AM Haczyk M5 - magnetic accessories

magnetic accessories

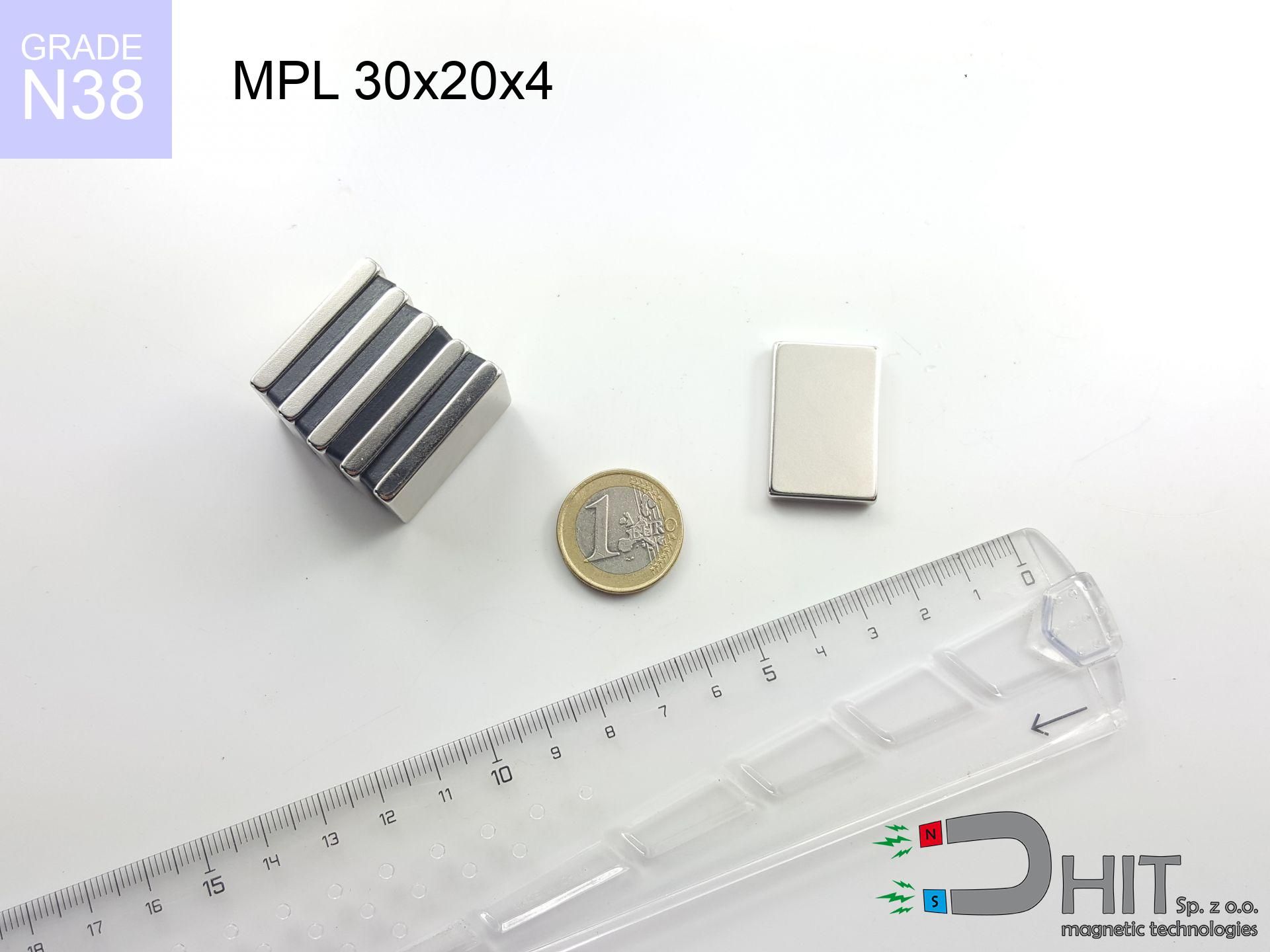

Catalog no 080506

Coating

[NiCuNi] Nickel

1.230 ZŁ with VAT / pcs + price for transport

1.000 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

if you prefer send us a note through

contact form

our website.

Parameters as well as shape of neodymium magnets can be analyzed on our

power calculator.

Order by 14:00 and we’ll ship today!

Detailed specification - AM Haczyk M5 - magnetic accessories

Specification / characteristics - AM Haczyk M5 - magnetic accessories

| properties | values |

|---|---|

| Cat. no. | 080506 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See more products

Pros and cons of rare earth magnets.

Strengths

- They do not lose strength, even after approximately 10 years – the reduction in strength is only ~1% (theoretically),

- They maintain their magnetic properties even under strong external field,

- A magnet with a smooth silver surface looks better,

- Neodymium magnets ensure maximum magnetic induction on a contact point, which increases force concentration,

- Through (appropriate) combination of ingredients, they can achieve high thermal strength, enabling functioning at temperatures approaching 230°C and above...

- Possibility of custom creating as well as optimizing to precise needs,

- Wide application in innovative solutions – they are commonly used in magnetic memories, electromotive mechanisms, advanced medical instruments, also other advanced devices.

- Thanks to efficiency per cm³, small magnets offer high operating force, with minimal size,

Cons

- Susceptibility to cracking is one of their disadvantages. Upon strong impact they can fracture. We recommend keeping them in a strong case, which not only secures them against impacts but also raises their durability

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- They oxidize in a humid environment - during use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- Limited ability of making threads in the magnet and complex forms - preferred is cover - mounting mechanism.

- Possible danger related to microscopic parts of magnets are risky, when accidentally swallowed, which gains importance in the context of child health protection. Furthermore, small elements of these products are able to complicate diagnosis medical when they are in the body.

- Due to expensive raw materials, their price is relatively high,

Holding force characteristics

Breakaway strength of the magnet in ideal conditions – what contributes to it?

- with the application of a sheet made of low-carbon steel, guaranteeing full magnetic saturation

- with a cross-section no less than 10 mm

- with a surface free of scratches

- with total lack of distance (without paint)

- under vertical application of breakaway force (90-degree angle)

- in temp. approx. 20°C

Lifting capacity in real conditions – factors

- Distance – the presence of any layer (rust, tape, air) acts as an insulator, which lowers capacity steeply (even by 50% at 0.5 mm).

- Force direction – declared lifting capacity refers to pulling vertically. When slipping, the magnet exhibits much less (typically approx. 20-30% of maximum force).

- Substrate thickness – for full efficiency, the steel must be sufficiently thick. Paper-thin metal restricts the attraction force (the magnet "punches through" it).

- Material composition – different alloys reacts the same. Alloy additives weaken the interaction with the magnet.

- Surface finish – ideal contact is obtained only on smooth steel. Any scratches and bumps create air cushions, weakening the magnet.

- Temperature – temperature increase causes a temporary drop of force. Check the thermal limit for a given model.

Lifting capacity was assessed with the use of a polished steel plate of optimal thickness (min. 20 mm), under perpendicular pulling force, in contrast under parallel forces the lifting capacity is smaller. Moreover, even a minimal clearance between the magnet and the plate lowers the holding force.

Safety rules for work with neodymium magnets

Swallowing risk

Strictly keep magnets out of reach of children. Risk of swallowing is significant, and the effects of magnets connecting inside the body are very dangerous.

Eye protection

Protect your eyes. Magnets can fracture upon uncontrolled impact, ejecting shards into the air. We recommend safety glasses.

Do not underestimate power

Use magnets with awareness. Their powerful strength can surprise even experienced users. Stay alert and do not underestimate their power.

ICD Warning

Warning for patients: Strong magnetic fields disrupt medical devices. Maintain minimum 30 cm distance or ask another person to handle the magnets.

Physical harm

Protect your hands. Two powerful magnets will join instantly with a force of several hundred kilograms, crushing everything in their path. Be careful!

Phone sensors

Navigation devices and mobile phones are highly susceptible to magnetism. Direct contact with a strong magnet can ruin the sensors in your phone.

Flammability

Powder generated during grinding of magnets is self-igniting. Avoid drilling into magnets unless you are an expert.

Warning for allergy sufferers

Nickel alert: The nickel-copper-nickel coating consists of nickel. If redness appears, cease working with magnets and use protective gear.

Safe distance

Powerful magnetic fields can destroy records on credit cards, hard drives, and other magnetic media. Maintain a gap of at least 10 cm.

Demagnetization risk

Monitor thermal conditions. Heating the magnet to high heat will permanently weaken its properties and strength.