Magnetic bar (separator) - technical specification

analysis of physical parameters, construction, and filtration efficiency

In our separators, we use a casing tube with a wall thickness of 1.0 mm. Versions with 0.5 mm are found on the market, allowing for a higher Gauss reading (smaller air gap) but drastically reducing lifespan. The 0.5 mm wall wears through quickly (abrasion) due to the flowing medium, leading to leakage, product contact with magnets, and neodymium corrosion. The 1 mm wall is an engineering compromise guaranteeing process safety while maintaining high induction.

Induction selection depends on the impurity fraction. The table below presents capture efficiency:

| Model | Absorption point | Fine paramagnetic dust | Short range | Long range (penetration) |

|---|---|---|---|---|

| [φ25 mm] ~ 8000 Gs | TAK | TAK | TAK | - |

| [φ28 mm] ~ 9000 Gs | TAK | TAK | TAK | TAK (Medium) |

| [φ32 mm] ~ 10000 Gs | TAK | TAK | TAK | TAK (Strong) |

Magnetic field density (number of poles per meter) defines the filtration class. Bars with a power of ~10,000 Gs (dia 32mm) generate a dense field capable of polarizing and capturing weakly magnetic particles (e.g., iron oxides, worn stainless steel).

| Model | Process application |

|---|---|

| [φ25 mm] ~ 8000 Gs | Pre-filtration (machine protection) |

| [φ32 mm] ~ 10000 Gs | Final filtration (HACCP quality control) |

Surface induction (Gauss) is not the only parameter. The field gradient ($dH/dx$) is key. Bars with a larger diameter (dia 32mm) contain larger magnets, generating a field with a wider radius of action, penetrating deeper into the product stream.

8000 Gauss (dia 18-25mm): Effective for ferromagnetics >1mm (screws, washers, wire).

10000 Gauss (dia 32mm): Essential for filings <0.5mm and materials with low magnetic susceptibility (e.g., scale, filings after acid-resistant steel processing).

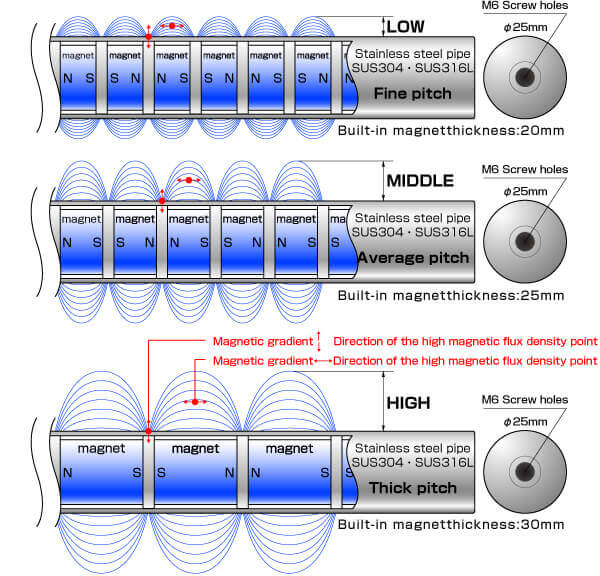

Impurities do not settle evenly but at points of the highest field gradient – at the pole junction (pole pieces). Our bar design maximizes the number of these points while maintaining appropriate range.

Visualization of pole boundaries.

Physical distribution of force lines.

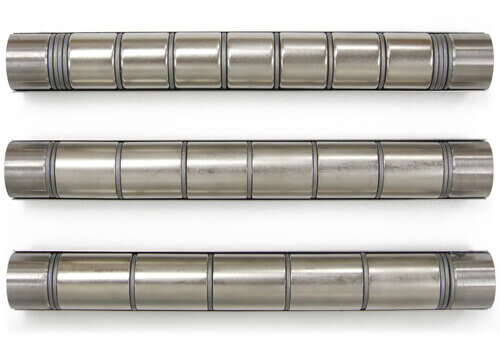

Internal arrangement (magnetic stack).

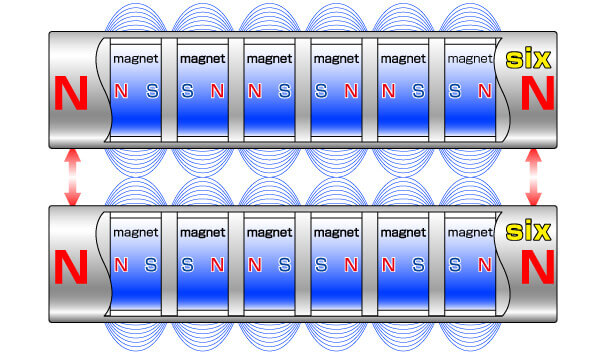

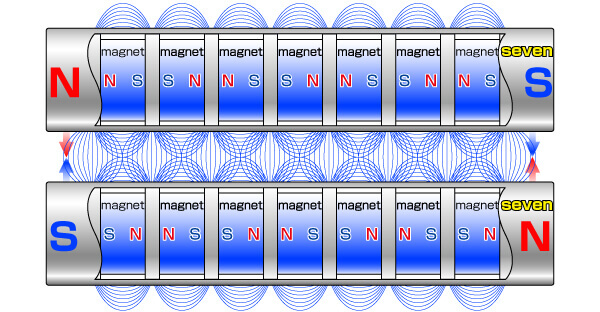

When building grids (drawer filters), the polarization of adjacent bars is crucial. They must be arranged so that the fields attract (close) rather than repel, which would create dead filtration zones.

Incompatible arrangement (Reflection)

Compatible arrangement (Adsorption)

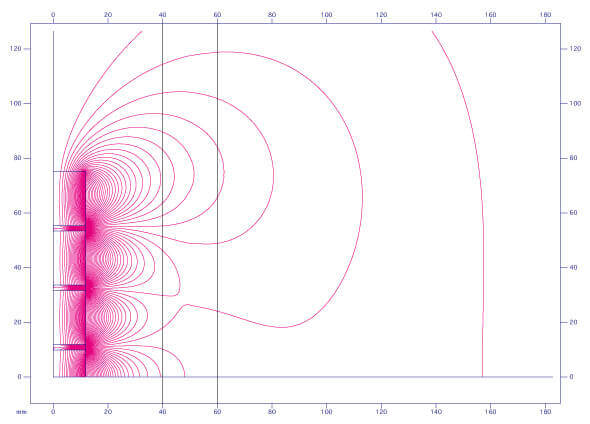

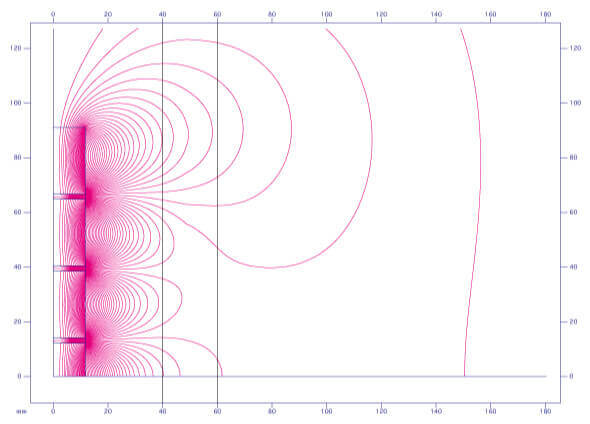

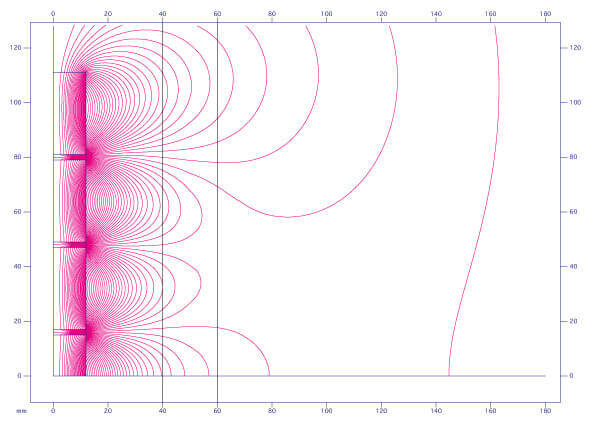

Finite Element Method analysis shows how the magnet pitch affects the shape of the magnetic field around the tube.

20 mm (Fine)

25 mm (Regular)

30 mm (Coarse)

AISI 304 (1.4301): Industrial standard. Suitable for dry environments, neutral pH.

AISI 316L (1.4404): Steel with molybdenum addition. Essential in chemically aggressive environments, in the presence of chlorides (salt) and organic acids (fruit and vegetable processing).

| Steel grade | Corrosion resistance | Recommended environment |

|---|---|---|

| AISI 304 | Dobry | Standard (dry food, plastics) |

| AISI 316L | Bardzo Dobry | Aggressive (chemicals, brines, juices) |

We produce bars in standard diameters. The maximum length of a single element is 500 mm.

| Diameter (Ø) | Mounting thread | Max Length | Induction (Gauss) |

|---|---|---|---|

| φ18 mm | M8 | 500 mm | ~ 8000 |

| φ22 mm | M8 | 500 mm | ~ 8000 |

| φ25 mm | M8 | 500 mm | ~ 10000 |

| φ28 mm | M8 | 500 mm | ~ 9000 |

| φ32 mm | M8 | 500 mm | ~ 10000 |

* We make custom lengths on order up to 500mm. Length tolerance +/- 1mm.

The Gauss value (B) alone does not generate force. The attraction force ($F$) is the product of induction and field gradient ($F = m * B * dB/dx$). Our separators are designed to maximize the gradient right at the tube surface, allowing impurities to be 'ripped' from the fast-flowing product stream.

Standard neodymium magnets (N) lose approx. 0.11% of induction for every 1°C temperature increase. Operation above 80°C risks irreversible power loss. For hot applications (e.g., plastic granules after dryer), we use high-temperature materials (H, SH, UH), which maintain stability up to 120°C, 150°C, or 180°C.

Stainless steel filings (e.g., 304) subjected to mechanical processing (cutting, crushing) change their crystal structure and become paramagnetic (weakly magnetic). To catch them, the separator must generate induction above 10,000 Gauss and a high field gradient. We dedicate 32 mm diameter bars for this purpose.

The magnetic force must overcome the momentum force of the product stream. For gravitational free fall (chutes), using several rows of bars or deflectors slowing down the flow is recommended. For pressurized liquids, the maximum recommended flow velocity is 1.5 - 2.0 m/s for effective separation of particles <1mm.

In high-viscosity products (chocolate, pastes, oils), medium resistance hinders the migration of a metal particle to the magnet surface. In such applications, it is crucial to use bars with the largest possible diameter (dia 32mm), generating a field reaching deep into the product, and reducing flow velocity.

Installing a magnetic bar in a pipeline constitutes a cross-section narrowing. The pressure drop dependent on the medium viscosity and the degree of pipe 'obstruction' by the filter must be taken into account. In engineering projects, we recommend increasing the pipeline diameter in the filtration section to maintain constant flow.

For the food and pharmaceutical industries, surface roughness is crucial. Our bars are polished to Ra < 0.8 µm (sanitary standard), which prevents product adhesion and bacterial growth, and facilitates cleaning.

Manual cleaning of bars from filings is time-consuming. In 'Easy Clean' versions, the magnetic bar moves inside an additional, thin-walled casing tube. Pulling out the magnetic core causes the filings to fall off by themselves. This system is recommended for frequent contamination.

When separating highly abrasive materials (quartz sand, cullet, ceramics), standard 304 steel may wear through. In such cases, we recommend increasing wall thickness or using special hardening coatings (e.g., nitriding) to extend the separator's life.

According to ISO and HACCP standards, separators should be periodically tested. We offer a validation service using a certified teslameter, checking if the surface induction has not fallen below critical values. Tests should be performed at least once a year.

Magnetic separators can work in dust explosion hazard zones (zone 20, 21, 22), provided that grounding (electrostatic discharge) and cleaning procedures preventing sparking upon metal-to-metal impact are ensured. Antistatic bars should be used.

A strong magnetic field (10k Gs) fades quickly with distance, but in immediate proximity (up to 10-15 cm), it can disrupt the operation of inductive sensors, inverters, or PLC controllers. We recommend maintaining a safe mounting distance from control cabinets.