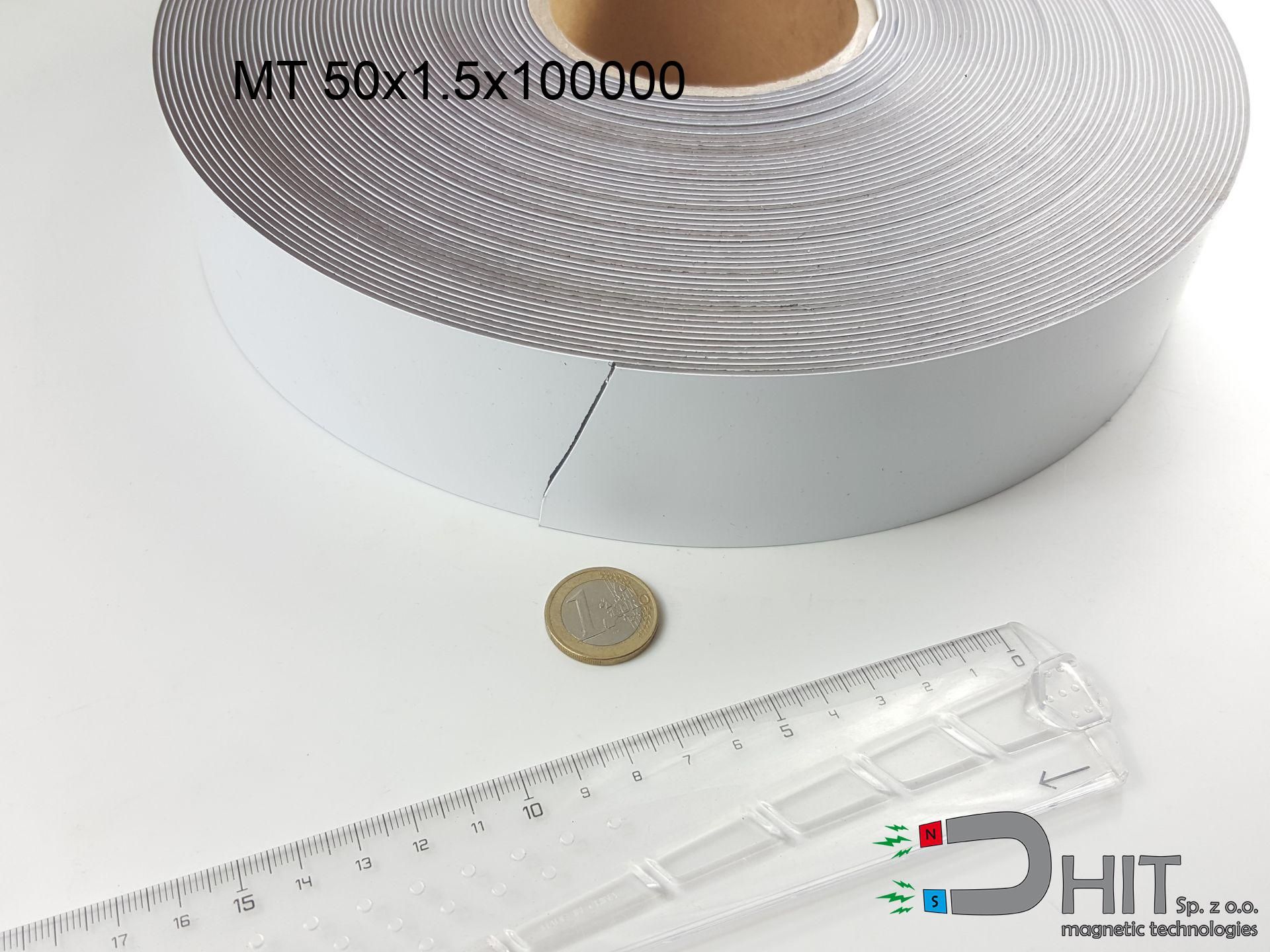

MT 50x1.5x100000 - magnetic tape

magnetic tape

Catalog no 380512

length [±0,1 mm]

50 mm

Width [±0,1 mm]

1.5 mm

Height [±0,1 mm]

100000 mm

Magnetization Direction

↔ radial

861.00 ZŁ with VAT / pcs + price for transport

700.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?Not sure about your choice?

Give us a call

+48 888 99 98 98

if you prefer contact us via

our online form

the contact form page.

Specifications along with shape of neodymium magnets can be calculated on our

power calculator.

Orders placed before 14:00 will be shipped the same business day.

MT 50x1.5x100000 - magnetic tape

Magnetic properties of material

Physical properties of NdFeB

Shopping tips

Advantages and disadvantages of neodymium magnets NdFeB.

Apart from their consistent magnetism, neodymium magnets have these key benefits:

- They have unchanged lifting capacity, and over nearly 10 years their attraction force decreases symbolically – ~1% (in testing),

- They remain magnetized despite exposure to magnetic surroundings,

- The use of a decorative gold surface provides a eye-catching finish,

- Magnetic induction on the surface of these magnets is impressively powerful,

- These magnets tolerate elevated temperatures, often exceeding 230°C, when properly designed (in relation to build),

- The ability for precise shaping or customization to custom needs – neodymium magnets can be manufactured in multiple variants of geometries, which amplifies their functionality across industries,

- Key role in new technology industries – they are utilized in HDDs, rotating machines, healthcare devices as well as other advanced devices,

- Thanks to their concentrated strength, small magnets offer high magnetic performance, while occupying minimal space,

Disadvantages of neodymium magnets:

- They are prone to breaking when subjected to a heavy impact. If the magnets are exposed to mechanical hits, it is suggested to place them in a metal holder. The steel housing, in the form of a holder, protects the magnet from damage and reinforces its overall robustness,

- High temperatures may significantly reduce the magnetic power of neodymium magnets. Typically, above 80°C, they experience permanent decline in performance (depending on form). To prevent this, we offer heat-resistant magnets marked [AH], capable of working up to 230°C, which makes them perfect for high-temperature use,

- Magnets exposed to humidity can oxidize. Therefore, for outdoor applications, we suggest waterproof types made of coated materials,

- Using a cover – such as a magnetic holder – is advised due to the challenges in manufacturing complex structures directly in the magnet,

- Possible threat linked to microscopic shards may arise, when consumed by mistake, which is notable in the context of child safety. Additionally, tiny components from these magnets might complicate medical imaging when ingested,

- Due to a complex production process, their cost is above average,

Maximum holding power of the magnet – what it depends on?

The given holding capacity of the magnet means the highest holding force, calculated in ideal conditions, specifically:

- with the use of low-carbon steel plate acting as a magnetic yoke

- of a thickness of at least 10 mm

- with a polished side

- with zero air gap

- with vertical force applied

- under standard ambient temperature

What influences lifting capacity in practice

Practical lifting force is dependent on elements, by priority:

- Air gap between the magnet and the plate, because even a very small distance (e.g. 0.5 mm) causes a drop in lifting force of up to 50%.

- Direction of applied force, because the maximum lifting capacity is achieved under perpendicular application. The force required to slide the magnet along the plate is usually several times lower.

- Thickness of the plate, as a plate that is too thin causes part of the magnetic flux not to be used and to remain wasted in the air.

- Material of the plate, because higher carbon content lowers holding force, while higher iron content increases it. The best choice is steel with high magnetic permeability and high saturation induction.

- Surface of the plate, because the more smooth and polished it is, the better the contact and consequently the greater the magnetic saturation.

- Operating temperature, since all permanent magnets have a negative temperature coefficient. This means that at high temperatures they are weaker, while at sub-zero temperatures they become slightly stronger.

* Holding force was checked on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, in contrast under attempts to slide the magnet the load capacity is reduced by as much as 75%. Additionally, even a slight gap {between} the magnet’s surface and the plate reduces the holding force.

Handle Neodymium Magnets Carefully

Neodymium magnets can attract to each other, pinch the skin, and cause significant swellings.

If have a finger between or alternatively on the path of attracting magnets, there may be a severe cut or a fracture.

Avoid contact with neodymium magnets if you have a nickel allergy.

Studies clearly indicate a small percentage of people who suffer from metal allergies such as nickel. An allergic reaction often manifests as skin redness and rash. If you have a nickel allergy, try wearing gloves or avoid direct contact with nickel-plated neodymium magnets.

Dust and powder from neodymium magnets are highly flammable.

Do not attempt to drill into neodymium magnets. Mechanical processing is also not recommended. If the magnet is crushed into fine powder or dust, it becomes highly flammable.

Neodymium magnets can become demagnetized at high temperatures.

In certain circumstances, Neodymium magnets may experience demagnetization when subjected to high temperatures.

Neodymium magnets are the most powerful magnets ever created, and their power can shock you.

Make sure to review all the information we have provided. This will help you avoid harm to your body and damage to the magnets.

Avoid bringing neodymium magnets close to a phone or GPS.

Magnetic fields can interfere with compasses and magnetometers used in aviation and maritime navigation, as well as internal compasses of smartphones and GPS devices. There are neodymium magnets in every smartphone, for example, in the microphone and speakers.

Keep neodymium magnets away from people with pacemakers.

Neodymium magnets generate very strong magnetic fields that can interfere with the operation of a pacemaker. This is because many of these devices are equipped with a function that deactivates the device in a magnetic field.

Magnets made of neodymium are noted for being fragile, which can cause them to crumble.

Neodymium magnets are fragile as well as will crack if allowed to collide with each other, even from a distance of a few centimeters. Despite being made of metal as well as coated with a shiny nickel plating, they are not as hard as steel. At the moment of connection between the magnets, small sharp metal fragments can be propelled in various directions at high speed. Eye protection is recommended.

Under no circumstances should neodymium magnets be placed near a computer HDD, TV, and wallet.

Neodymium magnets generate strong magnetic fields that can destroy magnetic media such as floppy disks, video tapes, HDDs, credit cards, magnetic ID cards, cassette tapes, or other devices. They can also destroy videos, televisions, CRT computer monitors. Remember not to place neodymium magnets close to these electronic devices.

Do not give neodymium magnets to children.

Remember that neodymium magnets are not toys. Be cautious and make sure no child plays with them. In the case of swallowing multiple magnets simultaneously, they can attract to each other through the intestinal walls. In the worst case scenario, this can lead to death.

Safety precautions!

Please see the article - What danger lies in neodymium magnets? You will learn how to handle them properly.