Neodymium magnets - Nd2Fe14B: specification and technology

Complete technical documentation of the strongest permanent magnets

1. Strip casting: the process begins with melting in an induction furnace in a protective atmosphere (argon). The molten metal is poured onto a rotating, water-cooled copper roller (SC alloy).

2. Decrepitation & jet milling: the material undergoes the HD (Hydrogen Decrepitation) process. Hydrogen causes the ingots to break down into smaller particles. Then, using jet mills in a nitrogen atmosphere, a powder with a particle diameter of approx. 3 µm is obtained.

3. Pressing and sintering: the powder is pressed in a strong magnetic field to obtain anisotropy (domain alignment). Then the "green" compacts go to vacuum furnaces (approx. 1050°C). Sintering is followed by a crucial annealing process at temperatures of 900°C and 600°C, which relieves stress and dissolves unstable phases.

4. Machining and magnetization: sinters are cut to size using precise wire saws, which minimizes the loss of valuable material (kerf). After coating, magnets are activated in pulse magnetizers with a field of approx. 5 Tesla.

Safety and operation principles

Critical conditions excluding the use of standard NdFeB magnets without specialized shielding:

- In acidic, alkaline, organic or dissolving environments (unless you hermetically isolate the magnet from the environment), or radioactive rays

- In water or oil (unless you isolate the magnet from the environment or are prepared for the magnet to lose its magnetic properties in a short time)

- In an electrically conductive fluid - electrolyte containing water

- In an atmosphere containing hydrogen

Material specification

Neodymium magnet (NdFeB) is a sintered rare-earth metal, currently the strongest permanent magnet available. It is characterized by an anisotropic tetragonal crystal structure of Nd2Fe14B. Compared to ferrites, it offers approx. 10 times higher energy density (BH)max, allowing for significant device miniaturization.

Due to the high iron content (approx. 64-68%) and neodymium, the neodymium-rich phase at the grain boundaries is highly reactive. This requires the use of barrier coatings (Ni-Cu-Ni, Epoxy, Parylene). An unprotected magnet oxidizes, forming hydroxides, leading to structural disintegration.

The material is brittle (ceramic-like). Machining is only possible with diamond tools before magnetization. Mechanical shocks should be avoided, as they can lead to micro-cracks (chipping).

Neodymium (Nd, atomic number 60) is a key component of the alloy. It is estimated that approx. 20-30% of neodymium in magnets is actually Praseodymium (Pr). Due to chemical similarity, a Pr-Nd alloy is used, which does not negatively affect the magnet's properties. In high-temperature magnets (UH, EH), part of the neodymium is replaced by Dysprosium (Dy) or Terbium (Tb).

- patent discovery year: 1984 (Sagawa / Croat)

- Nd atomic number: 60

- atomic mass: 144.24 u

- electronegativity (Pauling): 1.14

- valence: +3

- phase melting temp.: 1024°C

- boiling point: 3074°C

- stable isotopes: 5 (142, 143, 145, 146, 148)

- configuration: [Xe] 4f4 6s2

Permanent magnet definition

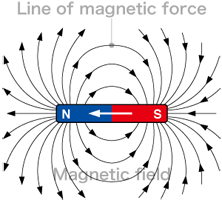

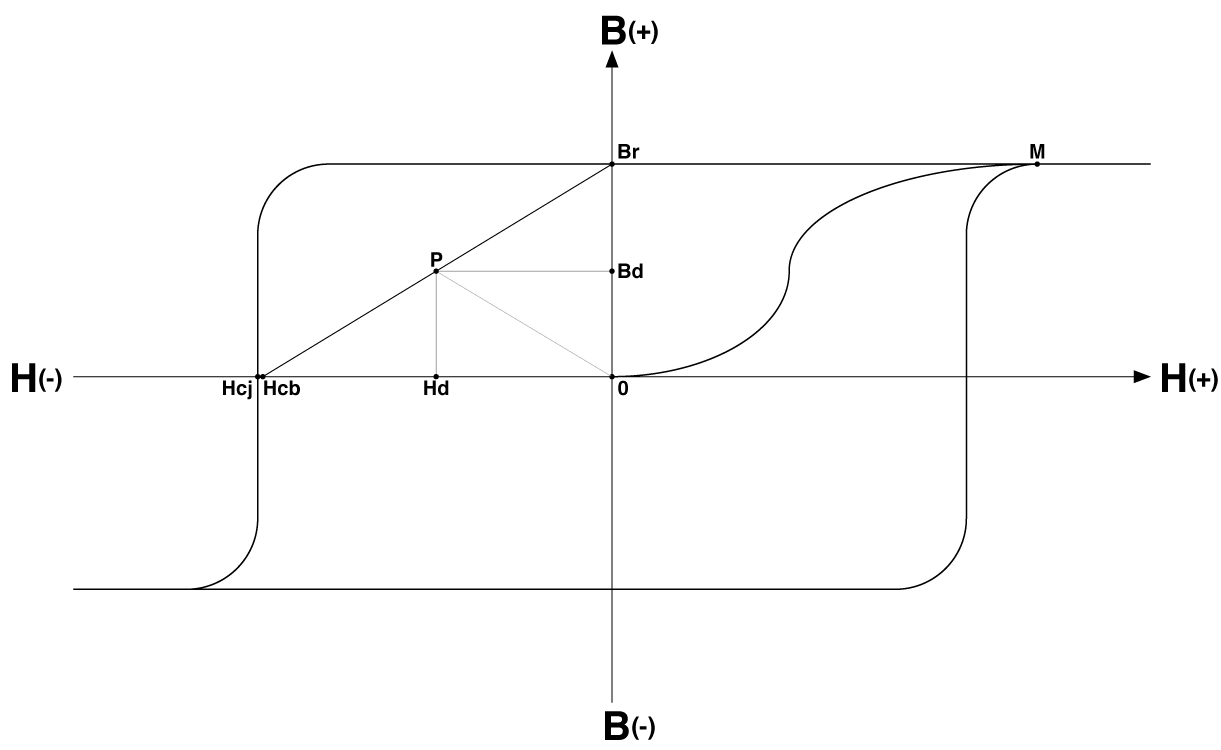

A permanent magnet is a material with a wide magnetic hysteresis loop, capable of maintaining magnetization after the external magnetizing field is removed. A key parameter is high coercivity (Hcj), preventing spontaneous demagnetization.

Demagnetization and Curie point

Loss of magnetic properties occurs under the influence of temperature (thermal agitation of domains) or an opposing magnetic field. The Curie point (Tc) is the temperature at which the material loses ferromagnetic properties and becomes paramagnetic (for NdFeB approx. 310-350°C).

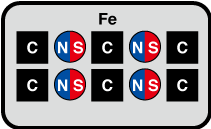

Nature of magnetism

A physical phenomenon resulting from the angular momentum (spin) of electrons and their orbital motion. In NdFeB magnets, the exchange coupling between iron atoms and rare earths plays a key role.

Evaluation methodology (BH curve)

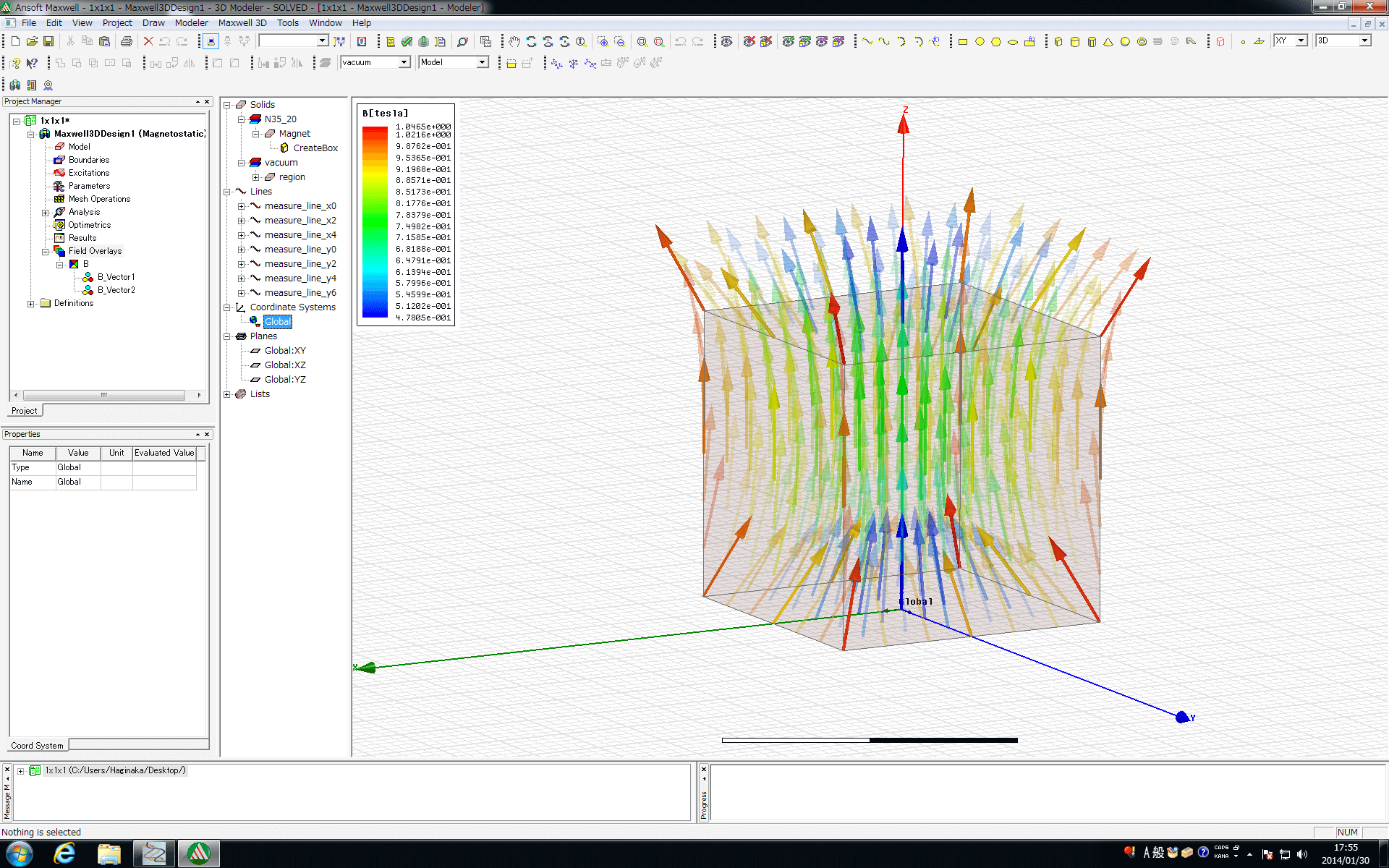

Professional magnet evaluation is performed using a hysteresigraph (BH analyzer). It determines four key points in the 2nd quadrant of the coordinate system: Br (remanence), HcB (induction coercivity), HcJ (polarization coercivity), and (BH)max.

Flux density (B)

Magnetic induction measured on the magnet surface (surface gauss). This value depends not only on the magnet grade (Br) but also on its geometry (permeance coefficient - Pc).

Coercivity (Hcb / Hcj)

Resistance to demagnetization. Hcb (normal coercivity) defines the point of zero induction, Hcj (intrinsic coercivity) defines the point of zero polarization - this is a key parameter for temperature resistance.

Maximum energy product (BH)max

The maximum amount of magnetic energy stored per unit volume of material. This value (in MGOe) roughly corresponds to the magnet grade number (e.g., N52 has approx. 52 MGOe).

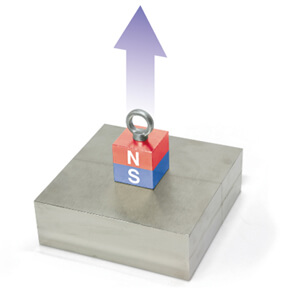

Pull force (attraction)

The perpendicular force required to detach a magnet from a low-carbon ferromagnet, with zero air gap. Laboratory values may differ from real ones due to surface roughness, steel composition, or force application angle.

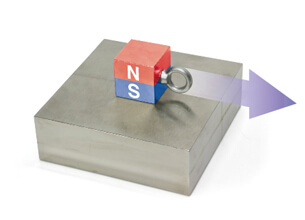

Shear force (sliding load)

Force acting parallel to the contact surface. It depends directly on the friction coefficient (µ) between the magnet coating and the substrate. For Ni-Cu-Ni coating, it is usually 15-20% of the vertical pull force. Using rubber increases this coefficient.

Measurement procedures

Measurement standards in the DHIT laboratory:

-

Pull-force test (perpendicular)

Perpendicular detachment at a speed of 10mm/min from a steel plate (St37) with a thickness of min. 10mm, ground.

-

Shear-force test (sliding)

Parallel sliding. The result is strongly dependent on the coating. For Ni, it is approx. 0.15-0.20 of the vertical force.

Measurement boundary conditions

Variables affecting the measurement result:

- Plate thickness: steel that is too thin becomes magnetically saturated, lowering the result.

- Positioning: central application of force.

- Working area: no plate edges in the immediate vicinity.

- Steel grade: preferred pure armco iron or low-carbon steel.

- Surface roughness (Ra).

- Air gap: even 0.1mm drastically reduces the force.

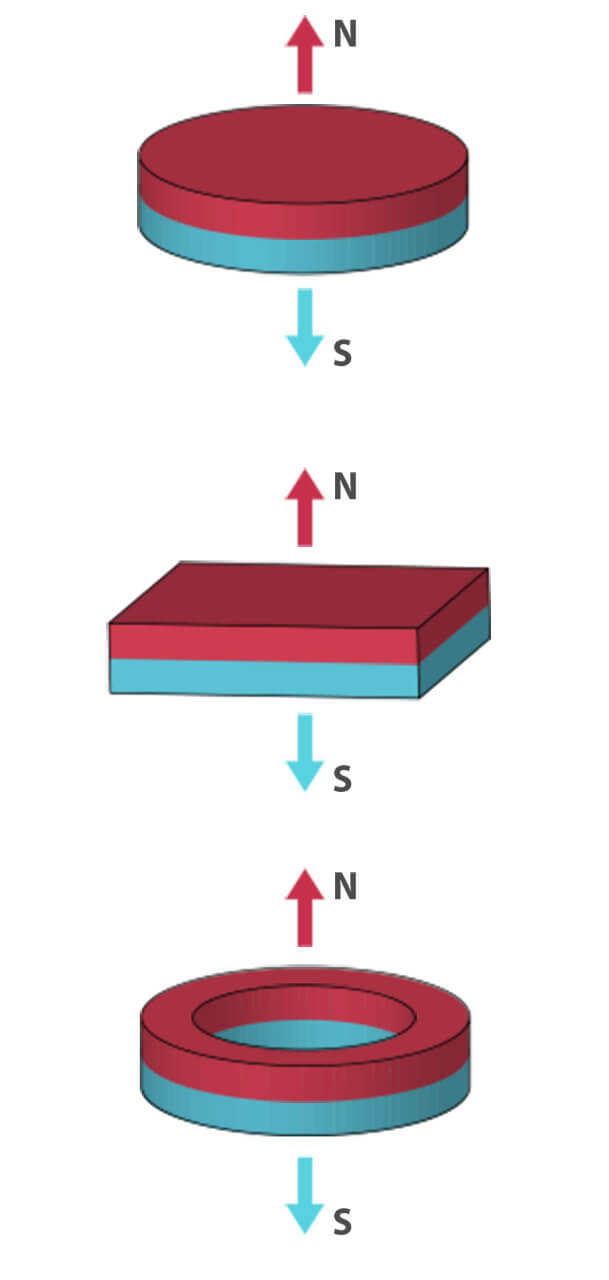

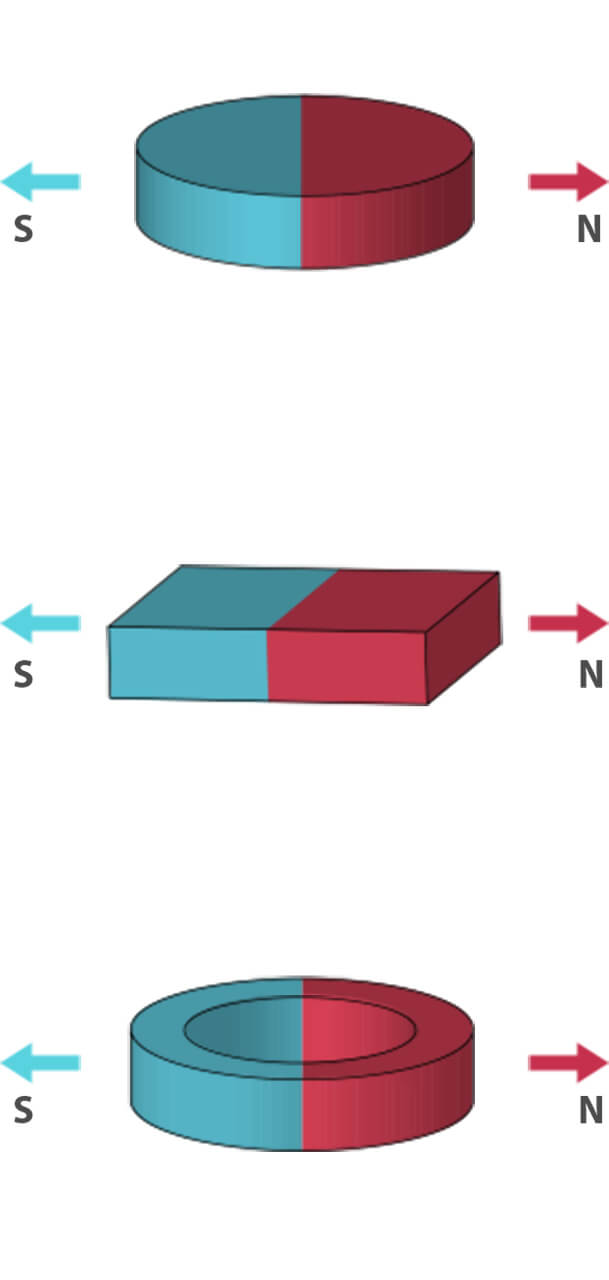

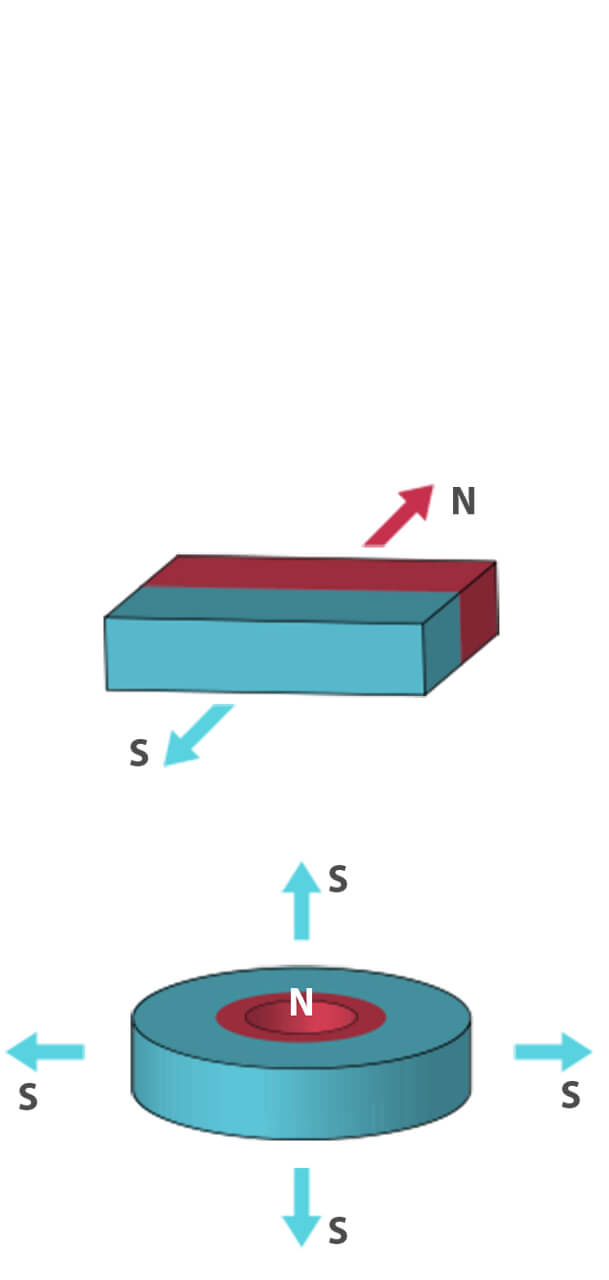

Anisotropy and magnetization directions

Axial

Magnetization vector parallel to the axis of symmetry (height). Most common configuration for cylinders and rings.

Diametrical

Magnetization vector perpendicular to the axis of symmetry (through the diameter).

Radial (multipole)

Specialized orientation (requires a separate mold for pressing). Poles distributed on the circumference.

Magnetic poles are always located on surfaces perpendicular to the orientation direction (easy axis).

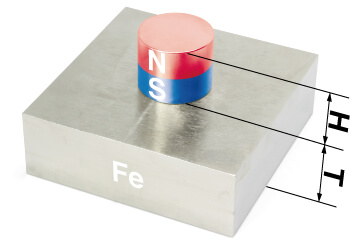

Cylindrical magnets

- axial: poles on flat bases.

- diametrical: poles on the cylinder curves.

- radial: multipole on the circumference (for rotors).

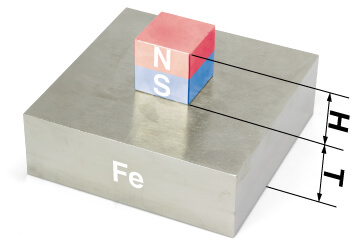

Plate magnets (blocks)

- through thickness (H): standard.

- through width (W).

- through length (L).

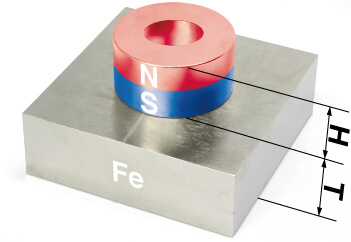

Ring magnets

- axial: standard.

- diametrical: 2 poles on the circumference.

- radial: special execution.

Alternative production methods (special technologies)

In addition to classic sintering, advanced methods are used to obtain specific properties:

1. Hydrogen method HDDR

The process (Hydrogenation, Disproportionation, Desorption, Recombination) takes place at 750-900°C. It allows obtaining powder with a very fine-grained structure and high coercivity. This material is often used for the production of bonded magnets.

2. Bonded Magnets

A mixture of magnetic powder (NdFeB) with a polymer binder (resin, plastic). Produced by injection molding or compression molding. Although they have weaker magnetic parameters than sintered ones, they are characterized by high shape precision without the need for machining, greater corrosion resistance, and flexibility.

3. Mechanical alloying

Milling powder in ball mills, leading to a nanocrystalline structure. After short annealing (approx. 700°C), a material with very high coercivity is obtained.

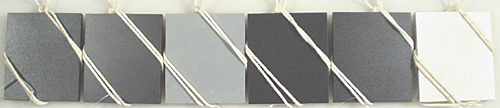

Surface engineering (coatings)

Due to the low corrosion resistance of the Nd-rich phase, coatings are mandatory. The thickness and type of coating affect dimensional tolerances and environmental resistance.

Ni-Cu-Ni (standard)

- Features: structure: nickel (base) + copper (elasticity/tightness) + nickel (finish).

- Color: appearance: silvery gloss.

- Price: advantages: best price-to-protection ratio.

- Thickness: thickness: 10-20 µm.

Ni-Cu-Ni-Au (gold)

Decorative and functional coating (conductivity).

- Layer: top layer: 24k industrial gold (thin layer).

- Color: application: medical (biocompatibility), electrical contacts.

- Au Thickness: Au thickness: ~0.05-0.1 µm.

- Total Thickness: base: requires full Ni-Cu-Ni undercoat.

Ni-Cu-Ni-Cr (chrome)

- Resistance: advantages: high resistance to abrasion (friction).

- Color: appearance: cold, bluish gloss.

- Thickness: thickness: ~15 µm.

Ni-Cu (copper)

Used less frequently as a final layer.

- Color: application: lower resistance, mainly aesthetic or as a base.

- Abrasion: disadvantage: copper quickly passivates (darkens).

- Corrosion: costs: lower than triple layer.

- Thickness: thickness: ~10 µm.

Epoxy (resin)

Black electrophoretic or spray coating

Ideal for marine and outdoor applications, as long as it is not exposed to impact.

- Color: resistance: excellent against moisture and salt spray.

- Corrosion: disadvantage: brittle, prone to mechanical scratches.

- Resistance: insulation: electrical.

- Thickness: thickness: 15-30 µm.

Rubber coated

Dedicated to automotive and mounting holders.

- Color: material: santoprene or synthetic rubber.

- Impact: function: increases friction (shear force), protects substrate paint.

- Friction: disadvantage: air gap (rubber thickness 0.5mm) significantly reduces perpendicular force.

- Thickness: thickness: 0.5 - 1.0 mm.

- Chemicals: water resistance: very high.

- Force: impact resistance: absorbs shocks.

Plastic overmolding

Full environmental protection.

- Color: material: ABS, PP, Nylon.

- Impact: tightness: complete (hermetic).

- Friction: durability: very high.

- Thickness: wall thickness: 1-2 mm.

- Chemicals: application: clothing industry, toys.

- Force: force reduction: significant (large gap).

Technical parameters of coatings

Detailed comparative data on corrosion resistance (SST and PCT tests):

| material | symbol | coating thickness (μm) | corrosion resistance (salt spray) (Hr) | porosity | demagnetization rate | color | PCT (Hr) |

|---|---|---|---|---|---|---|---|

| Zinc | Zn | 10-15 | >24 | <0.1 | <0.2% | White | >16 |

| Colorful zinc | Colorful-Zn | 10-15 | 72 | <0.1 | <0.1% | Multicolor | >24 |

| Nickel | Ni | 10-20 | 4 | <0.5 | <0.3% | Silver | >16 |

| Double nickel | Divalent-Ni | 15-20 | 24 | <0.2 | <0.3% | Silver | >16 |

| Nickel-copper-nickel | Ni-Cu-Ni | 15-30 | >48 | <0.1 | <0.1% | Silver | >42 |

| Zinc-nickel alloy | Zn-Ni alloy | 10-20 | >720 | <0.1 | <0.1% | Various colors | >72 |

| Third-party epoxy | Epoxy | 10-50 | >300 | - | - | Black | >24 |

| Electroless nickel | electroless Ni | <1 | >72 | - | - | Silver | >24 |

Salt chamber test: 37-39°C 5% NaCl PH 6.5-7.0 1.5 ml/Hr

PCT: 120°C, 2atm, 100% RH, 12Hr.

Appearance and characteristics

φ10mm×10mm |

Element symbol |

Element name |

Properties |

Usage |

|---|---|---|---|---|

|

3CrZn | Trivalent chromium zinc | Recently hexavalent chromium has been recognized as an environmentally damaging substance and replaced by trivalent chromium | Electronic parts, industrial tool parts |

|

Ag | Silver | Silver has the best electrical conductivity of all metals, low contact resistance, and good solderability, but is easy to discolor. | Electronic parts, Connectors, Dishes, Accessories |

|

Au | Gold | Gold has good corrosion and oxidation resistance and low electrical resistance. | Electronic parts, Electrical parts, Decorations, Accessories |

|

Cr | Chrome | Chrome has good abrasion and oxidation resistance and does not lose its shine in the atmosphere. | Exterior parts, Medical supplies, Audiovisual equipment, Accessories |

|

Cu | Copper | Copper discolors easily, so it is used as a base. Used to fill dents and add shine. | Cast products, ABS resin base |

|

CuZn | Bronze | Brass materials change color easily and are usually used as an undercoat. Brass materials are often used in ancient ornaments. | Ancient colorful ornaments |

|

Ni | Nickel | Nickel is chemically stable and has good anti-corrosion properties. It can be used for many different purposes and is used as a base for gold plating, chrome plating, etc. May cause skin irritation. | Electronic parts, Connectors, Base plating, Accessories |

|

NiBlack | Black nickel | Black nickel is an alloy coating made of nickel, zinc, and sulfur. The color may vary depending on the type of plating used as an undercoat. | Decorations, Accessories |

|

Sn | Tin | Tin has excellent anti-corrosion properties and does not oxidize easily. It does not lose its shine easily and can be safely used in food products. | Food dishes, Cans, Tin items, Decorations, Accessories |

|

Rh | Rhodium | Rhodium has excellent anti-corrosion properties and does not oxidize easily. It does not lose its shine easily and can be safely used in food products. | Electronic parts, Electrical parts, Audio parts, Decorations, Accessories |

|

- | Untreated | No surface treatment coating. Rust will easily develop on neodymium magnets. | |

|

- | Nylon | Made without organic solvents and used in food processors and medical devices. Passed the food hygiene act. | Toys, Small items |

|

- | Polyamide MF305 | High impact strength, bending resistance, and possibility of use at high temperature. | Electronic parts, Small items, For bending after painting |

| - | - | Epoxy MF304 | High resin hardness / Flame retardancy adjustment: UL94 / V-0 Certified | |

| - | - | Epoxy MF303 | High resin hardness / Easy to polish |

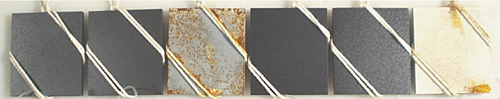

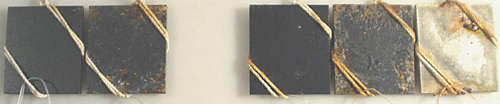

Rust resistance test Ni / Zu / Epoxy resin

| Dhit | Company [S] | Other companies | Dhit | Company [T] | Dhit | |

|---|---|---|---|---|---|---|

| Duration | HDC coating, Epoxy resin, MF304 | Normal epoxy resin | Anti-corrosion Zn primer for Zn car | HDC, Epoxy resin coating, MF305 | epoxy resin | NiCuNi, 3 layers, nickel |

| Before starting test |

|

|||||

| After 72 hrs |

|

|||||

| After 312 hrs |

|

|||||

| After 504 hrs |

|

|||||

Salt chamber test: 37-39 °C 5% NaCl PH 6.5-7.0 1.5 ml/Hr

PCT: 120°C, 2atm, 100% RH, 12Hr.

Thermal stability and magnetic losses

Depending on temperature, we distinguish three different types of losses:

- reversible (can be undone)

- irreversible (cannot be undone)

- constant

Reversible temperature loss

- temperature area: slightly above maximum operating temperature,

- temperature area: slightly above maximum operating temperature

- magnet is less magnetic if it is hot

- it does not matter how often the magnet is heated and cooled

Irreversible loss

- temperature area: significantly above maximum operating temperature

- magnet is permanently weakened, even after cooling

- repeated heating at the same temperature does not strengthen irreversible losses

- magnetization of an irreversibly weakened magnet by a sufficiently strong external magnetic field can restore its original strength

Constant loss of magnetic properties

due to high temperature, the structure of neodymium magnets changes - magnetization is no longer possible

Engineering tables (advanced data)

| Mechanical properties | ||

|---|---|---|

| Young's Modulus (E) | 160 | GPa |

| Poisson's Ratio (ν) | 0.24 | - |

| Compressive strength | 1000 - 1100 | MPa |

| Tensile strength | 80 | MPa |

| Vickers Hardness (Hv) | 560 - 600 | Hv |

| Density | 7.4 - 7.6 | g/cm³ |

| Thermal properties | ||

|---|---|---|

| Specific heat | 460 | J/(kg·K) |

| Thermal conductivity | 6 - 9 | W/(m·K) |

| Expansion coefficient (parallel) | 5.2 x 10⁻⁶ | /°C |

| Expansion coefficient (perpendicular) | -0.8 x 10⁻⁶ | /°C |

| Standard geometric tolerances (ISO) | |

|---|---|

| Dimension (L, W, H) | ±0.05 mm (standard) / ±0.02 mm (precision) |

| Diameter (D) | ±0.05 mm |

| Flatness | < 0.05 mm |

| Parallelism | < 0.05 mm |

| Perpendicularity | < 1° |

| Magnetic unit converter | ||

|---|---|---|

| 1 Tesla (T) | 10,000 Gauss (G) | |

| 1 kA/m | 12.57 Oersted (Oe) | |

| 1 MGOe | 7.96 kJ/m³ | |

Maximum production dimensions for NdFeB magnets

| shape | sketch | parameters | ||||

|---|---|---|---|---|---|---|

| cylindrical magnet |

|

dimension | ||||

| D(mm) | L(mm) | magnetization direction | ||||

| all grades | 1.0 ~ 250 mm | ≤ 80 mm | axial or radial | |||

| ring magnet |

|

dimension | ||||

| D(mm) | P(mm) | L(mm) | magnetization direction | |||

| all grades | 2.5 ~ 250 mm | 0.8 ~ 230 mm | ≤ 80 mm | ≤ 80 mm | ||

| plate magnet |

|

dimension | ||||

| L(mm) | W(mm) | H(mm) | magnetization direction | |||

| all grades | ≤ 200 mm | ≤ 100 mm | ≤ 80 mm | ≤ 80 mm | ||

| segment |

|

dimension | ||||

| H(mm) | W(mm) | L(mm) | magnetization direction | |||

| all grades | ≤ 70 mm | ≤ 100 mm | ≤ 200 mm | ≤ 80 mm | ||

Magnetic properties of sintered neodymium magnets NdFeB

| material type | remanence | coercivity | actual intrinsic force | energy density | operating temperature | ||||

|---|---|---|---|---|---|---|---|---|---|

| Br(kGs) | Br(T) | (BH)max(MGOe) | (BH)max(KJ/m) | ||||||

| Min. - Max. | Min. - Max. | bHc(kOe) | bHc(kA/m) | iHc(kOe) | iHc(kA/m) | Min. - Max. | Min. - Max. | ||

| N30 | 10.8-11.2 | 1080-1120 | 9.8-10.5 | 780-836 | ≥12 | ≥955 | 28-30 | 223-239 | ≤ 80°C |

| N33 | 11.4-11.7 | 1140-1170 | 10.3-11 | 820-876 | ≥12 | ≥955 | 31-33 | 247-263 | ≤ 80°C |

| N35 | 11.7-12.1 | 1170-1210 | 10.8-11.5 | 860-915 | ≥12 | ≥955 | 33-35 | 263-279 | ≤ 80°C |

| N38 | 12.2-12.6 | 1220-1260 | 10.8-11.5 | 860-915 | ≥12 | ≥955 | 36-38 | 287-303 | ≤ 80°C |

| N40 | 12.6-12.9 | 1260-1290 | 10.5-12.0 | 860-955 | ≥12 | ≥955 | 38-40 | 303-318 | ≤ 80°C |

| N42 | 12.9-13.2 | 1290-1320 | 10.8-12.0 | 860-955 | ≥12 | ≥955 | 40-42 | 318-334 | ≤ 80°C |

| N45 | 13.2-13.7 | 1320-1370 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 43-45 | 342-358 | ≤ 80°C |

| N48 | 13.7-14.2 | 1370-1420 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 45-48 | 358-382 | ≤ 80°C |

| N50 | 14-14.6 | 1400-1460 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 47-51 | 374-406 | ≤ 80°C |

| N52 | 14.2-14.7 | 1420-1470 | 10.8-12.5 | 860-995 | ≥12 | ≥955 | 48-53 | 380-422 | ≤ 65°C |

| N54 | 14.5-15.1 | 1450-1510 | 10.8-12.5 | 860-995 | ≥12 | ≥876 | 51-55 | 406-438 | ≤ 80°C |

| N30M | 10.8-11.2 | 1080-1120 | 9.8-10.5 | 780-836 | ≥14 | ≥1114 | 28-30 | 223-239 | ≤100°C |

| N33M | 11.4-11.7 | 1140-1170 | 10.3-11 | 820-876 | ≥14 | ≥1114 | 31-33 | 247-263 | ≤100°C |

| N35M | 11.7-12.1 | 1170-1210 | 10.8-11.5 | 860-915 | ≥14 | ≥1114 | 33-35 | 263-279 | ≤100°C |

| N38M | 12.2-12.6 | 1120-1260 | 10.8-11.5 | 860-915 | ≥14 | ≥1114 | 36-38 | 287-303 | ≤100°C |

| N40M | 12.6-12.9 | 1260-1290 | 10.8-12 | 860-955 | ≥14 | ≥1114 | 38-40 | 303-318 | ≤100°C |

| N42M | 12.9-13.2 | 1290-1320 | 10.8-12.5 | 860-995 | ≥14 | ≥1114 | 40-42 | 318-334 | ≤100°C |

| N45M | 13.2-13.7 | 1320-1370 | 10.8-13 | 860-1035 | ≥14 | ≥1114 | 43-45 | 342-358 | ≤100°C |

| N48M | 13.7-14.2 | 1370-1420 | 10.8-12.5 | 860-995 | ≥14 | ≥1114 | 45-48 | 358-382 | ≤100°C |

| N50M | 14-14.6 | 1400-1460 | 10.8-12.5 | 860-995 | ≥14 | ≥1114 | 47-51 | 374-406 | ≤100°C |

| N27H | 10.2-10.6 | 1020-1060 | 9.5-10.1 | 756-804 | ≥17 | ≥1353 | 25-27 | 199-215 | ≤120°C |

| N30H | 10.8-11.2 | 1080-1120 | 10.1-10.6 | 804-844 | ≥17 | ≥1353 | 28-30 | 223-239 | ≤120°C |

| N33H | 11.4-11.7 | 1140-1170 | 10.3-11 | 820-876 | ≥17 | ≥1353 | 31-33 | 247-263 | ≤120°C |

| N35H | 11.7-12.1 | 1170-1210 | 10.8-11.5 | 860-915 | ≥17 | ≥1353 | 33-35 | 263-279 | ≤120°C |

| N38H | 12.2-12.6 | 1120-1260 | 10.8-11.5 | 860-915 | ≥17 | ≥1353 | 36-38 | 287-303 | ≤120°C |

| N40H | 12.6-12.9 | 1260-1290 | 10.8-12 | 860-955 | ≥17 | ≥1353 | 38-40 | 303-318 | ≤120°C |

| N42H | 12.9-13.2 | 1290-1320 | 10.8-12 | 860-955 | ≥17 | ≥1353 | 40-42 | 318-334 | ≤120°C |

| N44H | 13.2-13.6 | 1320-1360 | 10.8-13 | 860-1035 | ≥17 | ≥1353 | 42-44 | 334-350 | ≤120°C |

| N48H | 13.7-14.2 | 1370-1420 | 10.8-12.5 | 860-995 | ≥17 | ≥1353 | 45-48 | 358-382 | ≤120°C |

| N27SH | 10.2-10.6 | 1020-1060 | 9.5-10.1 | 756-804 | ≥20 | ≥1592 | 25-27 | 199-215 | ≤150°C |

| N30SH | 10.8-11.2 | 1080-1120 | 10.1-10.6 | 804-844 | ≥20 | ≥1592 | 28-30 | 223-239 | ≤150°C |

| N33SH | 11.4-11.7 | 1140-1170 | 10.3-11 | 820-876 | ≥20 | ≥1592 | 31-33 | 247-263 | ≤150°C |

| N35SH | 11.7-12.1 | 1170-1210 | 10.8-11.5 | 860-915 | ≥20 | ≥1592 | 33-35 | 263-279 | ≤150°C |

| N38SH | 12.2-12.6 | 1120-1260 | 10.8-11.5 | 860-915 | ≥20 | ≥1592 | 36-38 | 287-303 | ≤150°C |

| N40SH | 12.6-12.9 | 1260-1290 | 10.8-12.0 | 860-955 | ≥20 | ≥1592 | 38-40 | 303-318 | ≤150°C |

| N42SH | 12.9-13.2 | 1290-1320 | 10.8-12 | 860-955 | ≥20 | ≥1592 | 40-42 | 318-334 | ≤150°C |

| N45SH | 13.2-13.7 | 1320-1370 | 10.8-12.5 | 860-955 | ≥20 | ≥1592 | 43-45 | 342-358 | ≤150°C |

| N25UH | 9.8-10.2 | 980-1020 | 9.2-9.6 | 732-764 | ≥25 | ≥1990 | 23-25 | 183-199 | ≤180°C |

| N28UH | 10.4-10.8 | 1040-1080 | 9.8-10.2 | 780-812 | ≥25 | ≥1990 | 26-28 | 207-233 | ≤180°C |

| N30UH | 10.8-11.2 | 1080-1120 | 10.1-10.6 | 804-844 | ≥25 | ≥1990 | 28-30 | 223-239 | ≤180°C |

| N33UH | 11.4-11.7 | 1140-1170 | 10.3-11 | 820-876 | ≥25 | ≥1990 | 31-33 | 247-263 | ≤180°C |

| N35UH | 11.7-12.1 | 1170-1210 | 10.8-11.5 | 860-915 | ≥25 | ≥1990 | 33-35 | 263-279 | ≤180°C |

| N38UH | 12.2-12.6 | 1120-1260 | 10.8-11.5 | 860-915 | ≥25 | ≥1990 | 36-38 | 287-303 | ≤180°C |

| N40UH | 12.6-12.9 | 1260-1290 | 10.5-12.0 | 860-955 | ≥25 | ≥1990 | 38-40 | 303-318 | ≤180°C |

| N25EH | 9.8-10.2 | 980-1020 | 9.2-9.6 | 732-764 | ≥30 | ≥2388 | 23-25 | 183-199 | ≤200°C |

| N28EH | 10.4-10.8 | 1040-1080 | 9.8-10.2 | 780-812 | ≥30 | ≥2388 | 26-28 | 207-223 | ≤200°C |

| N30EH | 10.8-11.2 | 1080-1120 | 10.1-10.6 | 804-844 | ≥30 | ≥2388 | 28-30 | 223-239 | ≤200°C |

| N33EH | 11.4-11.7 | 1140-1170 | 10.3-11 | 820-876 | ≥30 | ≥2388 | 31-33 | 247-263 | ≤200°C |

| N35EH | 11.7-12.1 | 1170-1210 | 10.8-11.5 | 860-915 | ≥30 | ≥2388 | 33-35 | 263-279 | ≤200°C |

| N38EH | 12.2-12.5 | 1120-1250 | ≥11.3 | ≥899 | ≥30 | ≥2388 | 36-39 | 287-310 | ≤200°C |

| N40EH | 12.5-12.8 | 1250-1280 | ≥11.6 | ≥923 | ≥30 | ≥2388 | 38-41 | 302-326 | ≤200°C |

| N42EH | 12.8-13.2 | 1280-1320 | ≥11.7 | ≥931 | ≥30 | ≥2388 | 40-43 | 318-342 | ≤200°C |

| N28AH | 10.4-10.8 | 1040-1080 | ≥9.9 | ≥787 | ≥33 | ≥2624 | 26-29 | 207-231 | ≤230°C |

| N30AH | 10.8-11.3 | 1080-1130 | ≥10.3 | ≥819 | ≥33 | ≥2624 | 28-31 | 223-247 | ≤230°C |

| N33AH | 11.3-11.7 | 1130-1170 | ≥10.6 | ≥843 | ≥33 | ≥2624 | 31-34 | 247-271 | ≤230°C |

| N35AH | 11.7-12.2 | 1170-1120 | ≥11.0 | ≥876 | ≥33 | ≥2624 | 33-36 | 263-287 | ≤230°C |

| N38AH | 12.2-12.5 | 1120-1250 | ≥11.3 | ≥899 | ≥33 | ≥2624 | 36-39 | 287-310 | ≤230°C |

| N40AH | 12.5-12.8 | 1250-1280 | ≥11.6 | ≥923 | ≥33 | ≥2624 | 38-41 | 302-326 | ≤230°C |

* The above-mentioned data regarding magnetic and physical properties are given at room temperature (20°C). The maximum operating temperature of the magnet may change due to the length-to-diameter ratio, coating thickness, and other environmental factors. Additional grades are available. Please contact us for information.

Temperature properties of neodymium magnets

The table below contains information about the maximum operating temperature (Maximum Operating Temperature) and Curie temperature (Curie Temperature) for individual grades ("N Grade"). Knowledge of these parameters is particularly important when selecting a magnet for applications in elevated temperature conditions.

| magnet type/grade | maximum operating temperature | Curie temperature |

|---|---|---|

| N | 80°C / 176°F | 310°C / 590°F |

| NM | 100°C / 212°F | 340°C / 644°F |

| NH | 120°C / 248°F | 340°C / 644°F |

| NSH | 150°C / 302°F | 340°C / 644°F |

| NUH | 180°C / 356°F | 350°C / 662°F |

| NEH | 200°C / 392°F | 350°C / 662°F |

| NAH | 230°C / 446°F | 350°C / 662°F |