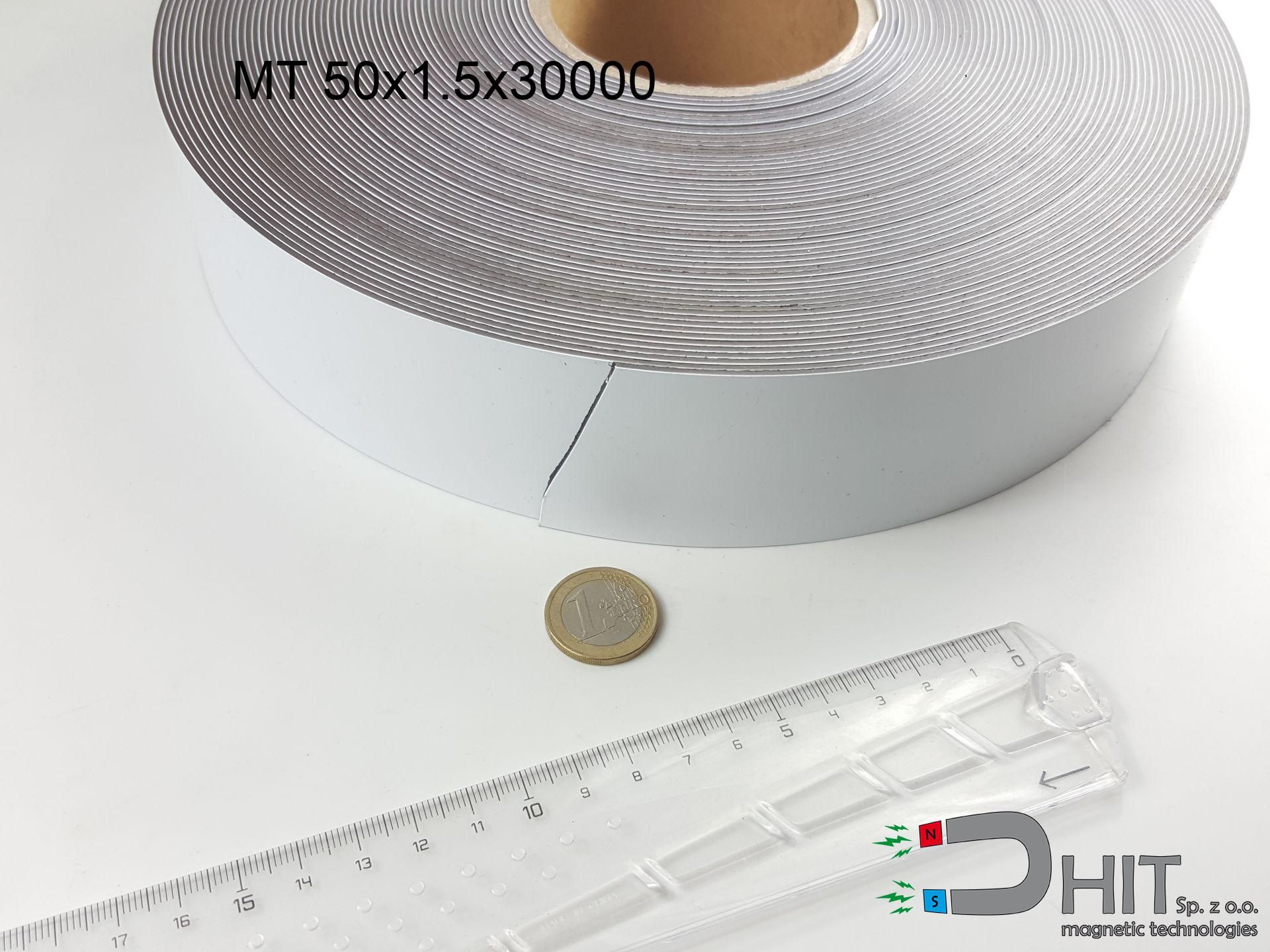

MT 50x1.5x30000 - magnetic tape

magnetic tape

Catalog no 380510

length [±0,1 mm]

50 mm

Width [±0,1 mm]

1.5 mm

Height [±0,1 mm]

30000 mm

Magnetization Direction

↔ radial

258.30 ZŁ with VAT / pcs + price for transport

210.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?Not sure which magnet to buy?

Call us now

+48 888 99 98 98

otherwise get in touch by means of

contact form

our website.

Parameters and form of magnetic components can be analyzed with our

modular calculator.

Orders submitted before 14:00 will be dispatched today!

MT 50x1.5x30000 - magnetic tape

Magnetic properties of material

Physical properties of NdFeB

Shopping tips

Advantages as well as disadvantages of neodymium magnets NdFeB.

In addition to their magnetic capacity, neodymium magnets provide the following advantages:

- They do not lose their magnetism, even after nearly ten years – the decrease of lifting capacity is only ~1% (based on measurements),

- They show strong resistance to demagnetization from outside magnetic sources,

- In other words, due to the glossy nickel coating, the magnet obtains an aesthetic appearance,

- They exhibit elevated levels of magnetic induction near the outer area of the magnet,

- Thanks to their enhanced temperature resistance, they can operate (depending on the shape) even at temperatures up to 230°C or more,

- Thanks to the flexibility in shaping and the capability to adapt to individual requirements, neodymium magnets can be created in various configurations, which broadens their application range,

- Wide application in new technology industries – they find application in HDDs, electric motors, diagnostic apparatus as well as sophisticated instruments,

- Relatively small size with high magnetic force – neodymium magnets offer impressive pulling strength in small dimensions, which allows for use in compact constructions

Disadvantages of magnetic elements:

- They can break when subjected to a heavy impact. If the magnets are exposed to physical collisions, they should be placed in a protective enclosure. The steel housing, in the form of a holder, protects the magnet from breakage while also strengthens its overall robustness,

- Magnets lose field strength when exposed to temperatures exceeding 80°C. In most cases, this leads to irreversible power drop (influenced by the magnet’s dimensions). To address this, we provide [AH] models with superior thermal resistance, able to operate even at 230°C or more,

- Due to corrosion risk in humid conditions, it is recommended to use sealed magnets made of plastic for outdoor use,

- The use of a protective casing or external holder is recommended, since machining multi-axis shapes in neodymium magnets is risky,

- Possible threat due to small fragments may arise, especially if swallowed, which is important in the health of young users. It should also be noted that miniature parts from these assemblies may hinder health screening when ingested,

- In cases of large-volume purchasing, neodymium magnet cost is a challenge,

Breakaway strength of the magnet in ideal conditions – what contributes to it?

The given holding capacity of the magnet corresponds to the highest holding force, assessed under optimal conditions, that is:

- with the use of low-carbon steel plate acting as a magnetic yoke

- having a thickness of no less than 10 millimeters

- with a smooth surface

- in conditions of no clearance

- with vertical force applied

- under standard ambient temperature

Lifting capacity in real conditions – factors

In practice, the holding capacity of a magnet is conditioned by these factors, from crucial to less important:

- Air gap between the magnet and the plate, as even a very small distance (e.g. 0.5 mm) causes a drop in lifting force of up to 50%.

- Direction of applied force, because the maximum lifting capacity is achieved under perpendicular application. The force required to slide the magnet along the plate is usually several times lower.

- Thickness of the plate, as a plate that is too thin causes part of the magnetic flux not to be used and to remain wasted in the air.

- Material of the plate, because higher carbon content lowers holding force, while higher iron content increases it. The best choice is steel with high magnetic permeability and high saturation induction.

- Surface of the plate, because the more smooth and polished it is, the better the contact and consequently the greater the magnetic saturation.

- Operating temperature, since all permanent magnets have a negative temperature coefficient. This means that at high temperatures they are weaker, while at sub-zero temperatures they become slightly stronger.

* Lifting capacity was measured by applying a smooth steel plate of suitable thickness (min. 20 mm), under perpendicular detachment force, however under parallel forces the lifting capacity is smaller. In addition, even a small distance {between} the magnet and the plate decreases the load capacity.

Notes with Neodymium Magnets

Magnets made of neodymium are highly delicate, they easily fall apart and can become damaged.

Magnets made of neodymium are fragile and will break if allowed to collide with each other, even from a distance of a few centimeters. They are coated with a shiny nickel plating similar to steel, but they are not as hard. At the moment of connection between the magnets, tiny sharp metal pieces can be propelled in various directions at high speed. Eye protection is recommended.

Under no circumstances should neodymium magnets be brought close to GPS and smartphones.

Magnetic fields can interfere with compasses and magnetometers used in aviation and maritime navigation, as well as internal compasses of smartphones and GPS devices. There are neodymium magnets in every smartphone, for example, in the microphone and speakers.

Neodymium magnets can demagnetize at high temperatures.

Although magnets have demonstrated their effectiveness up to 80°C or 175°F, the temperature can vary depending on the type, shape, and intended use of the specific magnet.

The magnet is coated with nickel. Therefore, exercise caution if you have an allergy.

Studies clearly indicate a small percentage of people who suffer from metal allergies such as nickel. An allergic reaction often manifests as skin redness and rash. If you have a nickel allergy, you can try wearing gloves or simply avoid direct contact with nickel-plated neodymium magnets.

Neodymium magnets are among the strongest magnets on Earth. The astonishing force they generate between each other can surprise you.

Read the information on our website on how to properly utilize neodymium magnets and avoid significant harm to your body and unintentional damage to the magnets.

Magnets will attract to each other, so remember not to allow them to pinch together without control or place your fingers in their path.

Magnets may crack or alternatively crumble with uncontrolled joining to each other. You can't move them to each other. At a distance less than 10 cm you should hold them very firmly.

Neodymium magnets should not be near people with pacemakers.

In the case of neodymium magnets, there is a strong magnetic field. As a result, it interferes with the operation of a heart pacemaker. However, if the magnetic field does not affect the device, it can damage its components or deactivate the device when it is in a magnetic field.

It is important to keep neodymium magnets away from youngest children.

Neodymium magnets are not toys. Be cautious and make sure no child plays with them. They can be a significant choking hazard. If multiple magnets are swallowed, they can attract to each other through the intestinal walls, causing significant injuries, and even death.

Keep neodymium magnets away from TV, wallet, and computer HDD.

Strong magnetic fields emitted by neodymium magnets can destroy magnetic storage media such as floppy disks, credit cards, magnetic ID cards, cassette tapes, video tapes, or other devices. In addition, they can damage televisions, VCRs, computer monitors, and CRT displays. Avoid placing neodymium magnets in close proximity to electronic devices.

Dust and powder from neodymium magnets are flammable.

Avoid drilling or mechanical processing of neodymium magnets. If the magnet is crushed into fine powder or dust, it becomes highly flammable.

Caution!

So you are aware of why neodymium magnets are so dangerous, read the article titled How dangerous are powerful neodymium magnets?.