | Standard |

| Water (riverbed) |

11.43 kg

(+1.45 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Warning: On a vertical surface, the magnet retains only ~20% of its max power.

2. Steel saturation

*Thin metal sheet (e.g. 0.5mm PC case) significantly limits the holding force.

3. Temperature resistance

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.35

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other products

Pros as well as cons of neodymium magnets.

Advantages

- They virtually do not lose strength, because even after 10 years the performance loss is only ~1% (based on calculations),

- They are extremely resistant to demagnetization induced by external magnetic fields,

- The use of an elegant layer of noble metals (nickel, gold, silver) causes the element to look better,

- The surface of neodymium magnets generates a unique magnetic field – this is a key feature,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- Thanks to flexibility in constructing and the capacity to customize to individual projects,

- Fundamental importance in future technologies – they serve a role in computer drives, drive modules, diagnostic systems, and other advanced devices.

- Thanks to efficiency per cm³, small magnets offer high operating force, in miniature format,

Disadvantages

- They are fragile upon too strong impacts. To avoid cracks, it is worth protecting magnets in a protective case. Such protection not only shields the magnet but also increases its resistance to damage

- When exposed to high temperature, neodymium magnets suffer a drop in force. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can rust. Therefore when using outdoors, we recommend using waterproof magnets made of rubber, plastic or other material protecting against moisture

- We recommend cover - magnetic mount, due to difficulties in producing nuts inside the magnet and complicated forms.

- Health risk related to microscopic parts of magnets are risky, when accidentally swallowed, which is particularly important in the aspect of protecting the youngest. Furthermore, small elements of these products can disrupt the diagnostic process medical when they are in the body.

- Due to expensive raw materials, their price exceeds standard values,

Pull force analysis

Optimal lifting capacity of a neodymium magnet – what affects it?

- using a sheet made of low-carbon steel, acting as a circuit closing element

- with a cross-section no less than 10 mm

- with an ideally smooth touching surface

- without any clearance between the magnet and steel

- for force applied at a right angle (in the magnet axis)

- at conditions approx. 20°C

Lifting capacity in practice – influencing factors

- Distance – the presence of any layer (rust, tape, air) acts as an insulator, which lowers capacity steeply (even by 50% at 0.5 mm).

- Pull-off angle – remember that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops drastically, often to levels of 20-30% of the maximum value.

- Wall thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field passes through the material instead of generating force.

- Chemical composition of the base – mild steel attracts best. Alloy steels lower magnetic permeability and holding force.

- Plate texture – ground elements ensure maximum contact, which increases force. Uneven metal reduce efficiency.

- Temperature – heating the magnet causes a temporary drop of induction. Check the thermal limit for a given model.

Holding force was measured on the plate surface of 20 mm thickness, when a perpendicular force was applied, however under parallel forces the holding force is lower. Moreover, even a minimal clearance between the magnet and the plate lowers the load capacity.

Warnings

Immense force

Use magnets consciously. Their powerful strength can shock even experienced users. Plan your moves and do not underestimate their power.

This is not a toy

Strictly keep magnets out of reach of children. Choking hazard is significant, and the consequences of magnets connecting inside the body are fatal.

Machining danger

Fire warning: Rare earth powder is highly flammable. Do not process magnets without safety gear as this may cause fire.

Shattering risk

Despite the nickel coating, the material is delicate and cannot withstand shocks. Do not hit, as the magnet may shatter into hazardous fragments.

Crushing force

Risk of injury: The attraction force is so great that it can cause blood blisters, crushing, and even bone fractures. Use thick gloves.

Warning for allergy sufferers

Warning for allergy sufferers: The Ni-Cu-Ni coating contains nickel. If skin irritation appears, cease working with magnets and use protective gear.

Protect data

Very strong magnetic fields can destroy records on payment cards, HDDs, and storage devices. Keep a distance of min. 10 cm.

Operating temperature

Regular neodymium magnets (N-type) lose power when the temperature surpasses 80°C. This process is irreversible.

Danger to pacemakers

For implant holders: Strong magnetic fields affect medical devices. Maintain minimum 30 cm distance or request help to work with the magnets.

Precision electronics

GPS units and smartphones are highly sensitive to magnetism. Direct contact with a strong magnet can permanently damage the sensors in your phone.

![SM 32x200 [2xM8] / N42 - magnetic separator SM 32x200 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x200-2xm8-fub.jpg)