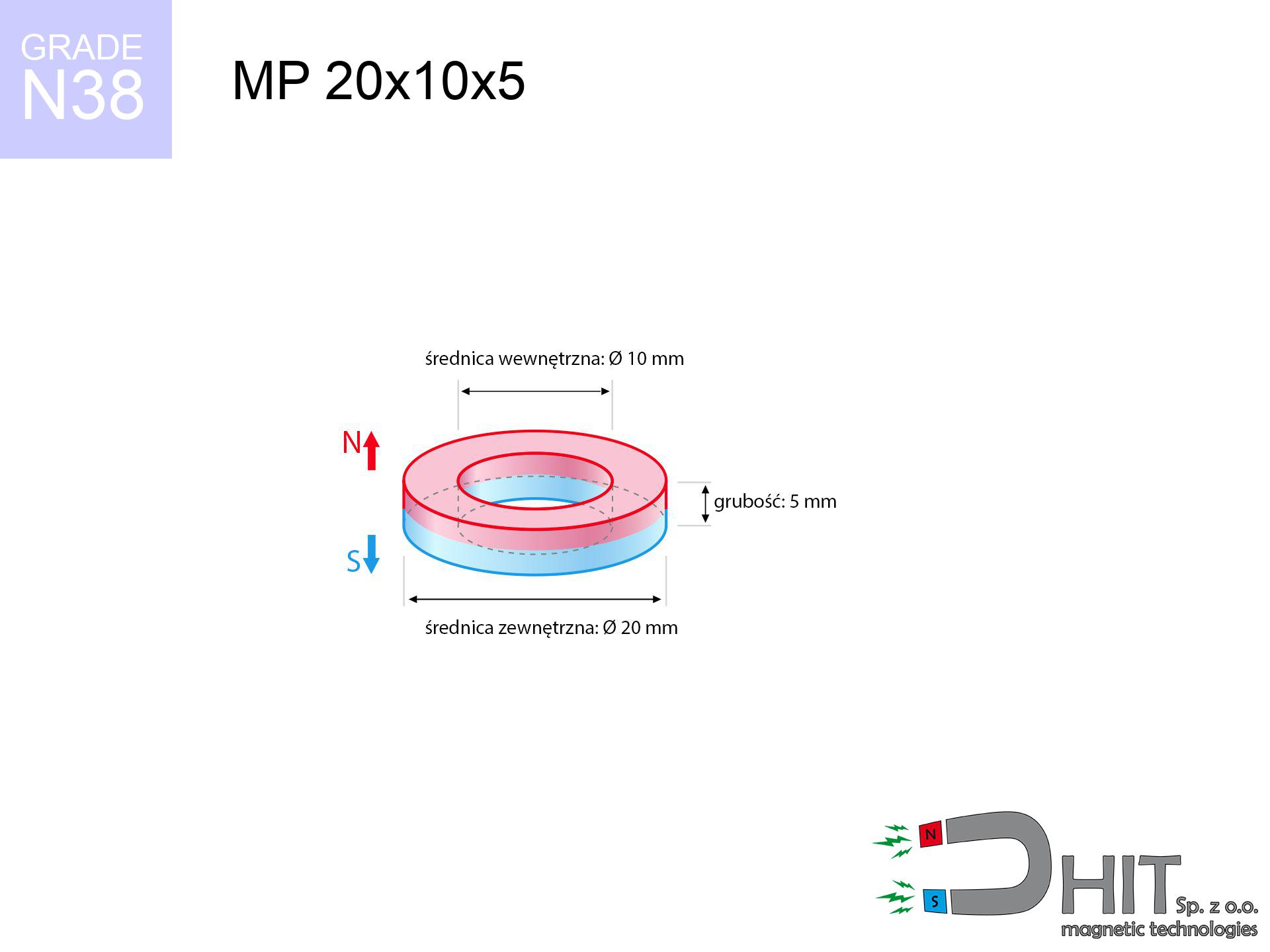

MP 20x10x5 / N38 - ring magnet

ring magnet

Catalog no 030184

GTIN/EAN: 5906301812012

Diameter

20 mm [±0,1 mm]

internal diameter Ø

10 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

8.84 g

Magnetization Direction

↑ axial

Load capacity

5.20 kg / 50.97 N

Magnetic Induction

277.16 mT / 2772 Gs

Coating

[NiCuNi] Nickel

4.50 ZŁ with VAT / pcs + price for transport

3.66 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

otherwise contact us using

request form

the contact section.

Specifications as well as shape of magnetic components can be tested with our

magnetic mass calculator.

Orders submitted before 14:00 will be dispatched today!

Technical data - MP 20x10x5 / N38 - ring magnet

Specification / characteristics - MP 20x10x5 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030184 |

| GTIN/EAN | 5906301812012 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 20 mm [±0,1 mm] |

| internal diameter Ø | 10 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 8.84 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 5.20 kg / 50.97 N |

| Magnetic Induction ~ ? | 277.16 mT / 2772 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the assembly - report

These information constitute the result of a physical analysis. Results are based on models for the class Nd2Fe14B. Actual parameters might slightly differ. Please consider these calculations as a reference point during assembly planning.

Table 1: Static pull force (pull vs gap) - characteristics

MP 20x10x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5917 Gs

591.7 mT

|

5.20 kg / 11.46 lbs

5200.0 g / 51.0 N

|

warning |

| 1 mm |

5321 Gs

532.1 mT

|

4.21 kg / 9.27 lbs

4205.9 g / 41.3 N

|

warning |

| 2 mm |

4736 Gs

473.6 mT

|

3.33 kg / 7.35 lbs

3332.2 g / 32.7 N

|

warning |

| 3 mm |

4184 Gs

418.4 mT

|

2.60 kg / 5.73 lbs

2600.0 g / 25.5 N

|

warning |

| 5 mm |

3216 Gs

321.6 mT

|

1.54 kg / 3.39 lbs

1536.2 g / 15.1 N

|

safe |

| 10 mm |

1650 Gs

165.0 mT

|

0.40 kg / 0.89 lbs

404.2 g / 4.0 N

|

safe |

| 15 mm |

907 Gs

90.7 mT

|

0.12 kg / 0.27 lbs

122.3 g / 1.2 N

|

safe |

| 20 mm |

544 Gs

54.4 mT

|

0.04 kg / 0.10 lbs

44.0 g / 0.4 N

|

safe |

| 30 mm |

240 Gs

24.0 mT

|

0.01 kg / 0.02 lbs

8.5 g / 0.1 N

|

safe |

| 50 mm |

75 Gs

7.5 mT

|

0.00 kg / 0.00 lbs

0.8 g / 0.0 N

|

safe |

Table 2: Vertical load (wall)

MP 20x10x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.04 kg / 2.29 lbs

1040.0 g / 10.2 N

|

| 1 mm | Stal (~0.2) |

0.84 kg / 1.86 lbs

842.0 g / 8.3 N

|

| 2 mm | Stal (~0.2) |

0.67 kg / 1.47 lbs

666.0 g / 6.5 N

|

| 3 mm | Stal (~0.2) |

0.52 kg / 1.15 lbs

520.0 g / 5.1 N

|

| 5 mm | Stal (~0.2) |

0.31 kg / 0.68 lbs

308.0 g / 3.0 N

|

| 10 mm | Stal (~0.2) |

0.08 kg / 0.18 lbs

80.0 g / 0.8 N

|

| 15 mm | Stal (~0.2) |

0.02 kg / 0.05 lbs

24.0 g / 0.2 N

|

| 20 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

8.0 g / 0.1 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MP 20x10x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.56 kg / 3.44 lbs

1560.0 g / 15.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.04 kg / 2.29 lbs

1040.0 g / 10.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.52 kg / 1.15 lbs

520.0 g / 5.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.60 kg / 5.73 lbs

2600.0 g / 25.5 N

|

Table 4: Material efficiency (saturation) - power losses

MP 20x10x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.52 kg / 1.15 lbs

520.0 g / 5.1 N

|

| 1 mm |

|

1.30 kg / 2.87 lbs

1300.0 g / 12.8 N

|

| 2 mm |

|

2.60 kg / 5.73 lbs

2600.0 g / 25.5 N

|

| 3 mm |

|

3.90 kg / 8.60 lbs

3900.0 g / 38.3 N

|

| 5 mm |

|

5.20 kg / 11.46 lbs

5200.0 g / 51.0 N

|

| 10 mm |

|

5.20 kg / 11.46 lbs

5200.0 g / 51.0 N

|

| 11 mm |

|

5.20 kg / 11.46 lbs

5200.0 g / 51.0 N

|

| 12 mm |

|

5.20 kg / 11.46 lbs

5200.0 g / 51.0 N

|

Table 5: Working in heat (material behavior) - thermal limit

MP 20x10x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

5.20 kg / 11.46 lbs

5200.0 g / 51.0 N

|

OK |

| 40 °C | -2.2% |

5.09 kg / 11.21 lbs

5085.6 g / 49.9 N

|

OK |

| 60 °C | -4.4% |

4.97 kg / 10.96 lbs

4971.2 g / 48.8 N

|

OK |

| 80 °C | -6.6% |

4.86 kg / 10.71 lbs

4856.8 g / 47.6 N

|

|

| 100 °C | -28.8% |

3.70 kg / 8.16 lbs

3702.4 g / 36.3 N

|

Table 6: Two magnets (attraction) - forces in the system

MP 20x10x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

54.03 kg / 119.11 lbs

6 121 Gs

|

8.10 kg / 17.87 lbs

8104 g / 79.5 N

|

N/A |

| 1 mm |

48.76 kg / 107.50 lbs

11 242 Gs

|

7.31 kg / 16.13 lbs

7314 g / 71.8 N

|

43.89 kg / 96.75 lbs

~0 Gs

|

| 2 mm |

43.70 kg / 96.34 lbs

10 642 Gs

|

6.55 kg / 14.45 lbs

6555 g / 64.3 N

|

39.33 kg / 86.71 lbs

~0 Gs

|

| 3 mm |

38.98 kg / 85.94 lbs

10 051 Gs

|

5.85 kg / 12.89 lbs

5847 g / 57.4 N

|

35.08 kg / 77.34 lbs

~0 Gs

|

| 5 mm |

30.63 kg / 67.54 lbs

8 910 Gs

|

4.60 kg / 10.13 lbs

4595 g / 45.1 N

|

27.57 kg / 60.78 lbs

~0 Gs

|

| 10 mm |

15.96 kg / 35.19 lbs

6 432 Gs

|

2.39 kg / 5.28 lbs

2394 g / 23.5 N

|

14.36 kg / 31.67 lbs

~0 Gs

|

| 20 mm |

4.20 kg / 9.26 lbs

3 299 Gs

|

0.63 kg / 1.39 lbs

630 g / 6.2 N

|

3.78 kg / 8.33 lbs

~0 Gs

|

| 50 mm |

0.19 kg / 0.42 lbs

702 Gs

|

0.03 kg / 0.06 lbs

29 g / 0.3 N

|

0.17 kg / 0.38 lbs

~0 Gs

|

| 60 mm |

0.09 kg / 0.20 lbs

480 Gs

|

0.01 kg / 0.03 lbs

13 g / 0.1 N

|

0.08 kg / 0.18 lbs

~0 Gs

|

| 70 mm |

0.05 kg / 0.10 lbs

342 Gs

|

0.01 kg / 0.01 lbs

7 g / 0.1 N

|

0.04 kg / 0.09 lbs

~0 Gs

|

| 80 mm |

0.02 kg / 0.05 lbs

253 Gs

|

0.00 kg / 0.01 lbs

4 g / 0.0 N

|

0.02 kg / 0.05 lbs

~0 Gs

|

| 90 mm |

0.01 kg / 0.03 lbs

193 Gs

|

0.00 kg / 0.00 lbs

2 g / 0.0 N

|

0.01 kg / 0.03 lbs

~0 Gs

|

| 100 mm |

0.01 kg / 0.02 lbs

150 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Safety (HSE) (implants) - warnings

MP 20x10x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 14.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 11.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 9.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 6.5 cm |

| Car key | 50 Gs (5.0 mT) | 6.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Impact energy (kinetic energy) - collision effects

MP 20x10x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

25.62 km/h

(7.12 m/s)

|

0.22 J | |

| 30 mm |

42.41 km/h

(11.78 m/s)

|

0.61 J | |

| 50 mm |

54.70 km/h

(15.19 m/s)

|

1.02 J | |

| 100 mm |

77.35 km/h

(21.49 m/s)

|

2.04 J |

Table 9: Coating parameters (durability)

MP 20x10x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MP 20x10x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 16 116 Mx | 161.2 µWb |

| Pc Coefficient | 1.13 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MP 20x10x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 5.20 kg | Standard |

| Water (riverbed) |

5.95 kg

(+0.75 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical surface, the magnet holds only approx. 20-30% of its nominal pull.

2. Steel saturation

*Thin steel (e.g. computer case) severely limits the holding force.

3. Heat tolerance

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.13

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more products

Strengths as well as weaknesses of neodymium magnets.

Benefits

- Their magnetic field is maintained, and after around 10 years it drops only by ~1% (theoretically),

- They maintain their magnetic properties even under external field action,

- Thanks to the glossy finish, the layer of nickel, gold-plated, or silver-plated gives an professional appearance,

- Neodymium magnets ensure maximum magnetic induction on a their surface, which increases force concentration,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to modularity in designing and the ability to adapt to complex applications,

- Fundamental importance in advanced technology sectors – they are used in data components, electric drive systems, precision medical tools, and other advanced devices.

- Thanks to concentrated force, small magnets offer high operating force, with minimal size,

Cons

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only protects the magnet but also improves its resistance to damage

- Neodymium magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material immune to moisture, in case of application outdoors

- Limited ability of creating nuts in the magnet and complex shapes - preferred is cover - magnet mounting.

- Potential hazard related to microscopic parts of magnets can be dangerous, if swallowed, which is particularly important in the context of child health protection. Furthermore, small elements of these magnets are able to be problematic in diagnostics medical when they are in the body.

- Due to expensive raw materials, their price exceeds standard values,

Pull force analysis

Magnetic strength at its maximum – what it depends on?

- using a sheet made of low-carbon steel, functioning as a magnetic yoke

- whose thickness equals approx. 10 mm

- with an ground contact surface

- under conditions of no distance (metal-to-metal)

- for force applied at a right angle (pull-off, not shear)

- at temperature room level

Determinants of lifting force in real conditions

- Air gap (between the magnet and the metal), as even a very small distance (e.g. 0.5 mm) results in a reduction in force by up to 50% (this also applies to paint, corrosion or debris).

- Force direction – declared lifting capacity refers to detachment vertically. When attempting to slide, the magnet exhibits much less (typically approx. 20-30% of maximum force).

- Metal thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field penetrates through instead of converting into lifting capacity.

- Material composition – not every steel reacts the same. Alloy additives weaken the attraction effect.

- Plate texture – smooth surfaces ensure maximum contact, which improves field saturation. Uneven metal weaken the grip.

- Thermal factor – hot environment weakens magnetic field. Too high temperature can permanently damage the magnet.

Holding force was checked on the plate surface of 20 mm thickness, when the force acted perpendicularly, in contrast under shearing force the lifting capacity is smaller. Additionally, even a slight gap between the magnet and the plate reduces the lifting capacity.

H&S for magnets

Power loss in heat

Monitor thermal conditions. Exposing the magnet to high heat will ruin its magnetic structure and strength.

Impact on smartphones

Be aware: rare earth magnets produce a field that confuses sensitive sensors. Keep a safe distance from your mobile, device, and navigation systems.

Keep away from computers

Avoid bringing magnets near a wallet, computer, or TV. The magnetism can permanently damage these devices and wipe information from cards.

Bone fractures

Protect your hands. Two powerful magnets will snap together instantly with a force of massive weight, crushing anything in their path. Be careful!

Sensitization to coating

Medical facts indicate that the nickel plating (standard magnet coating) is a common allergen. For allergy sufferers, prevent direct skin contact or choose versions in plastic housing.

Medical interference

People with a ICD have to keep an absolute distance from magnets. The magnetism can interfere with the operation of the life-saving device.

Protective goggles

Neodymium magnets are sintered ceramics, meaning they are very brittle. Collision of two magnets will cause them breaking into shards.

Danger to the youngest

Adult use only. Small elements can be swallowed, causing serious injuries. Store away from children and animals.

Powerful field

Handle magnets consciously. Their powerful strength can surprise even professionals. Stay alert and do not underestimate their power.

Dust explosion hazard

Fire warning: Rare earth powder is explosive. Do not process magnets in home conditions as this risks ignition.

![SM 25x200 [2xM8] / N52 - magnetic separator SM 25x200 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x200-2xm8-jas.jpg)

![HH 42x8.8 [M6] / N38 - through hole magnetic holder HH 42x8.8 [M6] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-42x8.8-m6-hin.jpg)