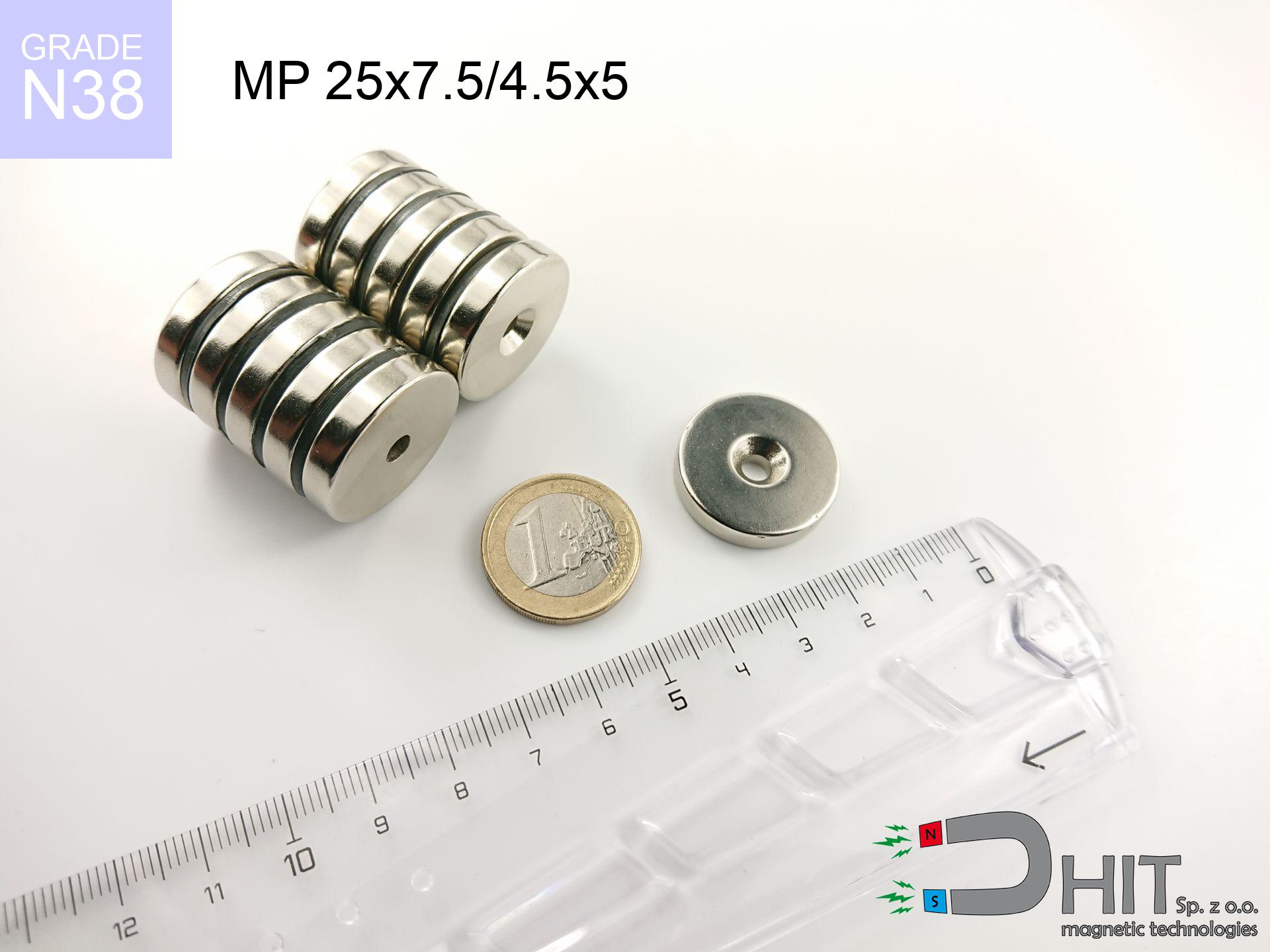

UMGW 25x17x8 [M5] GW / N38 - magnetic holder internal thread

magnetic holder internal thread

Catalog no 180317

GTIN: 5906301813736

Diameter Ø [±0,1 mm]

25 mm

Height [±0,1 mm]

17 mm

Height [±0,1 mm]

8 mm

Weight

25.4 g

Load capacity

17 kg / 166.71 N

11.91 ZŁ with VAT / pcs + price for transport

9.68 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?Looking for a better price?

Give us a call

+48 22 499 98 98

otherwise let us know using

request form

through our site.

Strength and form of a magnet can be estimated using our

our magnetic calculator.

Same-day shipping for orders placed before 14:00.

Magnetic properties of material N38

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

Shopping tips

Advantages as well as disadvantages of NdFeB magnets.

Besides their exceptional strength, neodymium magnets offer the following advantages:

- They virtually do not lose power, because even after 10 years the performance loss is only ~1% (based on calculations),

- They do not lose their magnetic properties even under strong external field,

- A magnet with a smooth silver surface looks better,

- The surface of neodymium magnets generates a strong magnetic field – this is one of their assets,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- In view of the possibility of flexible forming and adaptation to individualized projects, magnetic components can be modeled in a wide range of forms and dimensions, which makes them more universal,

- Wide application in innovative solutions – they find application in computer drives, motor assemblies, medical equipment, also other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in small dimensions, which allows their use in small systems

Problematic aspects of neodymium magnets: application proposals

- To avoid cracks upon strong impacts, we suggest using special steel housings. Such a solution secures the magnet and simultaneously improves its durability.

- We warn that neodymium magnets can lose their power at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material stable to moisture, in case of application outdoors

- Due to limitations in producing nuts and complicated forms in magnets, we propose using a housing - magnetic mechanism.

- Possible danger to health – tiny shards of magnets are risky, if swallowed, which is particularly important in the context of child safety. It is also worth noting that small elements of these devices can complicate diagnosis medical in case of swallowing.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Maximum holding power of the magnet – what it depends on?

Information about lifting capacity was determined for ideal contact conditions, assuming:

- on a block made of structural steel, perfectly concentrating the magnetic flux

- whose transverse dimension is min. 10 mm

- with a plane perfectly flat

- without the slightest air gap between the magnet and steel

- under axial force vector (90-degree angle)

- at temperature room level

Practical lifting capacity: influencing factors

Holding efficiency is influenced by specific conditions, such as (from most important):

- Distance – the presence of any layer (paint, dirt, air) interrupts the magnetic circuit, which lowers power steeply (even by 50% at 0.5 mm).

- Loading method – catalog parameter refers to detachment vertically. When attempting to slide, the magnet holds significantly lower power (typically approx. 20-30% of maximum force).

- Base massiveness – too thin sheet does not accept the full field, causing part of the flux to be lost into the air.

- Metal type – not every steel reacts the same. High carbon content weaken the attraction effect.

- Base smoothness – the smoother and more polished the surface, the better the adhesion and stronger the hold. Roughness creates an air distance.

- Temperature – temperature increase results in weakening of induction. It is worth remembering the thermal limit for a given model.

* Holding force was checked on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, however under parallel forces the lifting capacity is smaller. Moreover, even a slight gap {between} the magnet’s surface and the plate decreases the lifting capacity.

Safety rules for work with neodymium magnets

Sensitization to coating

Certain individuals suffer from a hypersensitivity to Ni, which is the standard coating for neodymium magnets. Extended handling may cause a rash. It is best to wear safety gloves.

Product not for children

Product intended for adults. Tiny parts pose a choking risk, causing severe trauma. Keep out of reach of children and animals.

Risk of cracking

Despite the nickel coating, the material is brittle and cannot withstand shocks. Do not hit, as the magnet may shatter into hazardous fragments.

Threat to navigation

GPS units and mobile phones are extremely sensitive to magnetic fields. Close proximity with a strong magnet can decalibrate the sensors in your phone.

Medical interference

Life threat: Strong magnets can turn off heart devices and defibrillators. Stay away if you have medical devices.

Respect the power

Before use, check safety instructions. Uncontrolled attraction can break the magnet or injure your hand. Think ahead.

Do not drill into magnets

Powder created during cutting of magnets is combustible. Avoid drilling into magnets unless you are an expert.

Bodily injuries

Big blocks can smash fingers in a fraction of a second. Under no circumstances place your hand betwixt two strong magnets.

Keep away from computers

Intense magnetic fields can erase data on credit cards, HDDs, and other magnetic media. Maintain a gap of at least 10 cm.

Maximum temperature

Regular neodymium magnets (grade N) undergo demagnetization when the temperature surpasses 80°C. The loss of strength is permanent.

Danger!

Learn more about risks in the article: Safety of working with magnets.

![Magnet for screw UMGW 25x17x8 [M5] GW / N38 Magnet for screw UMGW 25x17x8 [M5] GW / N38](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![UMGW 25x17x8 [M5] GW / N38 - magnetic holder internal thread](https://cdn3.dhit.pl/graphics/products/um-25x17x8-m5-gw-dob.jpg)

![UMGW 25x17x8 [M5] GW / N38 - magnetic holder internal thread - ujęcie 2](https://cdn3.dhit.pl/graphics/products/umgw-25x17x8-m5-gw-soh.jpg)