Among non-standard magnets (not just neodymium), we also have:

Neodymium magnets can be manufactured:

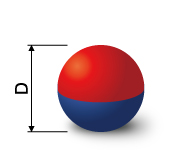

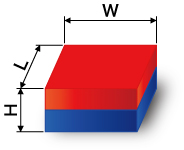

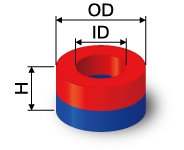

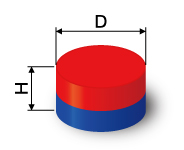

- in the shape of a cuboid, cube, cylinder, circle, sphere, arc, or more complex shapes,

- with dimensions from 0.6 to 200 mm,

- magnetized in the direction of thickness, width, length, diameter, or with more complex multi-pole magnetization - (see technology),

- magnets with a screw hole, with a sticker, with a hook, or an eyelet,

- with surface treatment: nickel, zinc, chrome, gold, epoxy resin, rubber, plastic, or without surface treatment,

- with thermal resistance up to 240 oC for neo NdFeB magnets (for SmCo magnets 350oC and AlNiCo up to 550oC),

- with North pole marking by a line, red dot, laser burning, or without marking,

- with pull-off force from 0.05 kg to 5000 kg,

- from material N27 to N55 (we offer from N38 upwards - if N24 is needed, competitors have such ones)...

In addition to neodymium magnets, we can also manufacture AlNiCo, SmCo, and ferrite magnets.

Before sending us your inquiry and request for a quote, list all information about your idea, project, and the quantity of magnets you need for the order. Define the purpose, intended use, and quality of materials you want us to use when creating your project. It is very important that your project is described as well as possible in the initial planning stage.

Using our order form, located on our website at https://info.dhit.pl, send us all the necessary information. Remember that the more guidelines and precise data you provide, the more accurately we can quote your project and send you an optimal offer to minimize execution and transport costs. When sending us an inquiry, remember to provide the most important information, namely:

- Magnet type (cylindrical, flat, ring, other),

- Size (expressed in millimetres),

- Specify the material density the magnet should be made of (standard is N 38),

- Specify the magnet's operating temperature (standard is 80oC),

- Specify the type of coating the magnet should be covered with (standard is nickel coating)

- Specify the quantity of magnets,

- Attach a technical drawing.

The accuracy of your inquiry and the materials you send will allow us to respond as quickly as possible and create a unique offer for you.

Your order will be processed. Simply put, our specialists in Ożarów Mazowiecki will sit down and thoroughly analyze your project to determine what materials we should use for its implementation, what types of execution processes will be involved, and how much time we will need to complete the required quantity of your order. We will determine the final price of a single product and the entire order batch. This may take a moment, so we will keep you informed of the progress of your project. You will usually receive an offer from us within 3 days of submitting your inquiry at the latest.

Once we conduct a detailed analysis and cost estimate, we will send you a precise offer, with all the data, execution specification, and price. If we agree on the details and our offer is a bulls-eye, your order will be executed! Production time depends on the production load and takes 25 to 35 days.

Your project and order will be carefully checked for correctness and tightly and precisely packed to ensure that your products are safe during transport and will not suffer any damage. We make sure that all orders reach our clients in undamaged packaging. Within 2-3 business days from the packaging date, you will receive your order at the address you provided.

We believe everyone is a specialist in their field, which is why we have prepared individual project packages for every client, from Warsaw to Gdańsk, thanks to which we are able to design and build any order and create any shape and size with high magnetic power.

What you need to do to order custom-sized magnets?

Unique Magnet

| Produkty standardowe | Średnica zewnętrzna D, OD | ID średnicy wewnętrznej | Długość L | Szerokość W | Wysokość H |

|---|---|---|---|---|---|

| < 5mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| < 10mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| < 20mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| < 50mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm | ±0.1mm |

| <100mm | ±0.15mm | ±0.15mm | ±0.15mm | ±0.15mm | ±0.15mm |

| >100mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm | ±0.2mm |

| Produkty na zamówienie | Średnica zewnętrzna D, OD | ID średnicy wewnętrznej | Długość L | Szerokość W | Wysokość H | |

|---|---|---|---|---|---|---|

| < 5mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | |

| < 10mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | |

| ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm |

Sizes that can be manufactured for neodymium magnets

The sizes that can be manufactured depend on the material grade. Currently, the maximum possible length is 150 mm. Due to object limitations, it may not be possible to manufacture large items from materials other than N35. For special projects, we offer high-temperature materials (H, SH, EH, UH).

| Dyski / Walce | D Średnica | Wysokość H, Grubość T | Kierunek namagnesowania |

|---|---|---|---|

| Maksymalnie | 200 mm | 30 mm | Wysokość H, średnica D |

| Minimum | 1 mm | 0,5 mm | Wysokość H, średnica D |

| Pierścienie | OD Zewnętrzna średnica | ID Średnica wewnętrzna | Wysokość H, Grubość T | Kierunek namagnesowania |

|---|---|---|---|---|

| Minimum 1 | 200 mm | 180 mm | 40 mm | Wysokość H |

| Maksymalnie 2 | 90 mm | 70 mm | 80 mm | Średnica D |

| Minimum | 3 mm | 1 mm | 1 mm | Wysokość H, średnica D |

| Kwadraty | Długość L | Szerokość W | Wysokość H, Grubość T | Kierunek namagnesowania |

|---|---|---|---|---|

| Maksymalny wymiar 1 |

245 mm | 80 mm | 40 mm | Wysokość H |

| Maksymalny wymiar 2 | 150 mm | 100 mm | 44 mm | Wysokość H |

| Minimum | 1 mm | 1 mm | 1 mm | Wysokość H |